How Smart Automation India Is Transforming

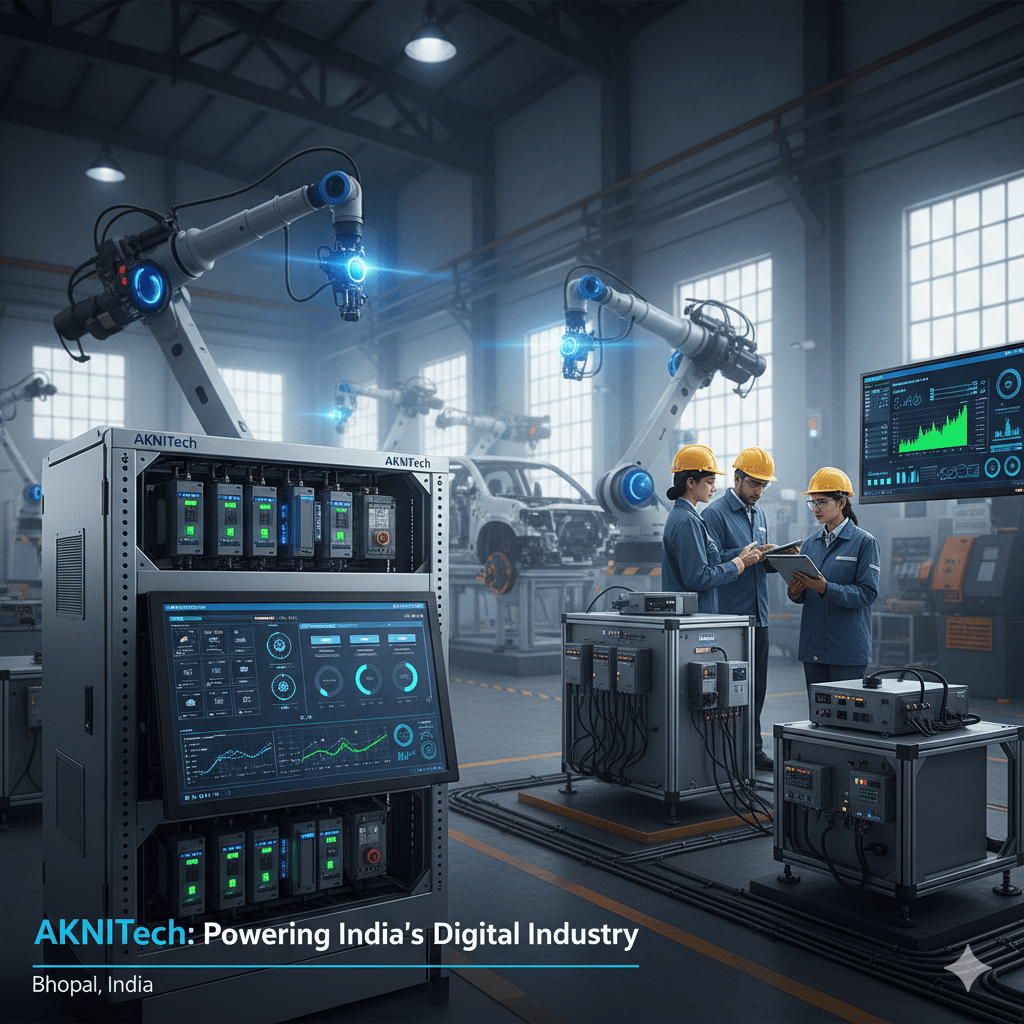

Manufacturing India’s sector is moving toward a new era of digital transformation From automotive plants to small industrial units, companies are investing in smart automation systems to improve efficiency and reduce human error. At the center of this evolution stands AKNITech, a trusted industrial automation and PLC manufacturing company based in Bhopal.

Through its expertise in PLC panels, SCADA design, IoT device management, and energy management systems, AKNITech helps industries optimize processes, lower energy costs, and build smarter, data-driven operations.

Why Smart Automation India Is Transforming Manufacturing

Automation is no longer a luxury-it’s a necessity. In modern plants, even a small delay or manual error can lead to large production losses.

A well-designed automation setup ensures:

Consistent quality and reduced downtime

Real-time monitoring of machinery performance

Lower operational and maintenance costs

Safer working environments for operators

By integrating PLC control panels and IoT-based monitoring systems, manufacturers can analyze performance trends and take preventive action before a fault occurs. This is exactly where AKNITech’s automation solutions bring measurable value.

AKNITech’s Smart Automation Capabilities

1. Advanced PLC and SCADA Systems

AKNITech designs PLC panels and SCADA systems play a major role in Smart Automation India software that manage complex industrial operations with precision.

