Industrial automation is evolving fast, and IoT and SCADA integration is now at its core. Across India’s manufacturing, power, and infrastructure sectors, AKNITech helps factories adopt smart automation to increase efficiency and reduce costs.

While major global players like Siemens India, ABB, and Rockwell Automation dominate the high-end market, innovative Indian firms like AKNITech are leading the next wave of custom, localized, and affordable automation built for Indian industries.

From IoT device management to PLC control panels and SCADA integration, AKNITech is building a future-ready foundation for smarter, connected factories.

1. A Vision Rooted in Innovation and Reliability

AKNITech stands apart with its vision to bridge industrial engineering with intelligent automation.

Our mission: to make automation simpler, smarter, and more sustainable for every Indian business.

We design automation systems that learn, adapt, and evolve – making us more than just an equipment provider.

Our guiding principles:

Efficiency – Maximize productivity with real-time visibility.

Reliability – Ensure uninterrupted operations and secure data flow.

Scalability – Upgrade easily as industries grow or diversify.

This approach places AKNITech among India’s emerging leaders in industrial automation, rivaling the innovation standards of Schneider Electric and L&T Electrical & Automation, with the agility of a dedicated local team.

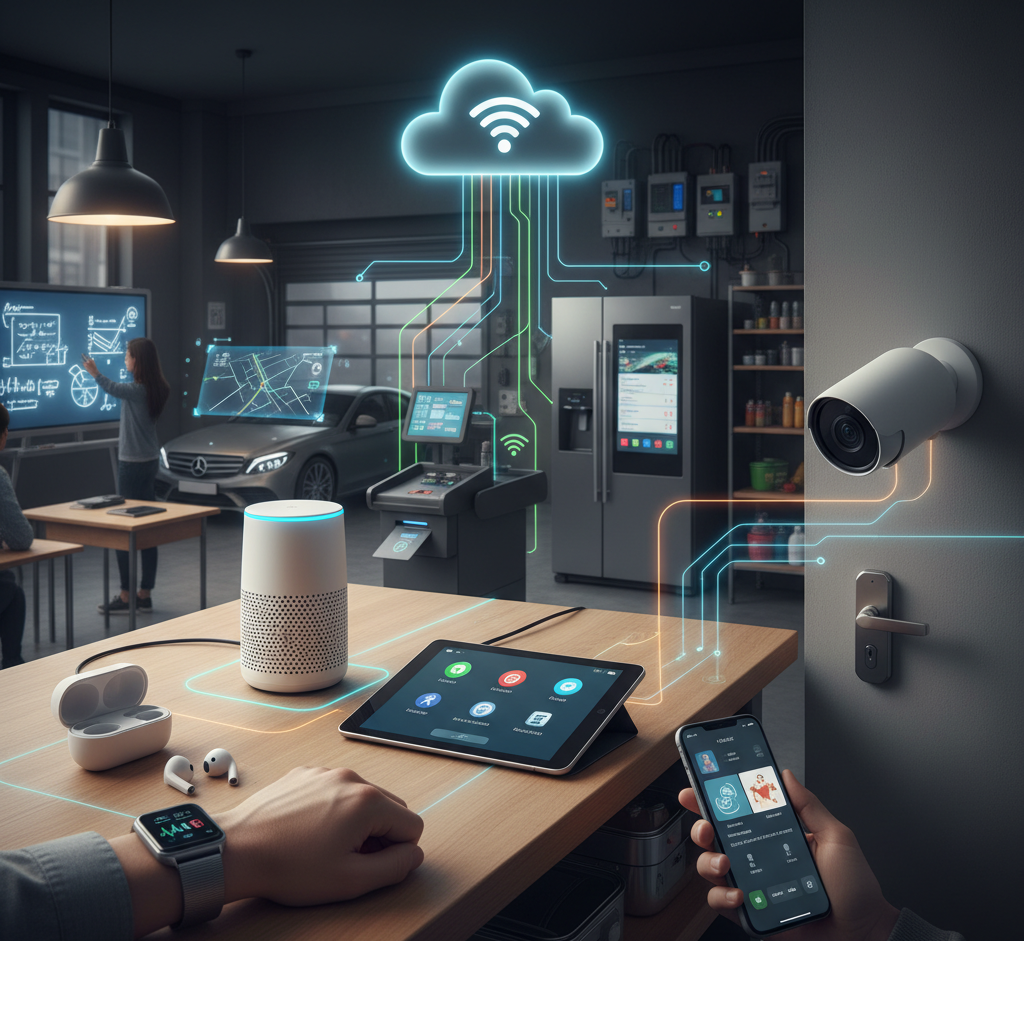

2. IoT and SCADA Integration: Smart Technology That Connects Everything

At AKNITech, every machine, sensor, and controller can “talk” through IoT.

Our IoT Device Management Platforms integrate Raspberry Pi, SCADA, and PLC systems into a single dashboard.

This connected ecosystem allows industries to:

- Monitor all devices remotely.

- Analyze energy and productivity data.

- Predict failures using IoT analytics.

- Manage configurations securely with MQTT & CoAP protocols.

By combining IoT and SCADA in industrial automation, we help Indian factories achieve Industry 4.0 readiness – a benchmark once reserved for multinationals.

IoT and SCADA Integration Comparison: AKNITech vs Global Automation Leaders

| Feature | AKNITech (India) | Siemens / ABB / Schneider Electric |

| Customization | Fully customizable for Indian industrial needs | Standardized global modules |

| Local Support | On-site engineering support within 24 hrs | Limited India-based deployment teams |

| Cost Efficiency | 30–40% lower system cost | Premium global pricing |

| Technology Integration | IoT, PLC, SCADA, EMS, MIS all unified | Individual systems offered separately |

| Response Time | Real-time remote & physical support | Slower due to regional coverage limits |

| Design Flexibility | Adaptable for small and mid-size industries | Primarily designed for large enterprises |

While global brands lead in volume, AKNITech excels in personalization, affordability, and rapid support – the three pillars Indian industries truly value.

