In today’s competitive industrial environment, many factories still rely on decades-old machines. While these machines are mechanically strong, their outdated control systems cause frequent breakdowns, high maintenance costs, energy waste, and production inefficiencies. Modern PLC machine upgrades offer a powerful solution by revitalizing old equipment, improving efficiency, reducing downtime, and future-proofing operations for today’s smart manufacturing needs.

At Aknitech, we specialize in restoring old machines with modern PLCs and advanced automation solutions. Our legacy system upgrade services help manufacturers breathe new life into outdated equipment, transforming them into efficient, reliable, and future-ready assets.

Why Upgrading Legacy Machines is Crucial

1. Rising Downtime and Maintenance Costs

Older machines are prone to unexpected failures due to aging electrical components, worn-out wiring, and unavailable spare parts. These breakdowns lead to costly downtime, disrupted production schedules, and increased repair expenses.

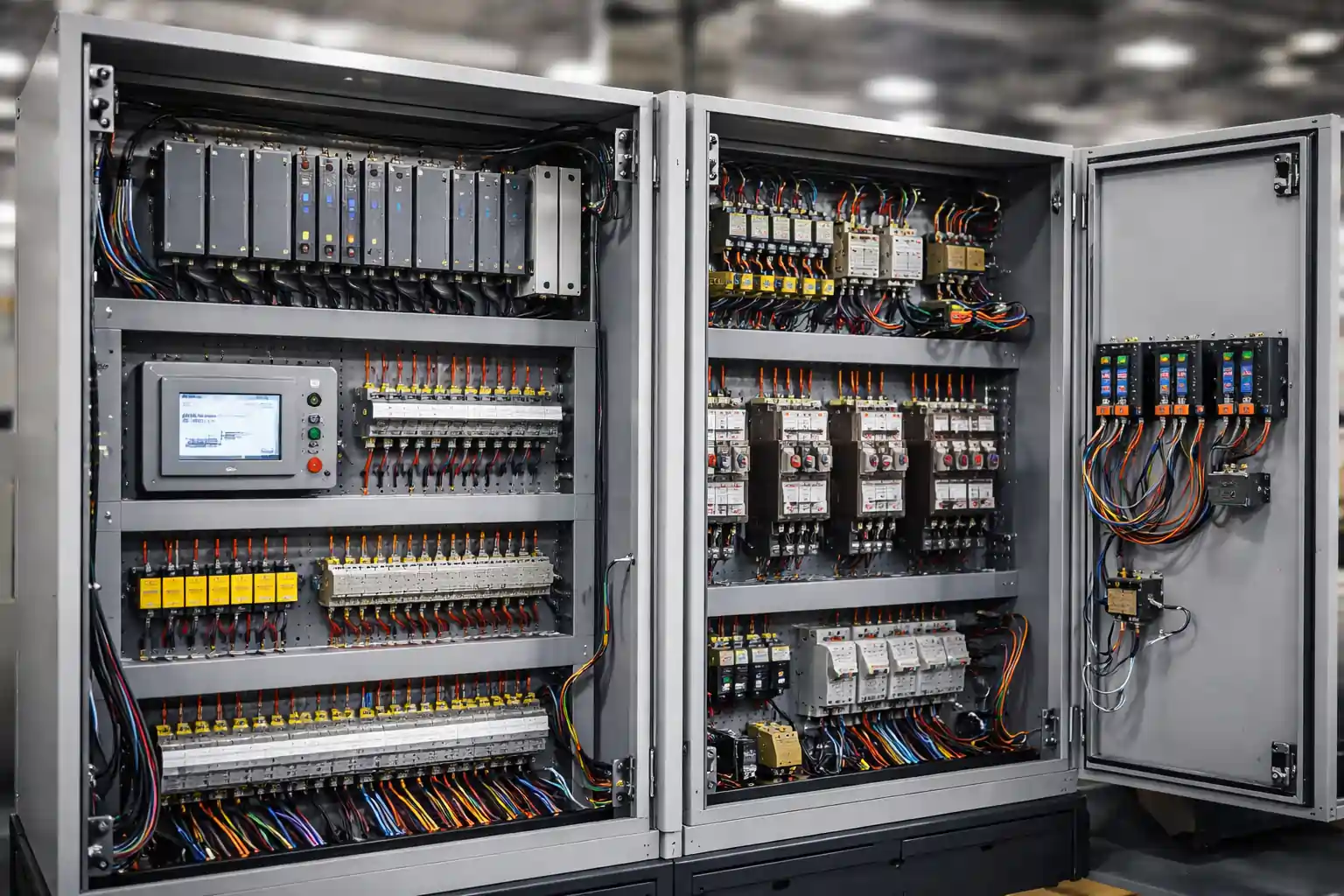

By upgrading to modern PLC electrical panels, companies gain more reliable control systems that significantly reduce unplanned outages.

