Industrial plants in 2025 are under pressure to increase uptime, reduce manual intervention, and achieve real-time visibility across every machine and process. From manufacturing lines to water treatment plants, industries now demand systems that can monitor thousands of parameters, trigger instant alarms, and support remote decision-making.This shift has made HMI + SCADA integration one of the most powerful automation upgrades for modern industries. Instead of handling standalone dashboards, unlinked PLCs, and scattered control systems, factories now run centralized, intelligent interfaces that combine machine-level control (HMI) with plant-wide monitoring and analytics (SCADA).

This blog breaks down how HMI and SCADA work together, why HMI + SCADA integration matters in 2025, and how industries across India are adopting smarter automation systems for better efficiency and safety.

What Are HMI and SCADA?

HMI – Human Machine Interface (Machine-Level Control)

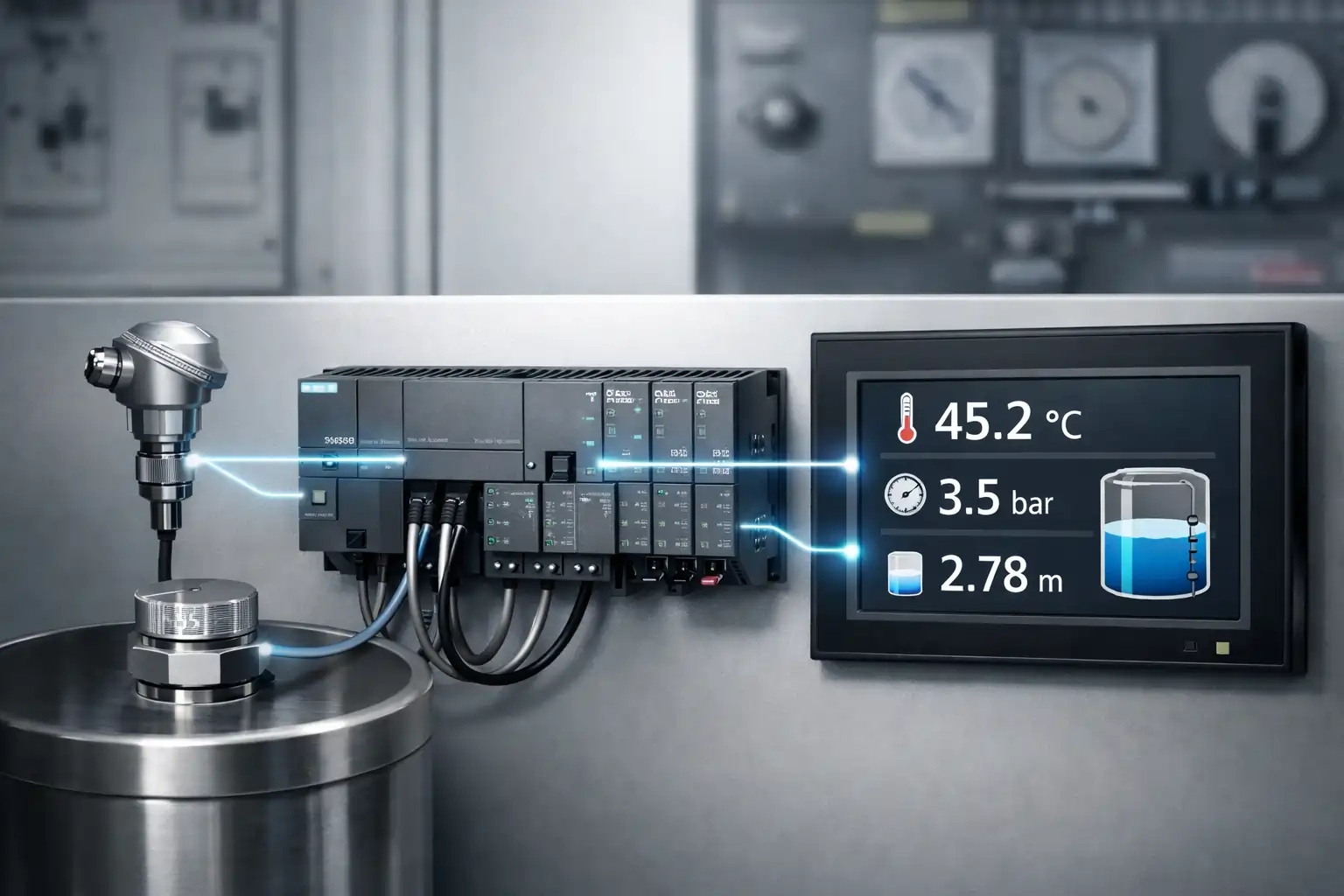

An HMI is the operator’s local interface to interact with PLC-based machines. It displays real-time values, trends, and faults directly connected to a specific machine or panel.

