In today’s fast-paced industrial world, every second of machine downtime can cost thousands. Factories across India are realizing that relying on manual monitoring or outdated systems leads to delays, inefficiency, and unnecessary energy loss. That’s why SCADA and PLC in Industrial Automation have become essential – offering real-time control, accurate data collection, and smarter decision-making for modern manufacturing units.

The Growing Need for Real-Time Data in Manufacturing

That’s why real-time data collection with SCADA and PLC systems has become the foundation of modern manufacturing.

These smart automation tools empower industries to track operations instantly, make data-driven decisions, and achieve seamless production – all from a single dashboard.

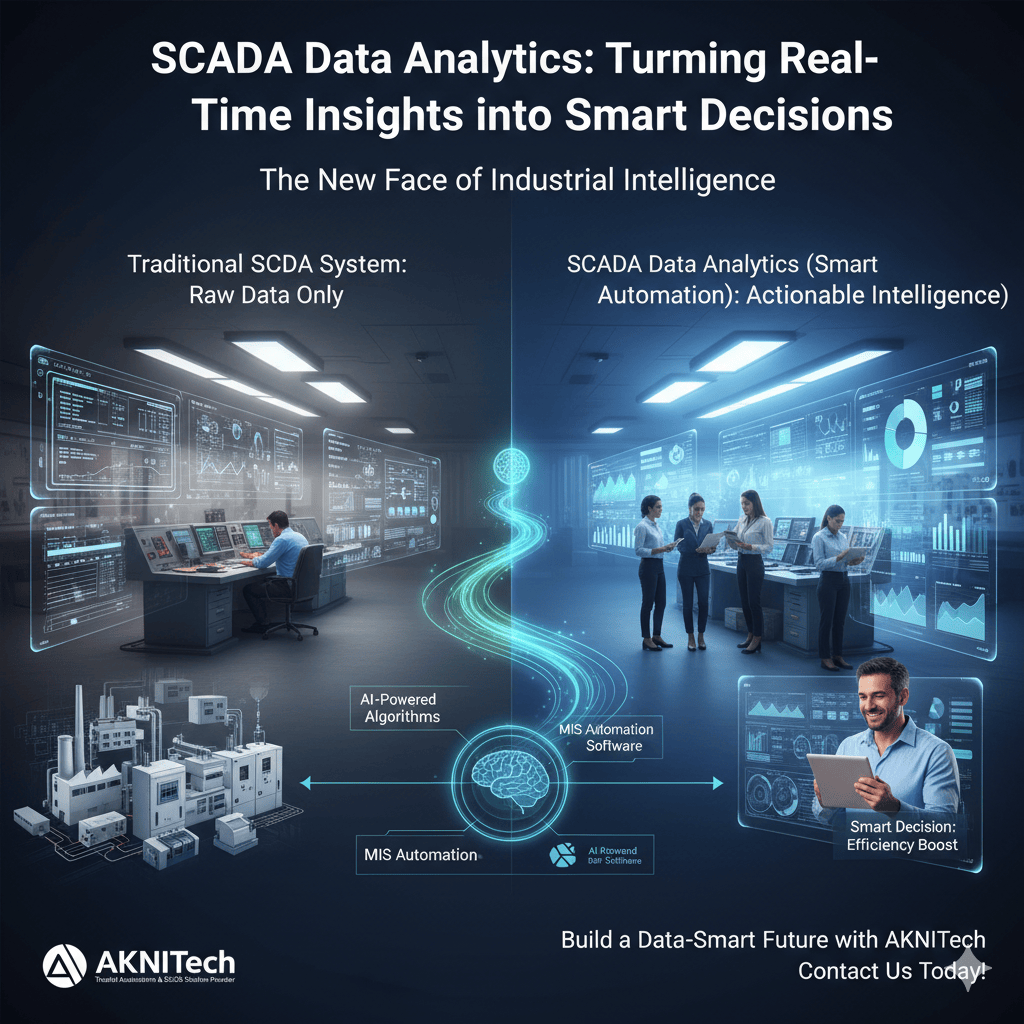

Understanding Real-Time Data Collection with SCADA and PLC In Industrial Automation

SCADA (Supervisory Control and Data Acquisition) and PLC (Programmable Logic Controller) work together as the brain and nervous system of an industrial plant.

SCADA collects, visualizes, and monitors live process data across machines and departments.

PLCs execute real-time control commands and ensure accuracy in production cycles.

When combined, they enable complete automation, from data collection to performance analysis.

This integration allows manufacturers to gain real-time insights into machine health, energy use, temperature, speed, and output – ensuring faster and smarter decisions.

The Problem: Manual and Delayed Data Collection

Many factories still depend on manual logging, paper records, or basic digital spreadsheets for performance tracking.

This leads to serious challenges:

Delayed responses to system faults or breakdowns

Energy waste due to inefficient process control

Limited visibility into equipment performance

Higher maintenance and downtime costs

Without real-time data, industries are essentially operating blind – reacting after issues arise rather than preventing them in advance.

The Solution: Smart Automation Through SCADA and PLC Systems

Implementing SCADA and PLC-based automation changes how industries operate.

Instead of waiting for problems to occur, factories can now detect and address issues instantly.

Here’s how AKNITech’s smart automation systems make it possible:

- Continuous Data Flow:

PLCs collect signals from sensors and transmit them to the SCADA system every second. - Instant Visualization:

SCADA dashboards show live parameters like voltage, temperature, and pressure for quick decision-making. - Predictive Alerts:

Integrated analytics warn operators before a fault or overload occurs. - Centralized Control:

Multiple machines and plants can be managed from one connected platform.