2. Limited Production Data and Control

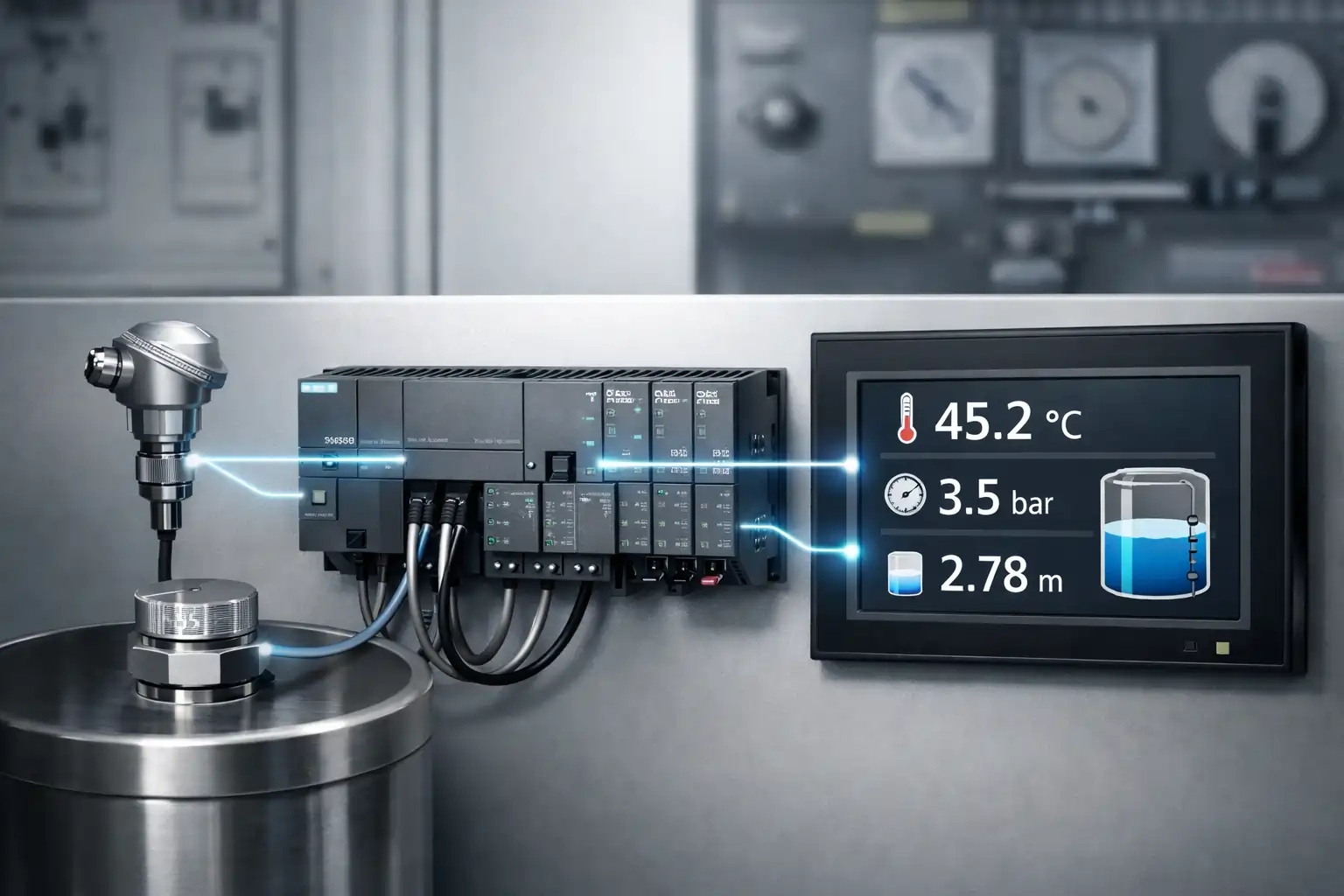

Legacy systems lack advanced monitoring features and cannot provide real-time data insights. This makes it difficult for operators and managers to identify bottlenecks or optimize processes.

