Modern factories cannot afford uncertainty. As industries move toward high-speed production, zero-downtime systems, and data-driven operations, one component has quietly become the backbone of every smart manufacturing line – Reliable PLC Panels used in advanced PLC electrical panel systems. Whether it’s a high-speed packaging unit, an automotive welding line, a wastewater treatment plant, or a material-handling system, the entire production cycle runs smoothly only when the PLC panel is reliable, secure and engineered correctly. In 2025, smart industries depend heavily on stable automation hardware because any weak link directly impacts output quality and plant efficiency.

What Is a PLC Panel?

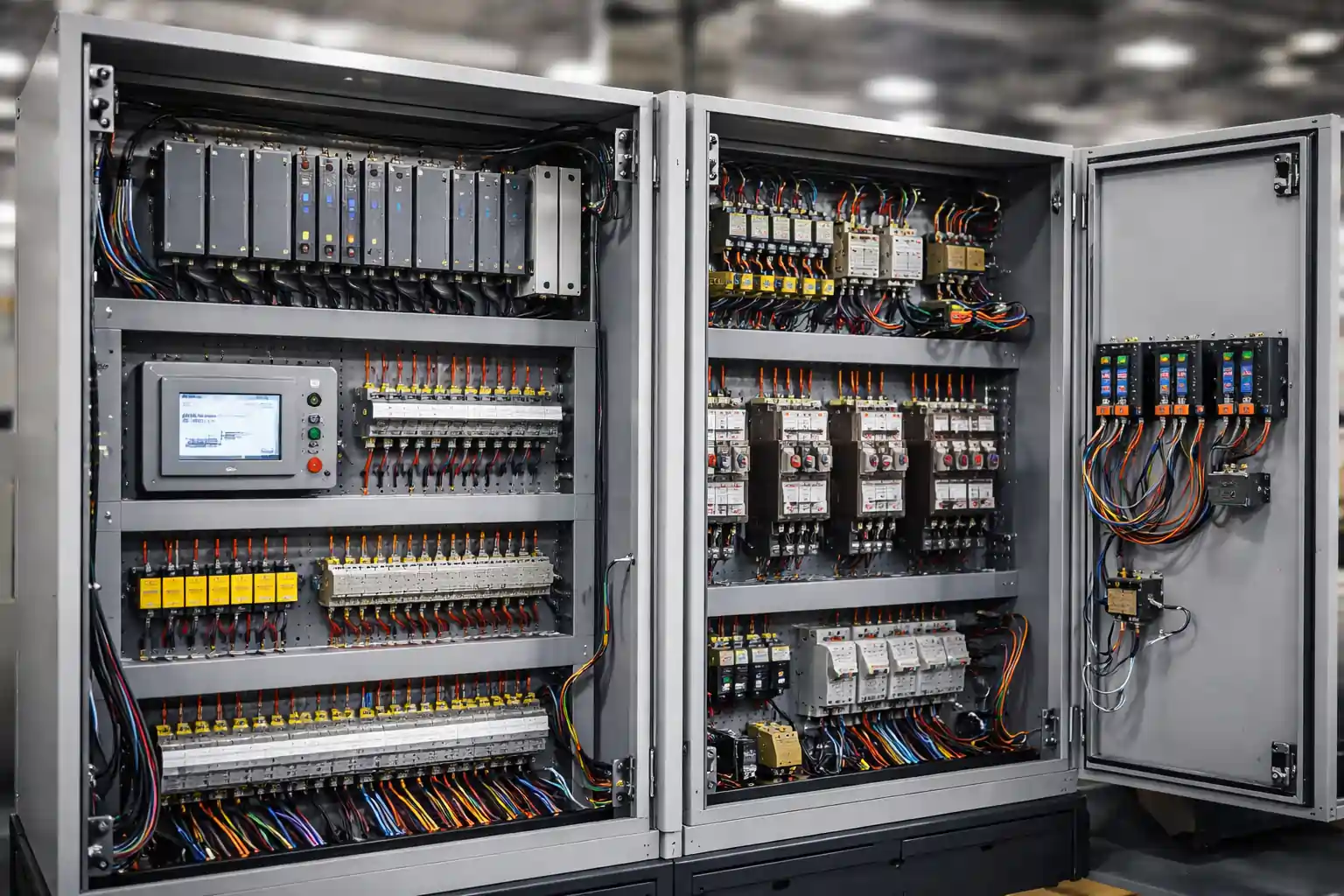

A PLC panel is an industrial control cabinet that houses the PLC controller, I/O modules, power supplies, relays, protection devices, circuit breakers, communication modules, and wiring. These plc control panel components work together to execute logic operations and control machine functions in real time. It functions as the “brain” of the automation system by continuously receiving signals from field sensors and actuators, executing programmed logic, and sending output commands to motors, valves, solenoids, and drives. If the PLC panel is designed poorly, wired incorrectly, or built with low-grade plc panel components, then even the best machinery will fail to perform consistently. Reliable PLC panels ensure accuracy, safety, and predictable machine response-making them essential for any modern production environment.