Through this system, factories can achieve real-time control, improved efficiency, and reduced manual intervention – a perfect example of Industry 4.0 in action.

Key Benefits of Real-Time Data Collection with SCADA and PLC

| Benefit | Impact on Industry |

| Reduced Downtime | Identify and resolve issues instantly to keep production running. |

| Improved Energy Efficiency | Optimize equipment performance and cut unnecessary power use. |

| Higher Product Quality | Maintain precision in process parameters for consistent output. |

| Predictive Maintenance | Detect faults before failures occur, saving repair costs. |

| Remote Accessibility | Monitor and control operations from anywhere, anytime. |

| Data Transparency | Enable clear insights for audits and performance reviews. |

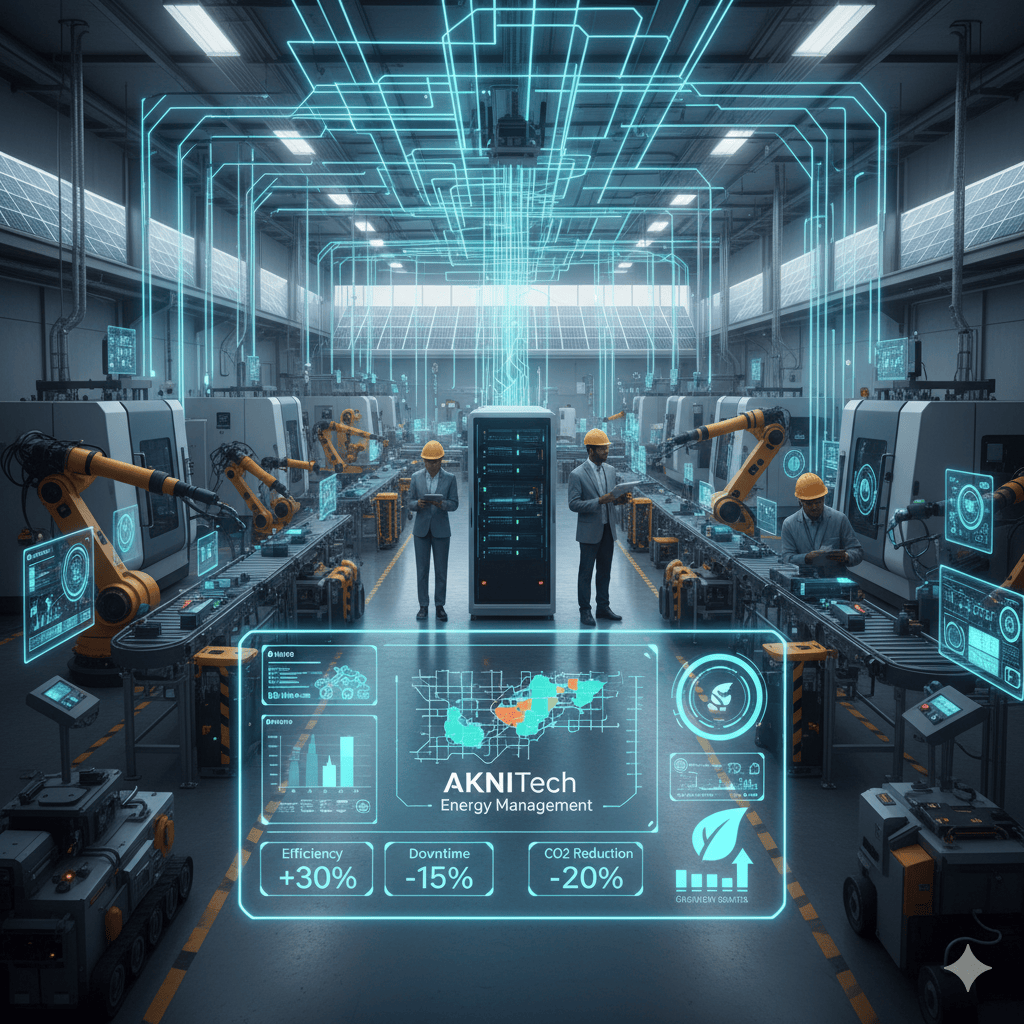

With these benefits, industries in Bhopal, Indore, and across India are adopting SCADA and PLC integration to modernize their production floors.

AKNITech Expertise in SCADA and PLC Automation

As a leading industrial automation company, AKNITech specializes in designing SCADA systems and PLC control panels that simplify real-time monitoring.

Their solutions are tailored for sectors such as manufacturing, energy, water treatment, and process industries.Advanced PLC control panels for precise operations

SCADA dashboards with IoT connectivity and MIS automation

Integration with energy management systems for optimized power usage

On-site setup, calibration, and maintenance support

With AKNITech’s automation solutions, businesses can achieve better control, higher reliability, and faster ROI.

The Future: Smart Factories Built on Real-Time Data

The future of manufacturing lies in data-driven decisions.

With technologies like SCADA, PLC, and IoT working together, factories are evolving into self-learning, efficient, and sustainable ecosystems.

These connected systems not only improve productivity but also reduce human errors and operational costs.

Build Smarter Operations with AKNITech

Data is the heartbeat of every smart factory – and real-time data collection through SCADA and PLC in Industrial Automation makes it stronger.

By adopting AKNITech’s automation solutions, industries can monitor, analyze, and optimize every process with unmatched accuracy. Partner with AKNITech today to turn your industrial data into real-time insights and create a truly intelligent manufacturing ecosystem.