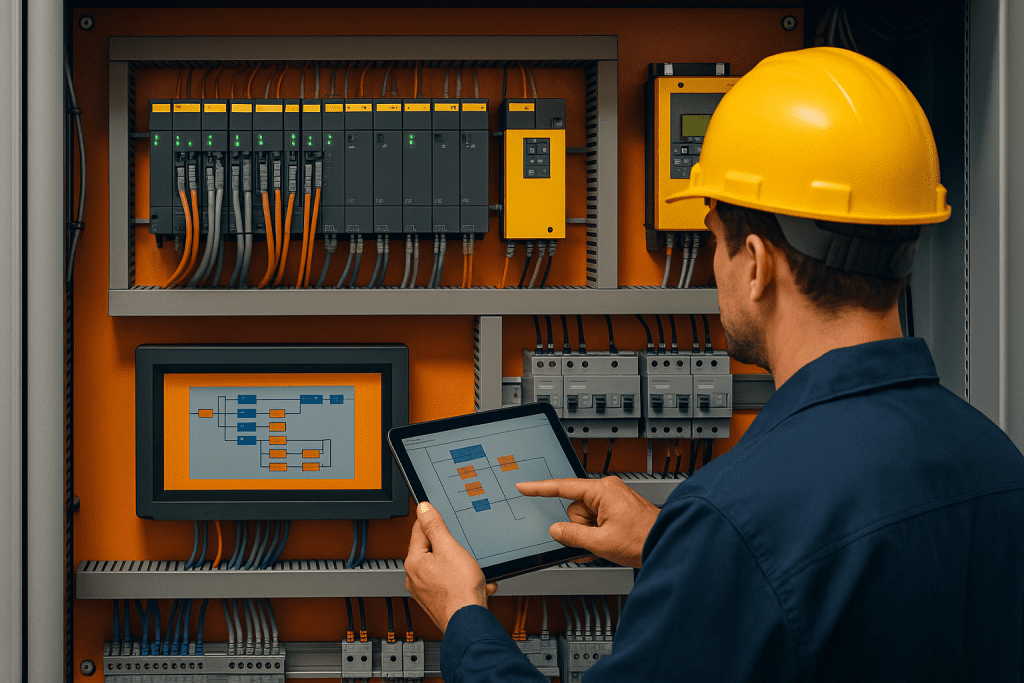

With modern SCADA designing and HMI touch displays, manufacturers can visualize every stage of production, track machine performance, and make data-driven decisions.

3. Energy Inefficiency

Traditional systems often run motors at full power, even when it’s not needed, leading to significant energy waste.

Upgrading with VFD programming and smart energy management solutions helps optimize motor speeds, minimize energy consumption, and cut electricity bills.

Example: Using VFDs instead of conventional starters can reduce energy usage by up to 30%, improving both sustainability and cost efficiency.

Benefits of Modern PLC Integration

1. Improved Reliability and Safety

Modern PLCs introduce advanced safety interlocks, emergency stop features, and intelligent error handling. This drastically reduces human error and prevents accidents on the factory floor.

2. Enhanced Productivity Through Automation

Integrating HMI and SCADA systems gives operators complete visibility and control over production lines.

From real-time dashboards to automated process adjustments, productivity increases without the need for extensive manual intervention.

3. Data-Driven Decision Making

With MIS Automation Software, factories can generate detailed production and downtime reports. This actionable data helps identify inefficiencies, streamline processes, and plan preventive maintenance effectively.

4. Energy Savings and Cost Efficiency

By combining modern PLCs with Energy Management Systems, manufacturers can monitor and optimize energy use across their facilities.

This not only reduces operational costs but also aligns with sustainability goals and government compliance standards.

Aknitech’s Proven Approach to Modern PLC Machine Upgrades

At Aknitech, we follow a structured, step-by-step process to ensure a smooth transition from outdated systems to modern automation setups.

Step 1: Initial Assessment and Audit

Our team conducts a comprehensive evaluation of existing machines, control panels, and wiring. We identify problem areas, inefficiencies, and potential risks to create a tailored upgrade plan.

Step 2: Designing the Upgrade Plan

Based on the assessment, we design a solution using cutting-edge PLC systems, network accessories, and HMI displays. The design is customized to fit the client’s specific needs and industry requirements.

Step 3: Installation and Integration

Our engineers retrofit new PLCs, VFDs, and control systems into the existing machinery, minimizing disruption to ongoing production.

Example: A recent upgrade for a manufacturing plant in Bhopal reduced downtime by 40% and delivered 25% energy savings within the first three months.

Step 4: Training and Handover

Once the upgrade is complete, we provide hands-on training to plant staff, ensuring they are confident in using the new systems effectively.

Our modern PLC machine upgrades help manufacturers achieve better energy efficiency and reduced downtime.

Why Choose Aknitech for Machine Restoration

- Expertise Across Industries: From textiles and food production to pharmaceuticals, we have extensive experience in diverse sectors.

- Local Presence in Bhopal: Rapid on-site support and personalized service for MP-based industries.

- Partnerships with Global Brands: Collaboration with AVEVA, Rexroth, Selec, and others to deliver world-class solutions.

- Proven Track Record: Successful legacy system upgrades with measurable improvements in efficiency and cost savings.

Future – Proof Your Machinery with Aknitech

Upgrading outdated machinery is not just about extending its life – it’s about future-proofing your production facility. By integrating modern PLCs, SCADA systems, and energy-efficient solutions, manufacturers can achieve higher productivity, lower costs, and improved reliability. Many industries in Bhopal rely on modern PLC machine upgrades to modernize their production systems.

At Aknitech, we combine technical expertise with a customer-first approach to deliver seamless legacy system upgrades.

Don’t let obsolete machines slow you down.

Contact Aknitech today to schedule a free consultation and take the first step toward smarter, more efficient industrial automation.