In 2025, industrial automation in IoT is rapidly transforming the way industries operate. From manufacturing floors to energy plants, the shift from manual to smart automation is driven by one key factor: IoT device management. Managing and monitoring machines has never been more seamless, and businesses that adopt IoT-driven systems are seeing big gains in efficiency, safety, and performance.

Let’s explore how IoT device monitoring, SCADA systems, and PLCs are powering the future of industrial automation in IoT.

What Is Device Management in IoT and Why It Matters

To understand the role of IoT device management, it’s important to start with the basics. What is device management in IoT? It’s the process of onboarding, controlling, monitoring, and updating connected devices in a secure, efficient way. In industries, this can mean keeping track of hundreds or thousands of machines across multiple sites.

With smart IoT monitoring devices, businesses can detect problems early, push remote updates, and analyze data in real time. Common IoT device examples include temperature sensors, motion detectors, energy meters, and access control systems—all essential to smooth operations.

Smart Upgrades: From Traditional to IoT Industrial Automation

The rise of IoT industrial automation means moving beyond isolated systems toward intelligent, integrated workflows. One of the core components of this shift is the industrial PLC. These programmable logic controllers automate repetitive processes and keep systems running smoothly.

By connecting these PLCs to a central IoT device management platform, industries gain complete visibility and control over machines in real time. With PLC industrial automation, tasks like packaging, sorting, or environmental monitoring can be optimized effortlessly.

This is where the true value of industrial automation in IoT begins—when machines not only operate but also communicate.

SCADA and IoT: Smarter, Real-Time Industrial Monitoring

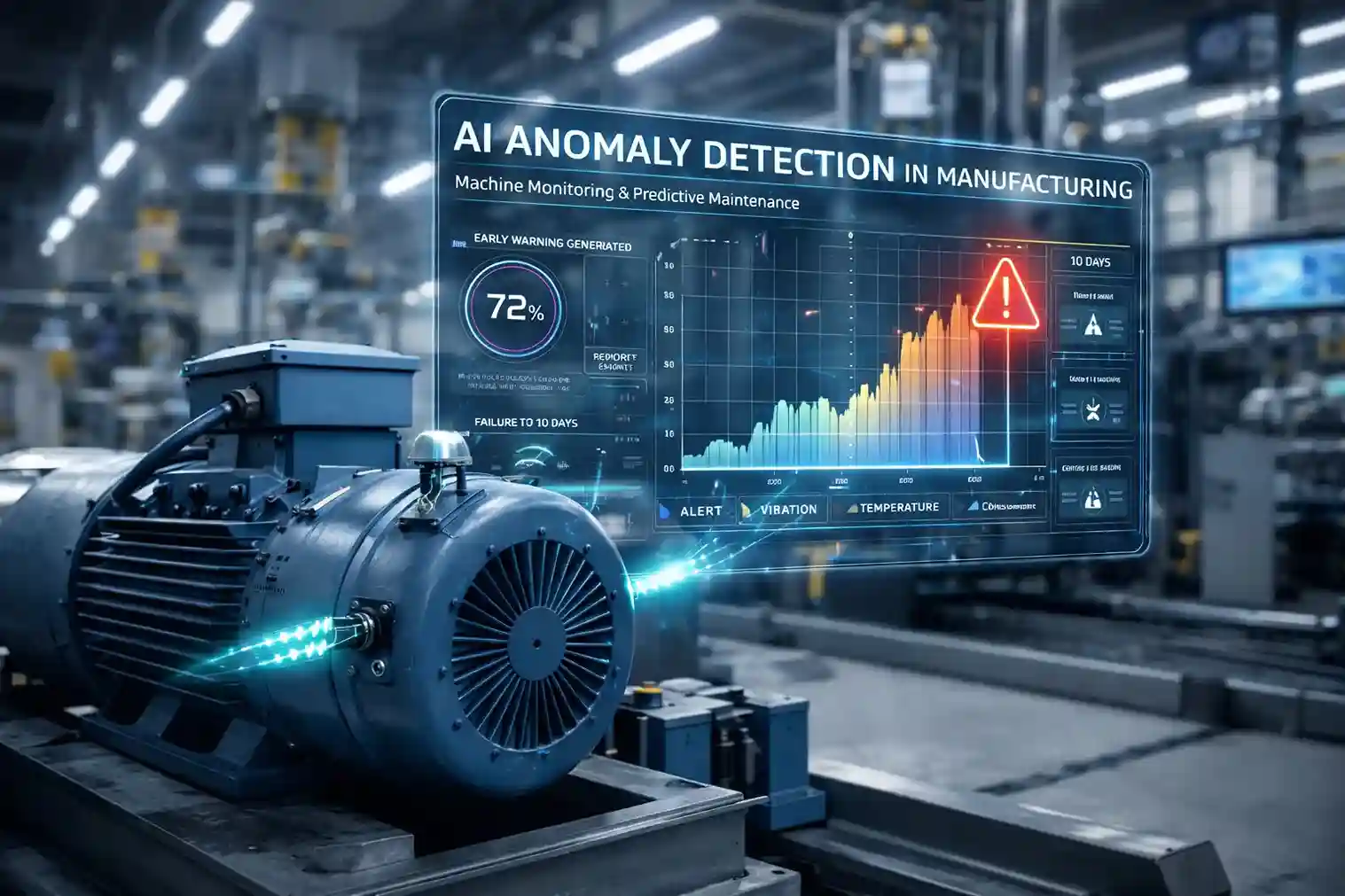

SCADA systems have long been used to supervise industrial operations. But with IoT integration, SCADA and IoT work together to bring intelligent insights. A SCADA IoT setup collects data from connected devices, analyzes performance, and alerts teams to issues before they escalate.

Paired with IoT device monitoring, SCADA becomes a powerful tool for real-time diagnostics, remote monitoring, and smart automation across complex systems.

Top Benefits of Industrial Automation in IoT

Here’s why more industries are embracing industrial automation in IoT:

- Better visibility across operations

- Predictive maintenance using IoT monitoring devices

- Faster response times and fewer breakdowns

- Energy and cost savings

- Safer environments with less manual intervention

These are just a few of the many advantages of industrial automation when powered by IoT.

Partner with Aknitech for Smart Industrial Automation

At Aknitech, we specialize in end-to-end industrial automation services. Whether you’re upgrading legacy systems or launching a new plant, we bring the tools and expertise—IoT device management, SCADA integration, and PLC solutions—to help you scale securely.

Let’s Build Your Smart Factory Together

Embrace the future of industrial automation in IoT with Aknitech.

Visit us today and explore scalable, intelligent automation solutions designed for your business.