In modern industries, every second and every data point matters. Machines constantly generate information that often goes unused. Without proper analysis, this raw data holds little value.

That’s where SCADA Data Analytics comes in – transforming real-time operational data into actionable intelligence.

Companies like AKNITech, a trusted automation and SCADA solution provider in Bhopal, are helping Indian manufacturers convert data into smarter, faster, and more profitable decisions.

What Is SCADA Data Analytics and Why It Matters

SCADA (Supervisory Control and Data Acquisition) systems collect, control, and visualize data from industrial machines and processes. When combined with analytics, SCADA evolves from a monitoring tool into a powerful decision-making system.

Through SCADA Data Analytics, industries can:

Detect process deviations before breakdowns occur

Predict failures and reduce downtime

Optimize energy consumption

Improve scheduling and production flow

With these capabilities, plants no longer react to problems – they anticipate and prevent them, ensuring continuous, cost-efficient operations.

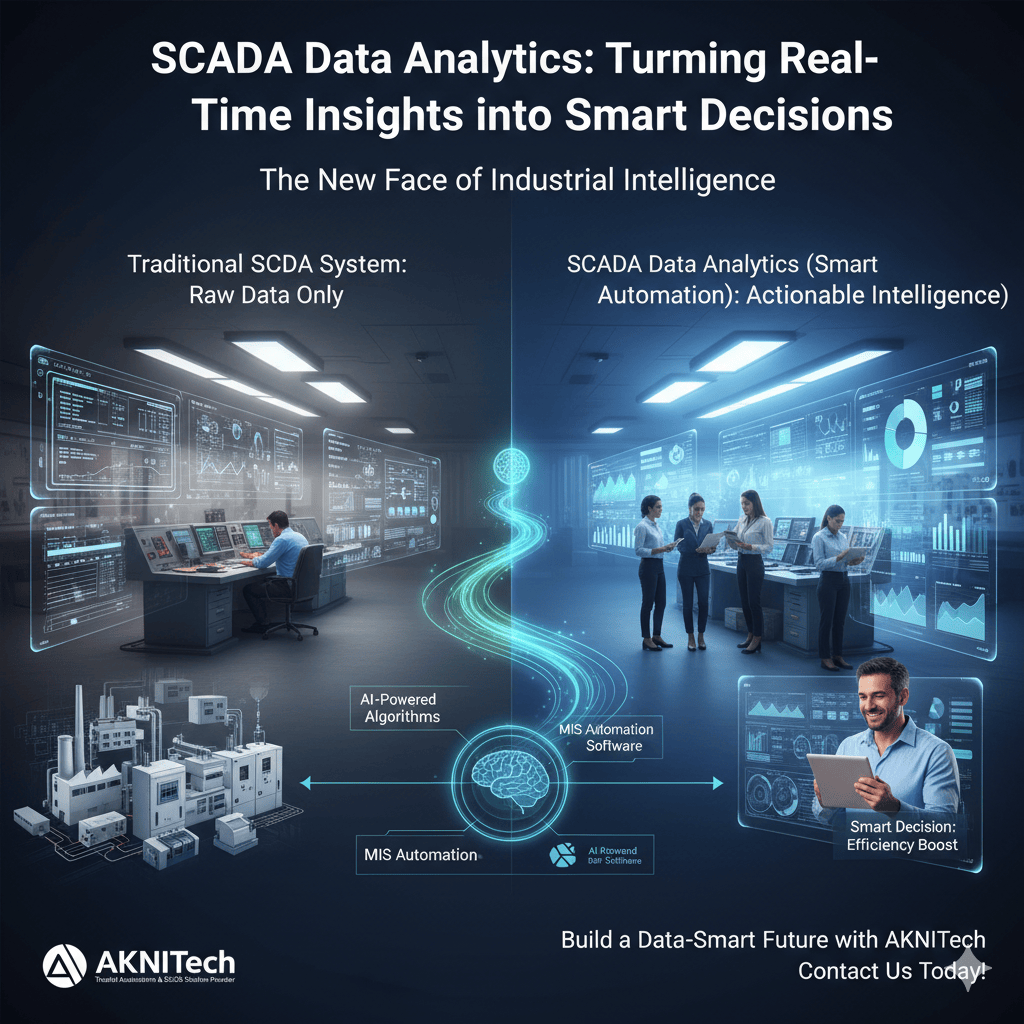

How SCADA Data Analytics Works: Process, Insights & Implementation

- Data Collection:

PLC panels, IoT sensors, and controllers collect real-time data from various processes. - Data Processing:

The SCADA system translates this raw input into easy-to-read dashboards. - Analytical Insights:

With AI-powered algorithms and MIS Automation Software, patterns, inefficiencies, and performance trends are detected automatically. - Smart Decision-Making:

Managers receive precise alerts and recommendations to improve productivity and energy efficiency.

This loop turns data into decisions, empowering industries to stay ahead of competition.

Traditional SCADA vs. SCADA Data Analytics: A Smart Industry Comparison

The shift from monitoring to intelligence defines the future of automation.