A well-designed PLC panel ensures:

- Accurate process sequencing

- Machine safety

- Consistent production quality

- Real-time fault reporting

- Smooth communication with HMI SCADA PLC, IoT and VFD systems

In simple terms: No PLC panel → No automated production.

Why Smart Factories Depend on Reliable PLC Panels

1. They Provide Real-Time Control Across the Entire Plant

Real-time control is the core requirement of any smart factory. A reliable PLC panel processes thousands of input and output signals per second, ensuring that motors start at the right time, valves open at the right angle, temperatures stay within limits, and cycle times remain consistent. This instant decision-making is only possible when the panel is equipped with high-quality industrial PLC hardware, proper wiring, and strong communication architecture. If the panel lags even for a moment, the entire production line experiences delays or inconsistent output.

A smart factory relies on real-time decision-making. PLC panels constantly monitor:

- Sensors

- Motors

- Pumps

- Valves

- Actuators

- Temperature/pressure/load conditions

Every millisecond matters – and only a stable PLC panel can process this data without failure. Smart factories depend on reliable PLC panels to maintain seamless operations without fluctuation or instability.

2. Reduced Downtime Through Instant Fault Detection

Unplanned downtime can cost factories lakhs of rupees every year. A reliable PLC panel helps prevent this by offering rapid fault detection and clear diagnostic feedback. When a motor overloads, a sensor disconnects, a valve jams, or a communication line fails, a well-designed PLC panel immediately identifies the issue and reports it to the operator. This is especially critical for modern plc manufacturers in india, who focus on building panels that reduce breakdown frequency.

In modern industries, even a 10-minute breakdown can cost thousands of rupees in:

- Wastage

- Delayed production

- Labor idle time

- Missed dispatch timelines

Reliable PLC panels detect:

- Overloads

- Communication failures

- Sensor faults

- Motor failures

- Safety interlock issues

This allows technicians to resolve problems before they escalate into full production stoppages. Fault logs, interlocks, and safety relays integrated within the panel further reduce downtime and ensure that machines return to operation quickly and safely.