These systems automate repetitive tasks, control power flow, and ensure that every unit of energy is used efficiently.

Whether it’s process automation in manufacturing or plant-wide monitoring, AKNITech ensures reliability and scalability.

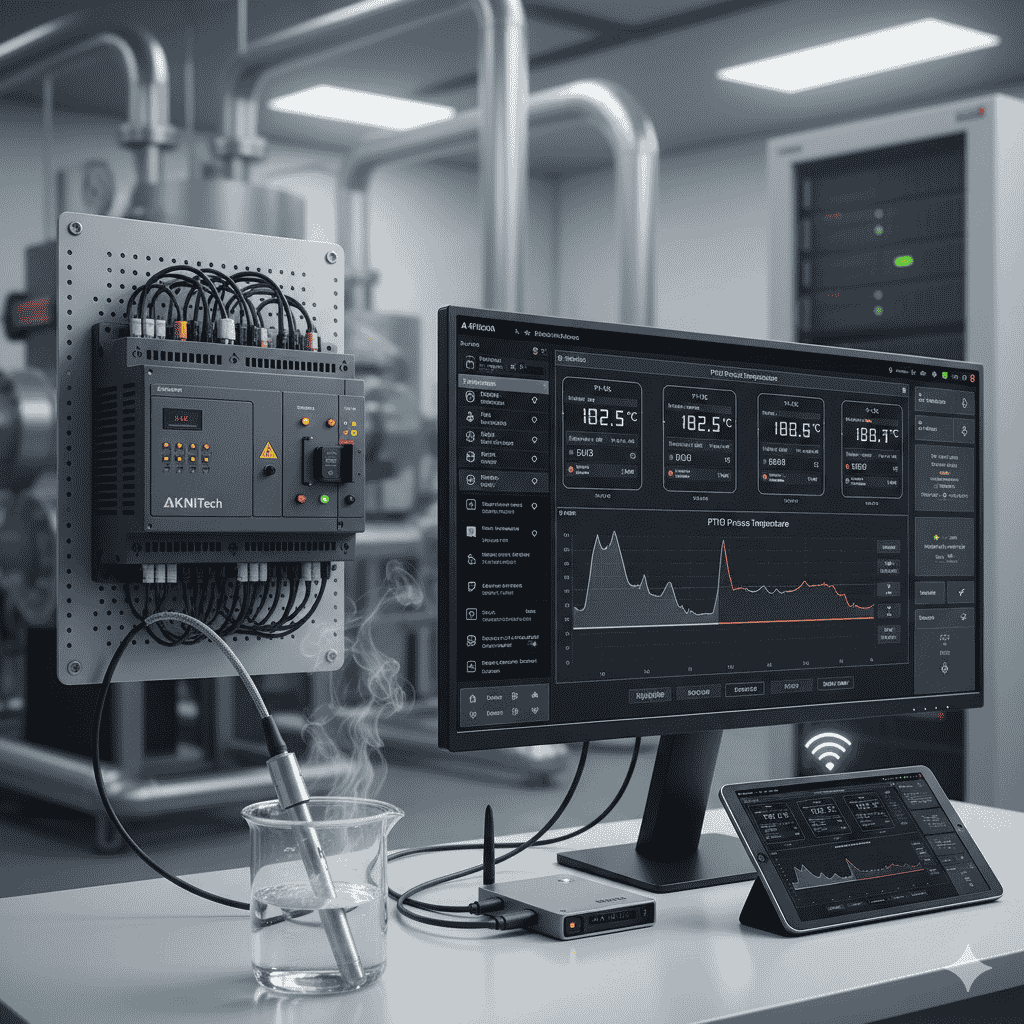

2. IoT-Enabled Process Optimization

With the rise of IoT device control and smart sensors, AKNITech connects machines and dashboards for real-time data collection.

This connectivity allows industries to monitor performance remotely, predict equipment failures, and achieve higher productivity.

Moreover, the integration of IoT with PLCs and MIS panels helps create an intelligent manufacturing ecosystem.

