PT100 RTD sensors are essential in modern industrial automation, where precision and reliability drive every process. Whether it’s a power plant, chemical factory, or food-processing unit, accurate temperature monitoring ensures safety, quality, and efficiency.

Why PT100 RTD Matters in Modern Industries

In the world of industrial automation, precision is everything. Whether it’s a power plant, chemical factory, or food-processing unit, accurate temperature monitoring ensures safety, quality, and efficiency.

One of the most reliable temperature sensors used today is the PT100 RTD – short for Platinum Resistance Temperature Detector. It measures temperature by detecting changes in electrical resistance of platinum, one of the most stable metals for thermal sensing.

At 0 °C, a PT100 sensor has exactly 100 ohms resistance – and this value increases linearly with temperature. Because of this stability, PT100 RTDs are trusted across industries where even a small temperature variation can affect product quality or system safety.

How PT100 RTD Sensors Work

RTDs follow a simple principle: as temperature rises, metal resistance increases.

The PT100 sensor converts that resistance change into an electrical signal, which is interpreted by PLCs, SCADA systems, or IoT controllers. These systems then display or regulate temperature automatically.

Key Characteristics of PT100 RTDs:

- Highly accurate (±0.1 °C typical)

- Excellent repeatability and long-term stability

- Suitable for harsh or high-vibration environments

- Compatible with industrial PLC control panels and IoT monitoring devices

- Linear output simplifies signal processing

This combination of accuracy, stability, and integration makes PT100 RTDs the gold standard in industrial temperature measurement.

Standard PT100 RTD Temperature Chart (°C vs Resistance Ω)

| Temperature (°C) | Resistance (Ω) |

| -50 | 80.31 |

| -25 | 90.19 |

| 0 | 100 |

| 25 | 109.73 |

| 50 | 119.4 |

| 75 | 129.03 |

| 100 | 138.5 |

| 150 | 157.32 |

| 200 | 175.86 |

| 250 | 194.1 |

| 300 | 212.05 |

| 350 | 229.72 |

| 400 | 247.09 |

These values are standardized under IEC 60751 and are widely used for calibration and automation processes.

PT100 RTD vs Thermocouple – A Practical Comparisonv

| Feature | PT100 RTD | Thermocouple |

| Accuracy | Very high (±0.1 °C) | Moderate (±1 °C) |

| Temperature Range | -200 °C to +600 °C | -200 °C to +1200 °C |

| Response Time | Medium | Fast |

| Signal Type | Resistance | Voltage |

| Stability | Excellent | Prone to drift |

| Cost | Slightly higher | Lower |

| Best Used For | Precision control, PLC/SCADA/IoT systems | High-temperature processes (furnaces) |

If your process demands accuracy, repeatability, and digital integration – choose PT100 RTD. It connects seamlessly with industrial automation setups like those developed by AKNITech.

Industrial Applications of PT100 RTD Sensors

1. Manufacturing & Process Automation

Used for temperature regulation in plastic molding, packaging, and assembly lines. With PLC panels and SCADA in IoT, real-time data ensures consistent production quality.

2. Power & Energy

PT100 sensors monitor turbine bearings, generator coils, and transformer oils. They prevent overheating and maintain stable operations in power plants.

3. Chemical & Pharmaceutical

Precision is vital in chemical reactions and medicine production. PT100 RTDs deliver accurate readings to maintain safe reaction conditions.

4. Food & Beverage

Used in pasteurization, brewing, and cold storage. PT100 sensors ensure every batch meets hygiene and quality standards.

5. HVAC & Building Automation

Essential for maintaining comfort and energy efficiency in smart buildings. Integrated with IoT device management systems, they enable remote control and monitoring.

6. Smart Irrigation & Agriculture

When connected via IoT devices such as Raspberry Pi or microcontrollers, PT100 sensors help maintain optimal soil and water temperatures – an innovation already explored by AKNITech’s smart irrigation systems.