Here’s how modern SCADA Data Analytics changes the game:

| Feature / Aspect | Traditional SCADA System | SCADA Data Analytics (Smart Automation) |

| Data Handling | Displays raw data only | Analyzes real-time data for insights |

| Decision Making | Reactive after an issue occurs | Predictive and proactive decision-making |

| Reporting | Manual trend charts | Automated MIS reports and insights |

| Integration | Limited to PLC/HMI | Seamless with IoT, AI, and cloud platforms |

| Energy Optimization | Basic monitoring | Real-time load balancing and efficiency control |

| Maintenance | Manual or time-based | Predictive through AI-based analytics |

| Scalability | Hard to upgrade | Modular and easily expandable |

| Accessibility | Local only | Remote access via web or mobile dashboards |

| Business Impact | Monitors processes | Improves performance, reduces cost, increases uptime |

Insight:

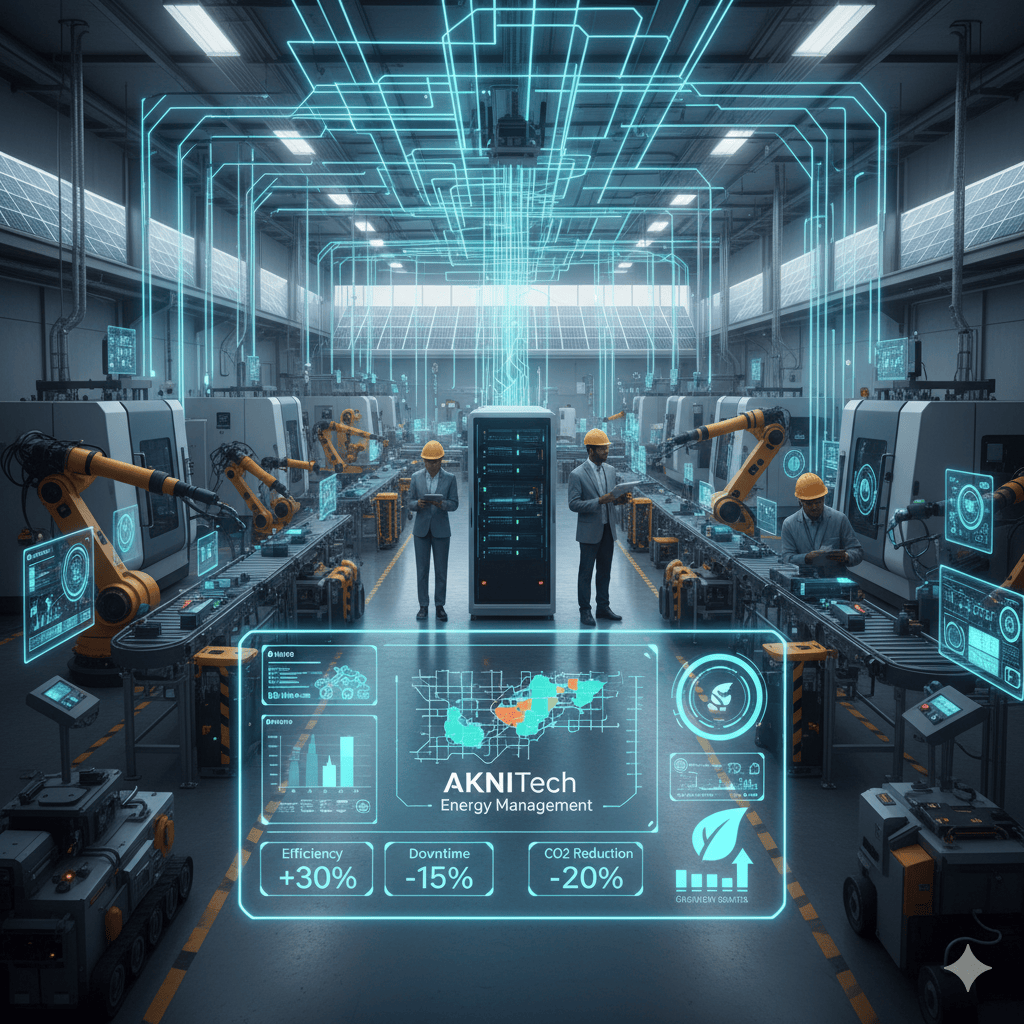

Upgrading from traditional SCADA to data-driven analytics can improve efficiency by 30–40%, reduce downtime, and enhance energy optimization across plants.

Integration of SCADA with IoT and MIS Automation

When SCADA systems, IoT devices, and MIS software work together, industries gain complete operational visibility.IoT sensors gather live data, SCADA visualizes it, and MIS software provides analytical reports – giving decision-makers a 360° view of plant performance.

This integration is key to achieving true Industry 4.0 transformation.

Key Benefits of SCADA Data Analytics

Real-time performance tracking across all equipment

Predictive maintenance and reduced downtime

Accurate reporting and data visualization

Optimized energy management and cost savings

Remote access for centralized control and monitoring

Whether it’s a power plant, water treatment facility, or manufacturing unit, AKNITech’s SCADA analytics solutions help drive measurable results.

Industries Benefiting from SCADA Data Analytics

Manufacturing – Enhanced quality control and productivity

Water & Irrigation – Smarter monitoring of water levels and flow

Power & Energy – Real-time grid control and renewable integration

Pharmaceuticals & Food – Consistent process monitoring for compliance

The Future of SCADA Analytics in India

The future belongs to data-driven industries.

With the integration of AI, IoT, and predictive analytics, SCADA will become more intelligent, self-learning, and efficient.

As India moves closer to Industry 4.0, AKNITech continues to lead the way – empowering factories with the tools they need to automate smarter, not harder.

Build a Data-Smart Future with AKNITech

Every factory has data – but only smart factories know how to use it.

With AKNITech’s SCADA Data Analytics, industries can transform real-time insights into smart business decisions.

From SCADA design to IoT integration and MIS reporting, AKNITech delivers solutions that redefine efficiency, reliability, and performance.

Ready to modernize your operations?

Contact AKNITech today and discover how SCADA Data Analytics can turn your plant into a smart, connected powerhouse.