Functions of HMI:

- Start/Stop Machine Operations:

HMI provides direct access to start, stop, or pause the machine. Operators can initiate actions instantly without opening panels or using hardware push buttons. - Display Live Sensor Values:

HMIs continuously show data such as temperature, pressure, flow, vibration, and speed. This helps operators judge the machine’s health before faults occur. - Show Alarms and Interlocks:

Whenever abnormal conditions arise—overload, high temperature, low pressure—the HMI displays the alarm along with timestamp and fault source. - Change Setpoints:

Operators can modify parameters like motor speed, dosing levels, pressure cut-offs, or cycle timings within permitted limits. - Manual Overrides in Safe Mode:

Authorized personnel can temporarily override the automatic process (only when needed) using predefined safety rules. - Graphical Visualization:

Machines are represented with animated graphics, so operators can easily understand which component is running, stopped, or in fault mode.

HMIs are used in:

- Packaging machines

- Conveyors

- VFD panels

- Process control skids

- Injection molding, CNC support equipment

In short: HMI = localized machine visualization and control.

SCADA – Supervisory Control and Data Acquisition

SCADA is a supervisory system designed for entire plant monitoring, multi-machine control, historical logging, and remote operations. Modern systems increasingly integrate SCADA PROTOCOLS IN IOT environments to ensure smoother communication.

Functions of SCADA:

- Real-Time Monitoring of All PLCs:

SCADA aggregates data from every PLC, RTU, and field device. Managers can watch the complete plant from one dashboard. - Alarm Management:

It automatically categorizes alarms into critical, warning, or advisory groups — helping maintenance teams prioritize what to fix first. - Historical Data Storage:

SCADA stores months or years of data, allowing engineers to analyze long-term process behavior and improve efficiency. - Remote Control:

Motors, valves, feeders, blowers, pumps, and conveyors can be started or stopped remotely after proper authentication. - Production and Energy Dashboards:

Custom dashboards show KPIs such as energy consumption, batch output, pressure variations, and downtime trends. - Batch & Recipe Management:

Industries like food, chemical, and pharma use SCADA to manage complex recipes that need precision and consistency. - Audit Trails & Event Logs:

Every change made by any user is tracked—ensuring compliance with industrial standards.

SCADA connects to PLCs and RTUs using protocols like:

- Modbus TCP / RTU

- Ethernet/IP

- Profinet

- SCADA INTERNET OF THINGS for cloud-based monitoring

In short:

SCADA = centralized plant monitoring + data analytics + supervisory control.

Why HMI + SCADA Integration Matters in 2025

Industries no longer see HMI and SCADA as separate systems. When integrated properly, they create a unified operational ecosystem where local control and plant-level visibility work together seamlessly.

Below are the major reasons why this integration is essential in 2025:

1. Unified Visibility Across Machines and Processes

Operators use HMIs for machine-level control, but supervisors need plant-wide insights. Integrating both ensures:

- Every HMI parameter reflects instantly in SCADA

- SCADA can push commands or setpoints back to HMI

- Faults and alarms are synchronized across the plant

- No conflicting data between local and central monitoring

This unified view is strengthened further when combined with SCADA IOT dashboards.

2. Faster Decision-Making with Real-Time Data

In 2025, decision cycles are shorter. Energy costs, downtime, and process variability can’t wait for manual reporting.

Integration gives:

- Instant KPIs on SCADA

- Live machine conditions from HMIs

- Shift reports and audit trails

- Predictive maintenance insights through analytics

Robust IOT CONNECTIVITY ensures all devices communicate efficiently across the plant, enabling faster decisions.

3. Reduced Downtime Through Smart Diagnostics

Combined systems allow maintenance teams to access deep diagnostics:

- SCADA shows trends, historical faults, and energy patterns

- HMI shows machine-specific alarms and manual test options

When connected:

- Root causes become easier to trace

- Machine failures can be predicted

- Spare part planning becomes accurate

Well-structured IOT DEVICE MANAGEMENT helps maintain device reliability across complex industrial systems.

