Introduction to VFD Programming

VFD programming is necessary for controlling the speed and torque of electric motors. What is VFD full form and what is its meaning for enhancing industrial motor drives? Variable Frequency Drive (VFD) programming has become a crucial part of energy efficiency and performance improvement, with automation developing further. It offers accurate control of motor speed, minimizes energy usage, and increases the lifespan of equipment.

Fundamentals of VFD Systems

You may have clarity on what VFD is in electrical systems. A VFD controller controls the frequency and voltage of the motor, controlling motor speed. Variable Frequency Drive (VFD) working principles are based on converting the fixed-frequency AC power to variable frequency and controlling the motor speed designed according to the machine’s requirements. Such flexibility allows for tailored motor performance as per the unique requirements of the application for better process control and reduced mechanical stress.

Exploring VFD Drive Mechanisms

A variable frequency drive (also known as a VFD drive working principle) consists of 5 distinct components that work together to perform an operation. The basic working principle is that first AC input is rectified to DC power, then inverted back to AC with a different frequency and voltage. It enables fine motor control and efficiency. There are different types of VFD, such as voltage-source inverters, current-source inverters, which serve different industrial applications. Proper VFD connection plays a key role in ensuring the smooth running of the motor and avoiding any electrical fault. Proper wiring, grounding, and parameters to avoid harmonics and overheating

Step-by-Step VFD Programming

Setting motor parameters (voltage limit, current limit, frequency limit, etc.) is the basis of VFD programming as follows. VFD drives should be programmed according to the VFD programming manual to avoid making mistakes. These are all parameters (acceleration and deceleration times, torque limits, and permissive safety) that must be configured to achieve optimal performance. Lenze VFD programming is known for its user-friendly nature and full-scale functions, which are easy to program, and the monitoring is real-time.

Advanced VFD PLC Integration

Aside from VFDs, the systematic integration of VFD programming in PLC systems will enhance seamless communication interaction between VFD and programmable logic controllers. It enables automated process control, on-the-spot data collection, and remote monitoring. Advanced VFD PLC programming typically involves configuring communication protocols such as Modbus or Profibus, setting up input/output signals, and writing application-specific custom logic. Practical VFD programming practice will allow electrical engineers to learn these integrations and troubleshoot in the event of issues.

Applications and Troubleshooting

Some of the most common applications for VFDs include HVAC, conveyor belts, water treatment plants, and manufacturing. The VFD connection and understanding that the VFD will function to prevent overheating, voltage spikes, and motor failures are important. Additional care by checking loose connections, monitoring the temperature, and updating the firmware can extend the life and efficiency of the VFD electrical inverter. Resolving common issues like bad parameter configurations or communication issues increases the normal running time of the organic household process and decreases the downtime.

Future Trends in VFD Technology

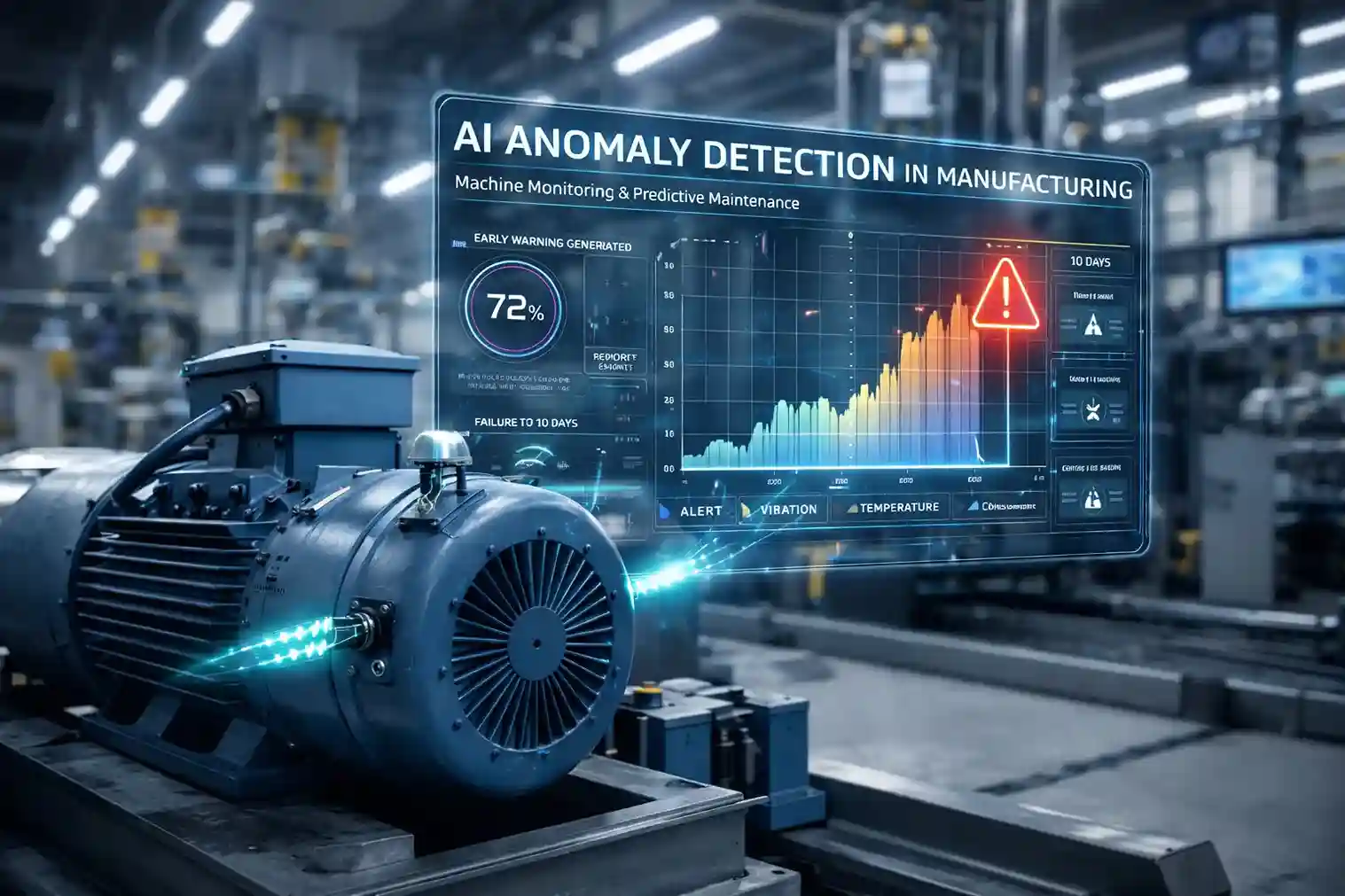

VFD programming is witnessing a transformation due to the power of AI and IoT. With enough computing power, smart VFD systems can track and analyze data while predicting failures before they occur and automatically optimizing performance. The innovations opened newer possibilities for more efficient as well as highly reliable motor control. Designs capable of eliminating excess generation, together with advanced materials to also enhance the duration of the complete system, are also integrated.

Conclusion

Obviously, the terms VFD Theory and Application are related to the craftsman’s making of VFD programming based on the VFD working principle, VFD drive working, and integration with PLC systems. With the correct practices and a few high-tech tools, engineers can accomplish more faster than ever before. This field is changing at a rapid pace, thus, we need to continuously learn and practice programming VFD drives and VFD programming in PLC systems.

Ready to excel in VFD programming and VFD PLC programming? Aknitech offers expert training and resources to help you achieve your goals. Visit aknitech.in today!