India’s manufacturing landscape is undergoing a massive transformation powered by industrial IoT and SCADA technologies.

As industries move toward Industry 4.0, systems like IoT (Internet of Things) and SCADA (Supervisory Control and Data Acquisition) are reshaping how factories monitor, control, and optimize their operations.

From automotive to steel and energy sectors, industrial IoT and SCADA are no longer optional tools – they’ve become the foundation of intelligent manufacturing.

At the center of this movement stands AKNITech, a Bhopal-based automation and control solutions provider, helping Indian industries embrace data-driven, connected, and sustainable systems.

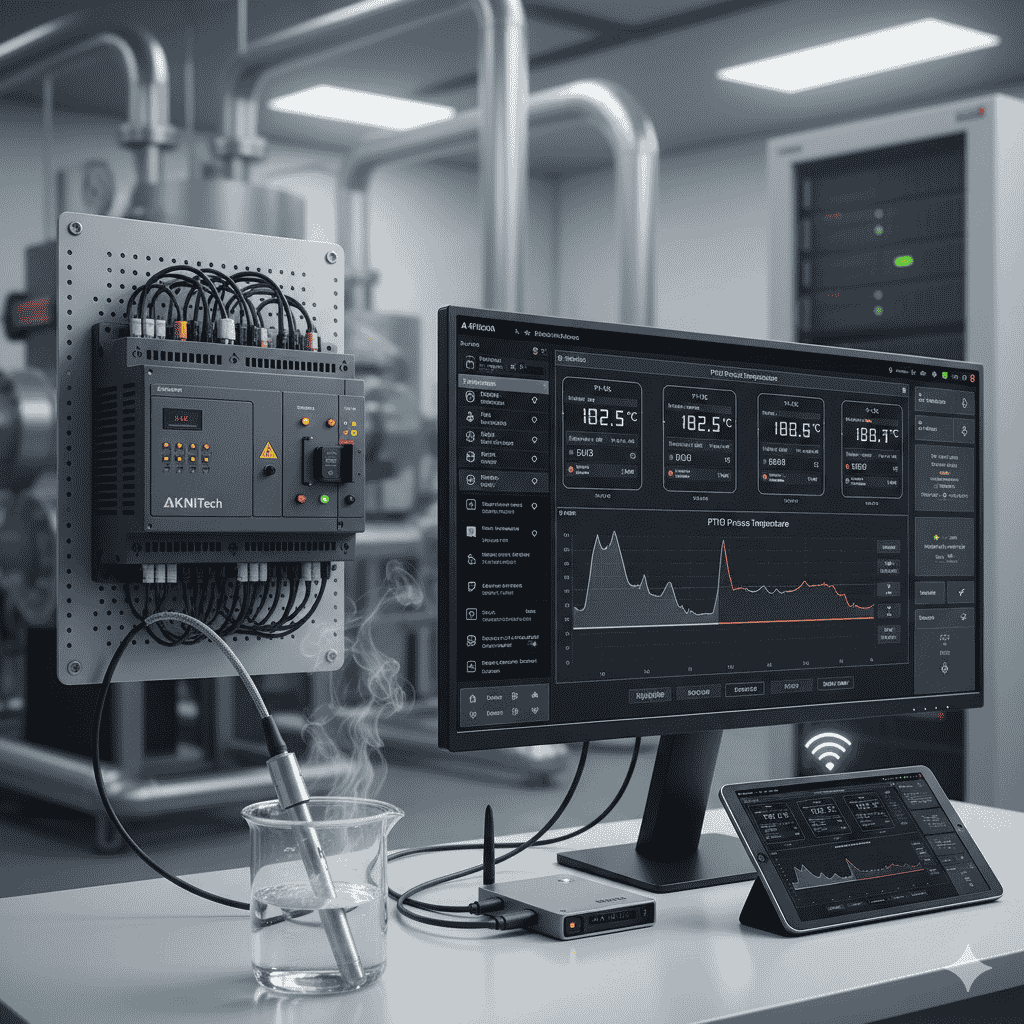

1. Industrial IoT and SCADA bring together connected sensors and centralized control to revolutionize modern manufacturing.

Before diving into AKNITech’s role, let’s simplify the concept.

- IoT in Manufacturing: Involves connecting machines, sensors, and controllers to collect real-time data for smarter decisions.

- SCADA Systems: Allow centralized monitoring and control of industrial processes using HMI dashboards and data acquisition networks.

When combined, IoT and SCADA integration creates a digital ecosystem where every machine “talks,” every fault is detected instantly, and every process is optimized in real time.

2. Why IoT-SCADA Integration Is a Game Changer for India

India’s industrial growth is accelerating, but challenges remain – outdated equipment, manual supervision, and inconsistent production data.

By integrating IoT device management with SCADA automation, factories achieve:

Real-time visibility: Monitor every line and sensor remotely.

Predictive maintenance: Detect issues before they cause breakdowns.

Energy optimization: Use power more efficiently.

Data intelligence: Make informed production decisions.

This integration bridges the gap between hardware and cloud analytics, enabling factories in India to compete globally on performance and efficiency.

3. AKNITech leads India’s journey toward industrial IoT and SCADA, delivering tailored solutions for smart, connected manufacturing.