3. MIS Automation: Data That Drives Decisions

Data is the heart of every industrial system.

AKNITech’s MIS Automation Software transforms raw operational data into clear, actionable insights.

Features include:

- Real-time dashboard visualization.

- Integration with PLC & SCADA systems.

- Automated report generation.

- Cloud-based accessibility.

Factories across Bhopal, Indore, and Nagpur use AKNITech’s MIS systems to analyze performance, reduce manual reporting, and improve operational accuracy – a level of digital maturity once found only in companies like Tata Power and JSW Steel.

4. Advanced Control Systems: The Core of Automation

Every smart system begins with a reliable PLC Control Panel.

AKNITech’s panels are designed for accuracy, safety, and durability, integrating hardware from trusted brands such as BELNO, Rexroth, Selec, and AVEVA.

We manufacture:

- PLC Electrical Panels

- VFD Panels

- Power Control Centre Panels (PCC)

- Automation Panels with SCADA

Each unit undergoes precision testing to ensure it meets global safety and performance standards.

| Comparison: Traditional Automation vs Smart Automation | ||

| Parameter | Traditional Automation | Smart Automation (AKNITech) |

| Monitoring | Manual supervision | Real-time IoT-based dashboards |

| Maintenance | Reactive (after failure) | Predictive (alerts before downtime) |

| Control | Local-only PLC systems | Cloud-connected SCADA + IoT |

| Energy Use | High power consumption | Optimized via Energy Management System |

| Reporting | Paper logs or Excel sheets | Automatic, visual MIS reports |

| Scalability | Complex and expensive | Modular & easily expandable |

Smart automation solutions provide measurable gains in efficiency, energy management, and cost control – and AKNITech is enabling this shift for Indian manufacturers.

5. Energy Management: Smarter Power for Smarter Growth

Rising energy costs demand smarter resource management.

AKNITech’s Energy Management System (EMS) integrates with PLCs and IoT sensors to monitor power usage in real time.

Benefits:

- Reduce wastage and inefficiency.

- Detect anomalies early.

- Cut electricity bills by 10–20%.

- Achieve sustainability compliance.

These systems align AKNITech with forward-thinking innovators like Delta Electronics and Honeywell India, while maintaining flexibility and affordability.

6. Local Expertise, Global Standards

AKNITech’s engineering team brings global expertise with local insight.

We understand India’s infrastructure, industrial challenges, and power constraints better than any offshore integrator.

Advantages of working with a PLC manufacturing company in Bhopal like AKNITech:

- Faster delivery and on-site service.

- Lower setup costs.

- Tailored design for local industries.

- End-to-end system integration and maintenance.

7. Staying Ahead with Global Automation Trends

The automation industry is evolving rapidly with AI, ML, and edge computing reshaping the landscape.

AKNITech keeps pace by adopting:

- AI-powered analytics for predictive maintenance.

- Edge IoT devices for instant decision-making.

- Cloud-based SCADA for remote supervision.

- Cybersecurity integration for industrial data protection.

These trends are steering the world toward Industry 5.0, and AKNITech is already preparing Indian industries for that future.

8. Continuous Support: Beyond Installation

AKNITech doesn’t just install systems – we maintain partnerships.

Our clients receive:

- Lifetime remote support.

- Regular system audits.

- Training for in-house engineers.

- Ongoing software upgrades.

This client-first model builds long-term trust – the kind global giants can’t replicate at a regional scale.

Frequently Asked Questions (FAQs)

1. What makes AKNITech different from Siemens, ABB, or Schneider Electric?

AKNITech stands out by offering locally customized industrial automation solutions designed for Indian industries. While global brands focus on standardized systems, AKNITech provides cost-effective, flexible, and scalable solutions with 24-hour on-site support and faster deployment across India.

2. Does AKNITech provide end-to-end industrial automation services?

Yes. AKNITech offers complete automation solutions – from PLC and SCADA integration to IoT-based monitoring, Energy Management Systems (EMS), and MIS Automation Software – ensuring real-time control, data-driven decision-making, and seamless connectivity across all factory operations.

3. How does AKNITech support Industry 4.0 and 5.0 transformation?

AKNITech integrates IoT, AI analytics, and edge computing to make factories smarter and more predictive. Its smart automation systems enable data visualization, predictive maintenance, and energy optimization -essential pillars of Industry 4.0 and future-ready Industry 5.0 standards.

4. Which industries benefit the most from AKNITech’s automation systems?

AKNITech serves a wide range of industries including manufacturing, power distribution, water treatment, infrastructure, and process industries. Its localized approach ensures systems are adapted to Indian working conditions, environmental factors, and operational needs.

5. Does AKNITech provide post-installation support and maintenance?

Absolutely. AKNITech believes in long-term partnerships. Clients receive lifetime remote support, regular performance audits, training for in-house engineers, and software upgrades to ensure their automation systems stay efficient and future-ready.

AKNITech Leading India’s IoT and SCADA Integration Era

In an industry led by names like Siemens, ABB, and Schneider, AKNITech has created its own niche – offering smart automation solutions that combine world-class engineering with local affordability and agility.

From IoT and SCADA integration to PLC panel manufacturing and Energy Management Systems, AKNITech delivers the complete automation ecosystem.

Our mission is simple:

To make Indian industries smarter, more connected, and globally competitive.