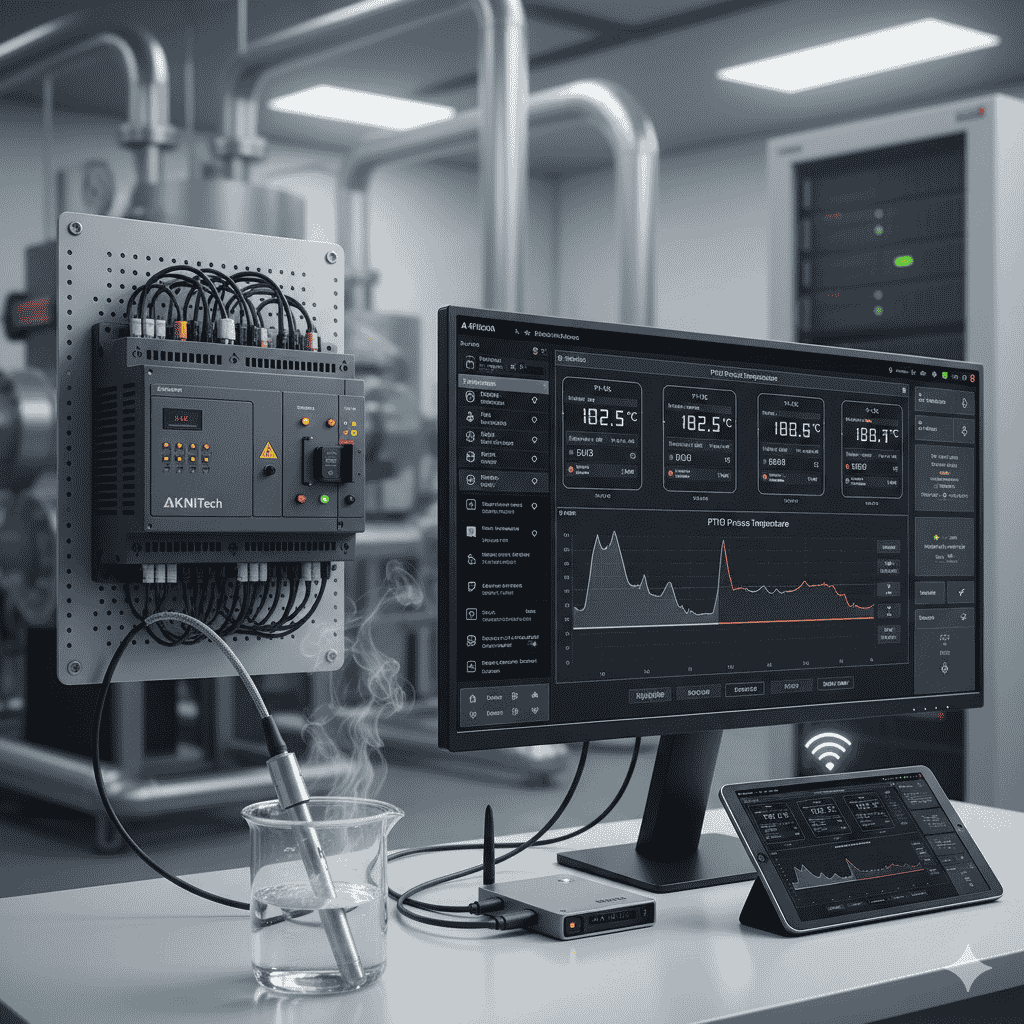

Integration with PLC, SCADA, and IoT Systems

Today’s industries run on data. PT100 RTD sensors serve as the first link in that data chain.

When connected to a PLC control panel, the sensor’s analog signal is converted into digital data and sent to a SCADA dashboard. Operators can then visualize, control, and record the temperature in real time.

With the rise of Industrial IoT, AKNITech integrates PT100s into intelligent networks using secure IoT device management protocols (like MQTT or CoAP). This allows:

- Remote configuration and monitoring

- Predictive maintenance alerts

- Cloud-based data analytics

- Integration with mobile dashboards

Such systems help engineers monitor critical assets from anywhere, improving uptime and efficiency.

Advantages of Using PT100 RTD Charts

- Simplifies calibration and system verification

- Enhances product quality through precise control

- Detects deviations early to prevent breakdowns

- Improves predictive maintenance scheduling

- Provides consistent accuracy for years

- Complies with international standards (IEC 60751)

Understanding PT100 Classes – A vs B

| Class | Accuracy at 0 °C | Tolerance Range (°C) | Typical Use |

| Class A | ±0.15 °C | -100 to +450 °C | Precision industrial processes |

| Class B | ±0.30 °C | -200 to +600 °C | General automation applications |

Selecting the right class depends on process tolerance and cost. Most control panels and IoT systems favor Class A for superior precision.

PT100 RTD in IoT Device Management

With Industry 4.0 gaining speed, IoT device management plays a vital role in automation. PT100 sensors act as data inputs to IoT gateways (e.g., Raspberry Pi IoT setups) which handle configuration, connectivity, and security.

Through IoT system management, engineers can:

- Track temperature trends remotely

- Set alarms or shutdowns when limits exceed

- Control processes automatically

AKNITech’s IoT and SCADA solutions merge these functions into a single, easy-to-use platform – turning factories into smart, connected ecosystems.

Frequently Asked Questions (FAQ)

Q1. What does PT100 mean?

“PT” stands for Platinum, and “100” indicates 100 Ω resistance at 0 °C.

Q2. How accurate are PT100 RTDs?

Depending on class, accuracy ranges from ±0.1 °C (Class A) to ±0.3 °C (Class B).

Q3. Can PT100 sensors connect directly to a PLC?

Yes. They connect via analog input modules or transmitters, enabling integration with SCADA and IoT systems.

Q4. What’s the difference between PT100 and PT1000?

PT1000 offers higher sensitivity (1000 Ω at 0 °C) and better noise immunity for short cable runs.

Q5. Where are PT100 RTDs used most?

In manufacturing, energy, HVAC, and automation where temperature accuracy drives performance.

Why PT100 RTD Sensors Matter in Modern Industry

The PT100 RTD Sensors chart is more than a reference table – it’s the foundation of precision temperature measurement in today’s connected industries.

When paired with PLC panels, SCADA interfaces, and IoT monitoring devices, PT100 sensors empower industries to achieve real-time control, energy efficiency, and long-term reliability.

If you’re looking to integrate PT100 RTD Sensors or upgrade your automation with IoT & SCADA systems, connect with the experts at AKNITech. We design smart, reliable control solutions that keep your operations running efficiently.