4. Remote Monitoring and Secure Control

2025 factories increasingly rely on remote supervision.

Integration allows:

- SCADA dashboards accessible through secure VPN/web servers

- Remote handling of pumps, motors, and process adjustments

- Immediate alarm notifications on mobile devices

- Safe override permissions controlled through SCADA

Secure IOT SYSTEM MANAGEMENT plays a vital role in maintaining access control and remote operation safety.

5. Improved Safety and Compliance

Automation standards now demand strict monitoring of alarms, interlocks, and trip conditions.

Integrated HMI+SCADA ensures:

- Every fault is logged and timestamped

- SCADA generates compliance reports

- Critical actions taken on HMI appear in SCADA event logs

- Operator authorization is managed securely

This directly improves safety and eliminates undocumented manual changes.

How HMI + SCADA Communicate (Technical Layer Overview)

1. PLC as the Middle Layer

Both HMI and SCADA connect to a PLC which handles machine logic. Today, industrial plants rely heavily on trusted PROGRAMMABLE LOGIC CONTROLLER MANUFACTURERS to ensure reliable hardware performance.

Data flow:

- HMI → PLC (local commands)

- SCADA → PLC (supervisory commands)

- PLC → both systems (real-time data)

2. Networking Layer (Ethernet / Serial / IIoT)

2025 systems mostly use:

- Industrial Ethernet

- Managed switches

- Redundant fiber networks

- VLANs for secure segmentation

- MQTT brokers for cloud connectivity

3. Tag Synchronization

Common data tags are shared:

