In 2025, the demand for skilled automation specialists is higher than ever. From construction to manufacturing and utilities, PLC programming has become a core part of modern automation systems. Whether you’re an engineering student or a professional aiming to upskill or move into plant management, learning PLCs gives you the foundation for a rewarding career in automation.

Why PLC Programming Still Matters in 2025

Programmable Logic Controllers (PLCs) are the primary components for automated system. They supervise the processes, machinery and systems in every industrial building and range all the way from MCC panels found in Bhopal to gigantic production facilities across India.

Even though the latest technologies, like management of an IoT device as well as artificial intelligence-powered diagnostics are taking off, PLCs remain crucial to offer continuous, reliable control.

Where to Start: A Beginner-Friendly Path

The most effective starting point is crucial. This is a straightforward guideline that describes the essential components of HTML0:

| Stage | What to Focus On | Recommended Tools/Skills |

| 1. Understand Basics | What exactly are PLCs? What do they actually do? | Siemens S7, Allen-Bradley intro videos |

| 2. Learn Ladder Logic | The logic that is the foundation of PLC programming | Ladder diagrams, online simulators |

| 3. Practice Simulation | Examine your skills of thinking with virtual PLCs | PLCLogix, EasyPLC, Factory I/O |

| 4. Use Real Hardware | Connect to output and input modules. | Tests in the lab, hands-on sessions |