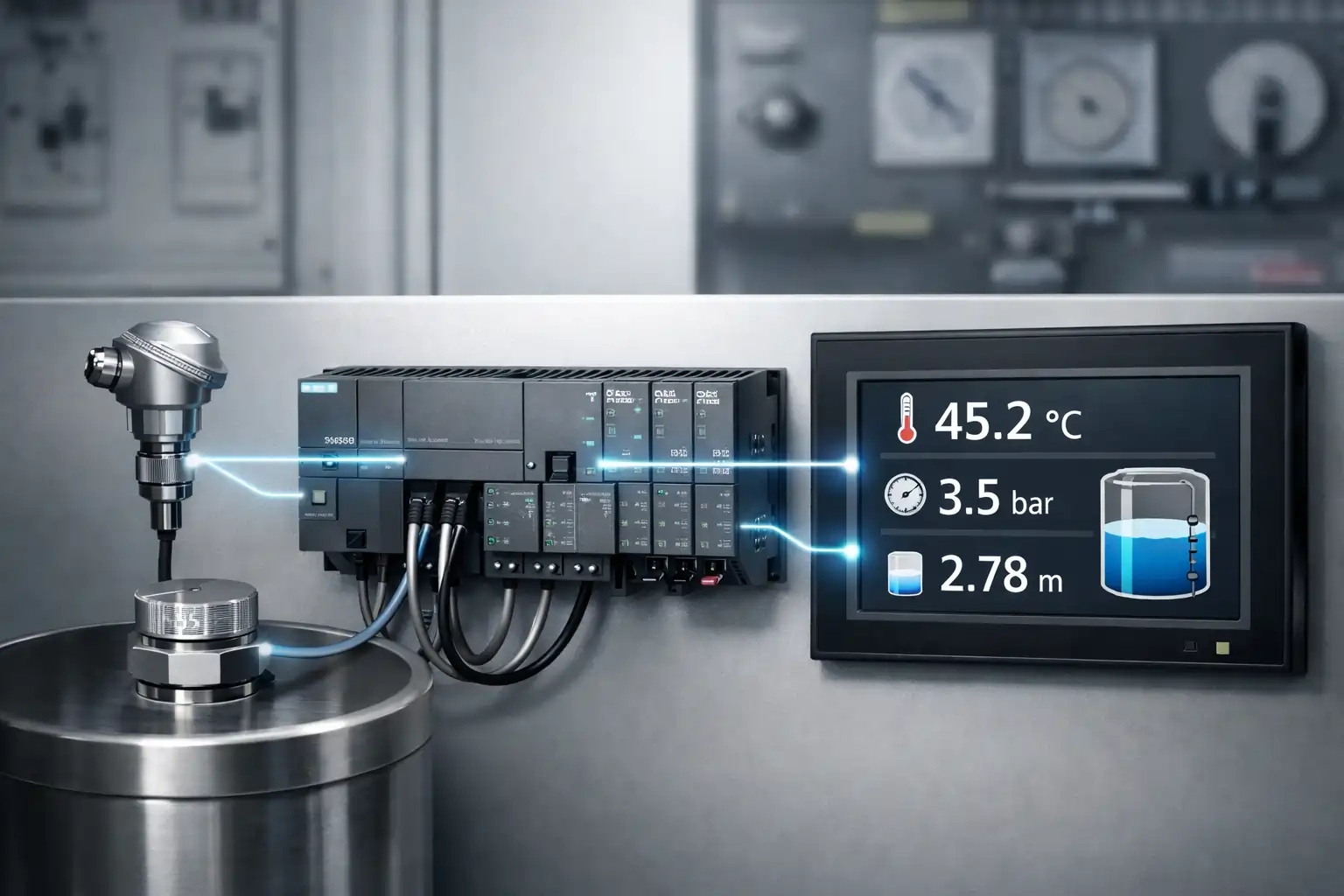

3. Seamless Integration With SCADA, HMI and IoT

Smart factories depend heavily on system connectivity. A good PLC panel integrates smoothly with SCADA dashboards, HMI touch panels, VFD drives, and IoT devices using industrial protocols like Modbus, Profinet, EtherNet/IP, Profibus, or CAN. This deep connection between SCADA software, PLC, and IoT layers ensures a unified automation environment.

A reliable PLC panel supports:

- SCADA for plant monitoring

- HMI for operator controls

- VFDs for motor energy optimization

- IoT gateways for cloud analytics

- Industrial protocols (Modbus, Profinet, EtherNet/IP, CAN, Profibus)

Poor integration = chaotic production.

Stable PLC panels = real-time data + predictive analytics + smoother operations.

When the PLC panel is unstable, the entire communication network suffers-causing delayed feedback, inaccurate readings, and operator confusion. This is why smart factories require robust PLC panels that support stable, high-speed data exchange and modern scada protocols in iot for long-term operational efficiency.

4. Higher Production Accuracy and Consistent Quality

Modern factories cannot rely on manual adjustments or guesswork. They require precise batch control, consistent cycle timing, accurate temperature regulation, and stable motor speeds. A reliable PLC panel ensures all these parameters remain within the required range, reducing errors, rework, and material wastage. Every logic step-from machine start-up to shutdown-is executed consistently using advanced programming tools and stable plc brands.

PLC panels help control:

- Fill levels

- Machine speeds

- Temperature profiles

- Cutting precision

- Pressure curves

- Batch sequences

A weak panel can cause inconsistent batches, rejection, customer complaints, and raw material loss. Industries like food processing, pharmaceuticals, or packaging depend strongly on stable iot control panel integration to maintain uniform quality throughout production.

5. Essential for Safety and Compliance

Smart factories operate under strict safety standards. Emergency stops, overload protections, interlocks, and fail-safe mechanisms must respond correctly every single time. A reliable PLC panel follows safety logic without delay and ensures hazardous conditions are handled immediately. Poor-quality or outdated panels may fail to respond in time, putting workers, machinery, and products at risk.

Factories must comply with:

- Safety interlocks

- Emergency shutoff logic

- Overload protections

- Fire and hazard protocols

Reliable PLC panels ensure every safety condition is executed correctly.

This protects:

- Workers

- Machinery

- Inventory

- Electrical systems

Smart factories depend heavily on PLC panels that maintain compliance with industrial safety norms while supporting enhanced visibility through SCADA IoT integrations.

