If you’re running a factory in 2025, you already know the pressure. Expectations are higher. Customers want faster turnaround. Costs are rising. And one small delay in production? That could throw off an entire week’s schedule. Here’s the truth: traditional, manual systems just can’t keep up anymore. They’re slow, unpredictable, and give you very little visibility.

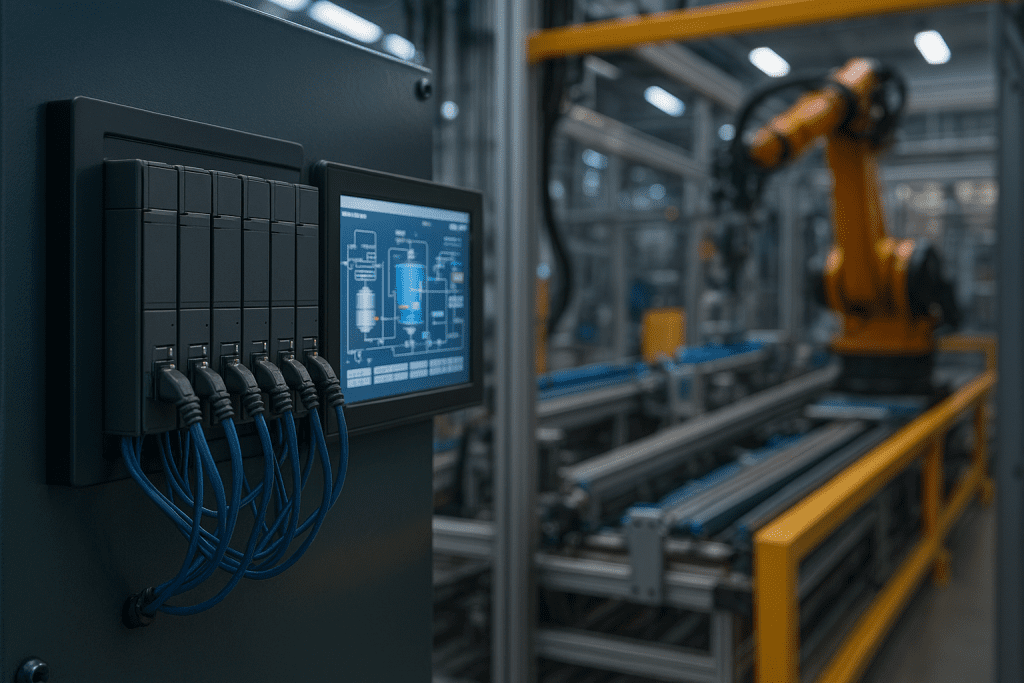

That’s why more manufacturers are turning to PLC automation and IoT device monitoring. These two technologies, when used together, can completely change how a plant runs, from the way machines respond, to how data is tracked, to how problems are spotted before they cause downtime.

What Is PLC Automation in Manufacturing?

A PLC, short for Programmable Logic Controller, is like the brain behind your machines. It’s a compact computer that controls your processes automatically, whether it’s a motor starting up, a conveyor belt moving, or a machine adjusting to different loads.

The beauty of a well-built PLC control panel is that once it’s programmed, it just works. It runs your operations exactly the way you want them, every single time. It also helps reduce human error, increase consistency, and ensure your equipment runs more safely and efficiently.

If you’re sourcing from reliable PLC manufacturers in India, you’ll find that today’s PLC systems are more adaptable and affordable than ever, making them a smart investment for any factory.

What Is IoT Device Monitoring in Manufacturing?

Now let’s talk about IoT, or the Internet of Things. In simple terms, IoT device monitoring means putting sensors on your equipment to collect real-time data—things like temperature, pressure, energy consumption, or vibration.

This data doesn’t just sit there; it goes to a dashboard where you (or your team) can see what’s happening inside your machines. Think of it as giving your factory a voice.

With proper IoT system management, you’re no longer guessing why a machine failed—you already saw the early signs and handled it. Understanding the different IoT levels helps you scale from basic monitoring to fully connected, automated control.

These kinds of IoT devices are now a standard part of modern manufacturing, and for good reason.

Common Problems in Traditional Manufacturing

Here’s what we often hear from factories still relying on outdated systems:

- “Machines shut down without warning.”

- “We find out there’s a problem only after production stops.”

- “Our energy bills are way too high, but we don’t know why.”

- “We’re still using manual logs to track production.”

- “We’re too dependent on a few skilled technicians.”

Sound familiar? These are exactly the kinds of issues that PLC integration and IoT device management solve by automating your processes and giving you eyes on everything.

Benefits of Combining PLC Automation with IoT Monitoring

Here’s where the magic happens—when you bring both systems together.

- You get real-time control of machines, whether you’re on-site or remote.

- You can schedule maintenance before something breaks.

- You’ll use less energy because your equipment is working smarter.

- You can pull accurate reports whenever you need them.

- And with SCADA systems connected to your IoT devices, you get a single dashboard view of everything.

This combination gives you peace of mind. You’ll know what’s going on, and you can react fast when something isn’t right.

2025 Trends in Manufacturing Automation

This year, more manufacturers are embracing the shift to smart factories. With industrial IoT growing rapidly, businesses are moving from reactive to proactive strategies.

You’ll see more use of connected machines, cloud-based SCADA, and smart alerts. And with labor shortages still being a major concern, automation is helping plants run efficiently with leaner teams.

We’re also seeing more interest in scalable systems, like modular PLC integration and flexible IoT device monitoring setups, that grow as your operations grow.

Why Choose AKNItech

At AKNItech, we don’t just sell equipment, we build complete, reliable automation solutions. Whether it’s a simple PLC control panel, a custom-built SCADA system, or a full-scale IoT monitoring setup, we tailor everything to your specific needs.

Our goal? To help your factory run smoother, safer, and smarter, without overcomplicating things.

Ready to Optimize Your Factory for 2025?

You don’t need to rip everything out and start over. But you do need to start thinking differently.

If you’re ready to reduce downtime, take control of your data, and bring smarter automation into your plant, let’s talk.

Reach out to our team today. We’ll walk you through what’s possible, what’s practical, and how to get started—step by step.

Let’s build a smarter, future-ready factory. Together.