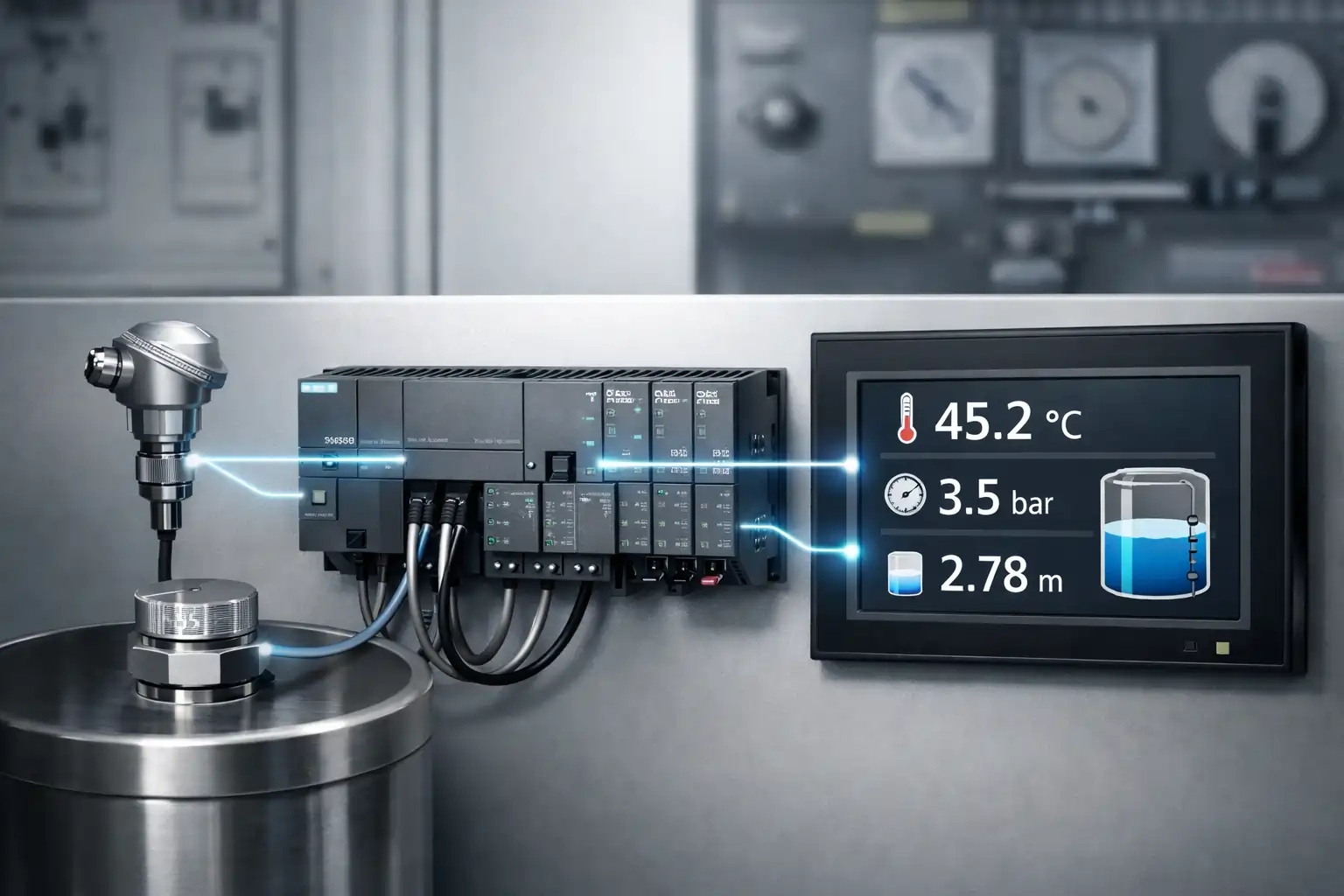

| 5. Learn Communication | Learn Modbus, Ethernet, HMI Links | SCADA & HMI basics the fundamental principles of data transmission |

| 6. Apply in Projects | Case studies based on actual life experiences, and troubleshooting | Home automation, motor control, MIS panels |

What to Avoid When Learning PLC Programming

In 2025, lots of students could be at risk of falling into traps that they’ve been avoiding for long periods of time. Here’s what you need to look for:

1. Jumping to Advanced Tools Too Early

Making use of SCADA, IoT protocols, or advanced VFD programs without an understanding of basic concepts like ladder logic generally leads to confusion.

2. Ignoring Hardware

Simulators are useful, but they are not always a good idea. Not paying attention to the real challenges associated with input and output could lead to a lack of information, particularly for those who deal on electrical panels for Field equipment and PLCs.

3. Not Learning Industry Standards

Each plant or factory may utilize a different version of the PLC. You may not have a clue about how to work with Allen-Bradley, Siemens and Delta’s PLCs. could limit your options to work.

4. Relying Only on Theory

The knowledge gained from projects like maintenance of old equipment as well as motor control panels is much better than the data that you find in a book.

Aknitech’s Role in Industrial Skill Development

The headquarters of the company is located at Bhopal, Aknitech Solutions does not only develop innovative PLC panels SCADA technologies and systems based on IoT for controlling and monitoring, but is also a key participant in the education of the next generation of talent.

They can help you with:

- PLC SCADA training near me is possible because of personal training in person

- Live demonstrations that incorporate various HMI screens and VFD starters. HMI screens, and automation panels to the MIS.

- Examples that could be used at work, such as instances of the PT100 chart integration, SCADA dashboards and the configuration of sensors to IoT

Skills That Matter Most in 2025

Here are some that are among the most highly-rated capabilities and terms that you must be aware of if there is a serious intention to automate

- PLC Programming (Ladder Logic, Structured Text)

- SCADA & HMI Designing

- IoT Device Management Protocols

- VFD / Soft Starter Programming

- MIS Panel Design & Implementation

- Network Accessories & Communication

- Troubleshooting old PLCs

- Sensors are able to be linked (like PT100 RTD)

Smart Learning, Smart Future

The best way for mastering PLC Programming in 2025 doesn’t only mean you’ve mastered the fundamentals of programming, it’s about knowing what industrial systems of today work and how devices communicate with each other, and then applying that knowledge to automating the actual applications.

Whatever your goals are, whether it’s the creation of the Internet of Things-connected Control Panel to Bhopal and directing your IoT-enabled SCADA applications.The initial step involves to know the basics of PLCs.

Guidelines: Don’t just learn about PLCs. Be aware of the capabilities they have to connect to, and manage the entire industrial automation.

Do you require assistance in determining the best method to begin your journey with PLC?

Check out Aknitech to get in touch to experts that are building the automation landscape in India.