6. Easy Upgrades and Future Scalability

Factories evolve constantly-new machines are added, production lines expand, and advanced digital tools become necessary. A well-designed PLC panel allows easy integration of new I/O modules, communication cards, sensors, drives, and SCADA functions. It supports future Industry 4.0 upgrades such as predictive maintenance, cloud connectivity, and smart energy monitoring.

A well-engineered PLC panel allows:

- Adding new I/O modules

- Integrating new sensors

- Connecting advanced SCADA dashboards

- Remote monitoring

- Predictive maintenance

Cheap or outdated panels limit scalability – and block Industry 4.0 adoption. Stable PLC panels also help integrate advanced vfd programming, making motor control more energy-efficient and adaptable. Smart factories choose reliable PLC panels because they support long-term growth without redesigning entire control systems.

Industries That Benefit the Most from Reliable PLC Panels

Reliable PLC panels are used in multiple sectors including manufacturing, food and beverage, chemicals, textiles, OEM machinery, packaging, water treatment, utilities, steel, mining, and material handling. Industries where continuous operation is critical rely on robust automation hardware to maintain production output with accuracy and speed.

- Manufacturing & assembly lines

- Food & beverage plants

- Textile & process industries

- Packaging & material handling

- Water & wastewater treatment

- Cement, steel & mining

- Chemical & pharma industries

Wherever continuous production is required, PLC panels are non-negotiable.

Common Problems Caused by Weak or Poorly Designed PLC Panels

Factories using low-quality PLC panels often face irregular machine behavior, unstable outputs, communication dropouts, slow cycle times, and frequent breakdowns. These issues make automation unreliable and directly reduce production efficiency.

Factories using low-quality or poorly programmed panels face:

- Frequent breakdowns

- Unstable machine behavior

- Communication failures

- Slow cycle times

- Poor energy usage

- Inaccurate outputs

- Unsafe conditions

Most “production pain points” are directly linked to weak PLC panel design.

How to Choose the Right PLC Panel

1. Sufficient I/O Capacity

The PLC panel should have enough input and output points to handle all sensors, switches, motors, and future add-ons. Adequate I/O ensures the industrial PLC system can grow without redesign.

2. Expandability for Future Use

A smart factory keeps upgrading. The PLC panel must support additional modules, cards, and components without needing a full replacement.

3. Support for Industrial Protocols

The panel should communicate with other devices using protocols like MODBUS, PROFINET, and Ethernet IP. This is essential for SCADA IoT connectivity.

4. Compatibility with SCADA/HMI

Modern production lines require real-time monitoring. Your PLC panel must connect easily with SCADA software and HMI control screens.

5. Quality Components & Wiring

A reliable panel uses branded PLC units, premium wiring, ferrules, ducts, earthing, and strong termination quality.

6. Built-In Safety & Surge Protection

The panel should include MCBs, fuses, relays, E-stop wiring, and surge protection to protect both machines and operators.

7. Clear Panel Layout & Documentation

A professional panel has labelled terminals, wiring diagrams, and manuals-making troubleshooting easier.

8. Easy Maintainability

Components must be arranged logically so technicians can access or replace them without complications.

Why AKNItech Is Trusted for Reliable PLC Panels

AKNItech specializes in designing industrial-grade PLC panels using high-quality components, clean wiring, neat panel layouts, and well-optimized logic. The team works with leading plc brands like Siemens, Mitsubishi, Delta, Allen-Bradley, and Omron, ensuring full compatibility with any industrial setup.

Modern factories need a partner who understands:

- Industrial processes

- Electrical engineering

- Automation logic

- SCADA integration

- Safety standards

- On-site troubleshooting

AKNItech delivers:

- Custom PLC panels for any industrial application

- High-quality components (Siemens, Delta, Mitsubishi, Allen-Bradley)

- Neat wiring, proper labeling, and safety protections

- Optimized PLC programs for fast and stable control

- Integration with SCADA/HMI/VFD/IoT systems

- On-site commissioning & long-term support

AKNItech panels are built for stability, fast communication, accurate sequencing, safety compliance, and future scalability.

Moving Forward With Smarter Automation

Smart factories depend on reliable PLC panels because they provide real-time control, higher accuracy, faster fault detection, safe operations, and seamless connectivity with SCADA, HMI, IoT, and vfd programming systems. As Indian industries continue upgrading to Industry 4.0, the importance of stable PLC panels has grown significantly. Investing in a high-quality PLC panel is not just a technical decision-it is a long-term commitment to better productivity, improved safety, and continuous growth.