- Motor status

- Valve positions

- Analog sensor readings

- Batch counters

- Alarms & interlocks

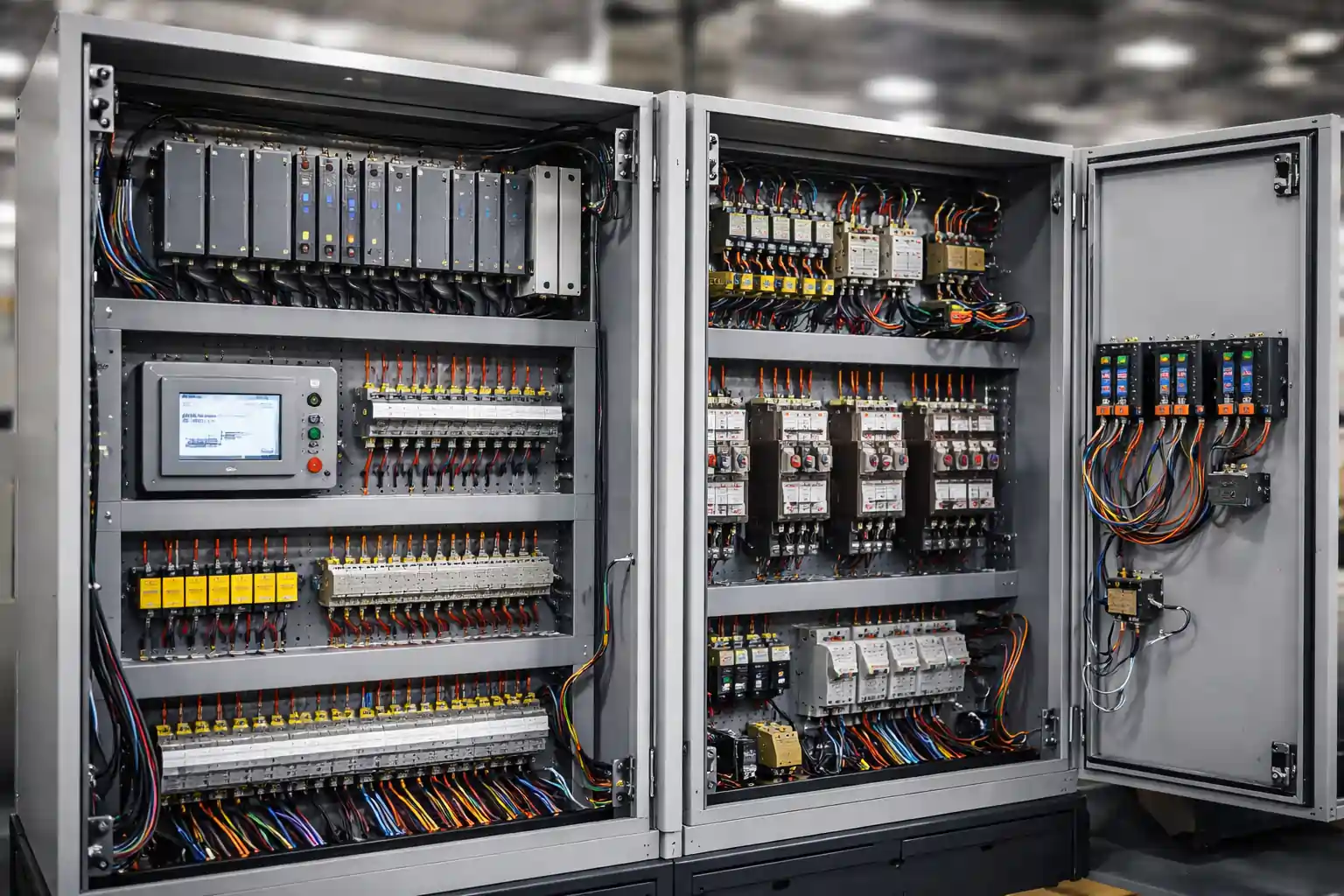

This ensures both systems show identical information.Many factories pair this with PLC ELECTRICAL PANEL architecture and optimized PLC CONTROL PANEL COMPONENTS for reliable operation.

Key Features of an Integrated HMI + SCADA System

1. Real-Time Alarms with Prioritization

- Critical

- Warning

- Advisory

SCADA generates central logs; HMI shows instant alerts.

2. Trending & Data Logging

- HMI: short-term trends

- SCADA: months or years of historical data

This helps in quality audits and predictive maintenance.

3. Energy Consumption Dashboards

VFDs, MCCs, and EMS panels can push live energy values to SCADA, helping factories track:

- kW

- kWh

- Power factor

- Harmonic distortion

Industries increasingly rely on a modern ENERGY MANAGEMENT SYSTEM IN INDIA to monitor these metrics accurately.

4. Centralized Recipe Management

SCADA manages recipes; HMIs execute them on machines.

5. Role-Based Access Control (RBAC)

Operators → basic parameters

Engineers → tuning, setpoints

Admins → configuration, overrides

Security becomes stronger and traceable.

Use Cases of HMI + SCADA Integration in Indian Industries (2025)

Water Treatment & Pumping Stations

- Pump control and flow monitoring on HMI

- SCADA showing plant-wide tank levels, pressure, chlorine dosing

- Remote pump switching

- Alerts for pump dry-run, overload, or low pressure

Manufacturing & OEMs

- Multi-machine production lines

- OEE monitoring

- Batch tracking and quality consistency

- Predictive alerts for motors and drives

Energy Management & Utilities

- Integration with VFDs and EMS panels

- Real-time energy dashboards

- Fault logging for feeders and panels

Food Processing

- Temperature and humidity tracking

- Recipe-based process automation

Smart Automation Panels

AKNItech’s control panels integrating PLC, HMI, and SCADA provide synchronized operations for complex industrial machines.

Why AKNITech Excels in HMI + SCADA Integration

AKNItech specializes in delivering complete industrial automation solutions for factories in Bhopal and across India.

The company’s expertise includes:

- PLC programming (Siemens, Allen Bradley, Delta, Schneider)

- HMI/SCADA designing using AVEVA, WinCC, InduSoft, and Weintek

- Industrial networking (managed switches, VLANs, fiber)

- VFD & motor control panel integration

- Smart dashboards and IoT-based reporting

- EMS + MIS software solutions

AKNItech’s integration approach focuses on:

- High-reliability logic

- Clean visualization

- Operator-friendly screens

- Strong industrial communication

- Secure remote access

- Fault-proof wiring and testing standards

This ensures long-term reliability, safety, and performance for every industrial client.

Conclusion

HMI + SCADA integration is becoming the backbone of industrial automation in 2025. With demands for remote access, real-time insights, predictive maintenance, and secure operations, industries can no longer rely on isolated systems.

A unified approach driven by HMI + SCADA integration simplifies control, enhances visibility, and ensures every machine—from a single VFD panel to an entire production line—operates efficiently and safely. As automation continues to advance, companies like AKNITech are helping industries transition to smarter, connected, and future-ready systems that deliver consistent performance and measurable results.