While global automation giants like Siemens India, ABB, and Rockwell Automation serve large enterprises, many Indian manufacturers need localized, adaptable, and affordable solutions.

That’s where AKNITech steps in.

Founded with the mission to make smart automation accessible to every Indian industry, AKNITech delivers custom-built IoT and SCADA systems that fit the unique operational requirements of local manufacturing units.

From PLC panel design to real-time SCADA dashboards, every solution AKNITech builds is engineered to bring global technology down to the shop floor – efficiently and cost-effectively.

4. How AKNITech Implements IoT and SCADA Integration

AKNITech’s approach to industrial IoT and SCADA is not “plug-and-play” – it’s a stepwise engineering process designed for reliability and scalability.

Step 1: Data Collection Layer

- Installation of IoT sensors, PLC modules, and smart meters.

- Real-time data acquisition through MQTT, CoAP, and Modbus protocols.

Step 2: SCADA Integration Layer

- Configuration of HMI and SCADA software (AVEVA, Wonderware, etc.)

- Visualization of operational data through user-friendly dashboards.

Step 3: Analytics & Monitoring

- Integration with MIS Panels and Energy Management Systems.

- Automated alerts and reporting for key performance indicators.

Step 4: Cloud Connectivity

- Remote monitoring via mobile or web dashboards.

- Secure cloud data storage for long-term analysis and insights.

This holistic framework ensures industries can monitor performance, manage energy, and maintain complete control over production – from anywhere, anytime.

5. Real-World Applications in Indian Industries

AKNITech’s IoT-SCADA systems are already transforming multiple manufacturing segments across India:

| Industry Sector | IoT-SCADA Application | Impact |

| Automotive | Real-time assembly line monitoring | Reduced downtime, improved quality |

| Power & Energy | Load management via smart meters | Optimized energy use, 15% lower power waste |

| Food Processing | Temperature & batch data automation | Higher consistency and hygiene |

| Cement & Steel | Machine health monitoring | 20-30% longer equipment life |

| Water Treatment | Smart flow and pressure control | Remote access & 24/7 alerts |

Insight:

India’s manufacturing GDP contribution is projected to hit $1 trillion by 2030, and AKNITech is enabling this growth through reliable, scalable, and locally-supported automation.

6. Why Indian Manufacturers Trust AKNITech

There are hundreds of automation providers in India, but AKNITech’s strength lies in its end-to-end engineering capability.

We don’t just sell IoT products – we deliver working ecosystems.

Key differentiators:

- Localized Expertise: Deep understanding of Indian industry challenges.

- Cost-Effective Deployment: Up to 40% lower cost than foreign integrators.

- Trusted Partnerships: Works with brands like Rexroth, Selec, BELNO, and AVEVA.

- Custom Software: MIS and EMS integration built in-house.

- Dedicated Support: 24×7 service across central India.

This blend of affordability, customization, and service reliability has positioned AKNITech among India’s fastest-growing industrial automation companies.

7. The Power of Data: SCADA + IoT + MIS

Today, data is the new electricity.

By connecting IoT devices, SCADA software, and MIS dashboards, AKNITech transforms raw factory data into actionable intelligence.

Manufacturers can:

- Track real-time machine performance.

- Compare energy use per production batch.

- Generate reports automatically.

- Identify inefficiencies and optimize output.

It’s not just automation – it’s digital transformation, designed specifically for Indian operations.

8. Future of Smart Manufacturing in India

According to McKinsey India, smart manufacturing can boost industrial productivity by up to 25% by 2030.

Technologies like AI-powered IoT, Edge Computing, and Digital Twins are paving the way for Industry 5.0, where human expertise meets machine intelligence.

AKNITech is already adapting these trends into its roadmap:

- Deploying AI-driven predictive analytics.

- Building cyber-secure IoT frameworks.

- Enabling mobile SCADA dashboards for plant managers.

By keeping pace with global innovation, AKNITech ensures that Indian industries remain competitive, sustainable, and future-ready.

9. Comparing Global vs Local IoT-SCADA Solutions

| Feature | Global Brands (Siemens / ABB / Honeywell) | AKNITech (India) |

| Implementation Time | 6-12 months | 2-3 months |

| Cost Range | ₹80-100 Lakhs+ | ₹30-45 Lakhs (Custom-built) |

| Support Availability | Centralized | Local & On-site |

| Integration Level | Product-based | System-based (IoT + SCADA + MIS) |

| Adaptability | Fixed modules | Flexible & industry-specific |

AKNITech offers faster, affordable, and more flexible industrial IoT and SCADA integration, perfectly suited for Indian-scale manufacturing setups.

10. The Road Ahead: Connected, Efficient, and Sustainable

AKNITech’s long-term vision aligns with India’s Make in India and Digital Manufacturing missions.

By combining IoT, SCADA, PLC panels, and Energy Management Systems, the company is creating an intelligent ecosystem that connects people, machines, and processes.

“Our goal is simple – to make Indian industries globally competitive through intelligent automation.”

– AKNITech Engineering Team With every project, AKNITech brings India closer to its dream of a smarter, self-reliant, and energy-efficient manufacturing future.