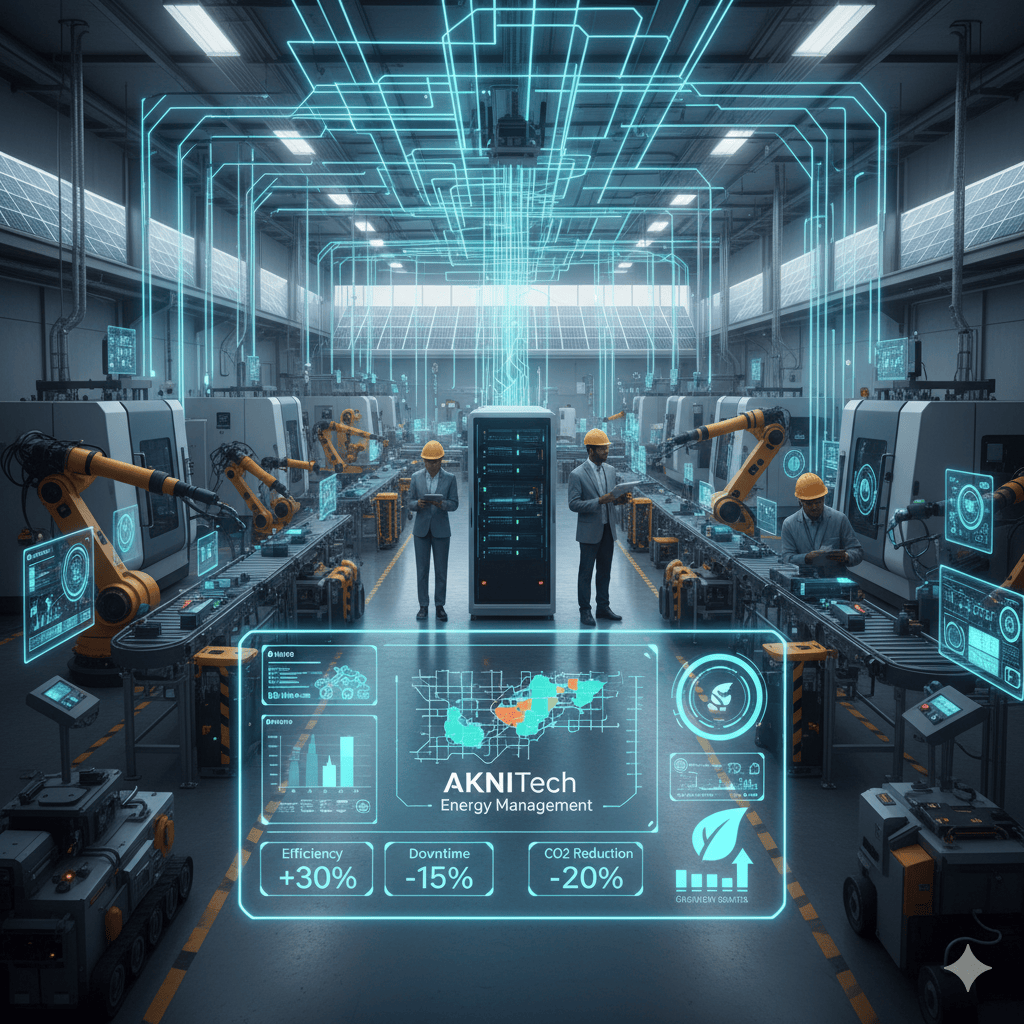

3. Energy Management and Sustainability

Energy costs are one of the biggest challenges for factories.

Through energy management systems and VFD/soft starter technology, AKNITech enables balanced power consumption and longer equipment life.

The result is lower energy bills, reduced carbon footprint, and a step toward sustainable industrial growth.

Driving Digital Transformation Across Industries

AKNITech’s automation solutions are already empowering sectors like:

Automotive manufacturing – for robotic welding and assembly control

Food and pharmaceuticals – for hygiene-critical process automation

Water treatment and irrigation – for smart monitoring and flow control

Power and heavy machinery – for energy optimization and remote operations

Each solution is tailored to meet specific industrial needs, combining hardware, software, and intelligent analytics into a single ecosystem.

The Future of Indian Manufacturing with Smart Automation

India’s vision of “Make in India” and Industry 4.0 relies heavily on the adoption of smart automation technologies.

As more factories embrace IoT-driven systems and data analytics, companies like AKNITech will continue to play a critical role in shaping a connected, efficient, and sustainable industrial future.

By investing in PLC-based control systems, SCADA design, and MIS automation, Indian manufacturers can achieve precision, agility, and long-term competitiveness in global markets.

Partner with AKNITech for a Smarter Tomorrow

AKNITech isn’t just a service provider-it’s a growth partner for industries aiming to modernize their operations.

From designing PLC panels to implementing IoT-based process automation, AKNITech delivers end-to-end solutions that help factories perform better and save more.

If you’re ready to embrace smart automation in India’s manufacturing ecosystem, connect with AKNITech today and start building your future-ready facility.