Modern factories in 2025 operate in an environment where efficiency, automation, real-time data, and sustainability define competitiveness. With rising electricity tariffs, expanding automation lines, and the rapid adoption of IoT and industrial digital systems, every plant now requires a reliable Energy Management System to optimize power usage and reduce operational waste.

With rising energy prices and increasing pressure for optimized production, factories need deeper control over electricity usage – a major reason why an energy management system in india has become crucial for modern industries. This is where Energy Management Systems (EMS) have become a core technology for future-ready industrial plants by improving how each plc electrical panel and machine uses power.

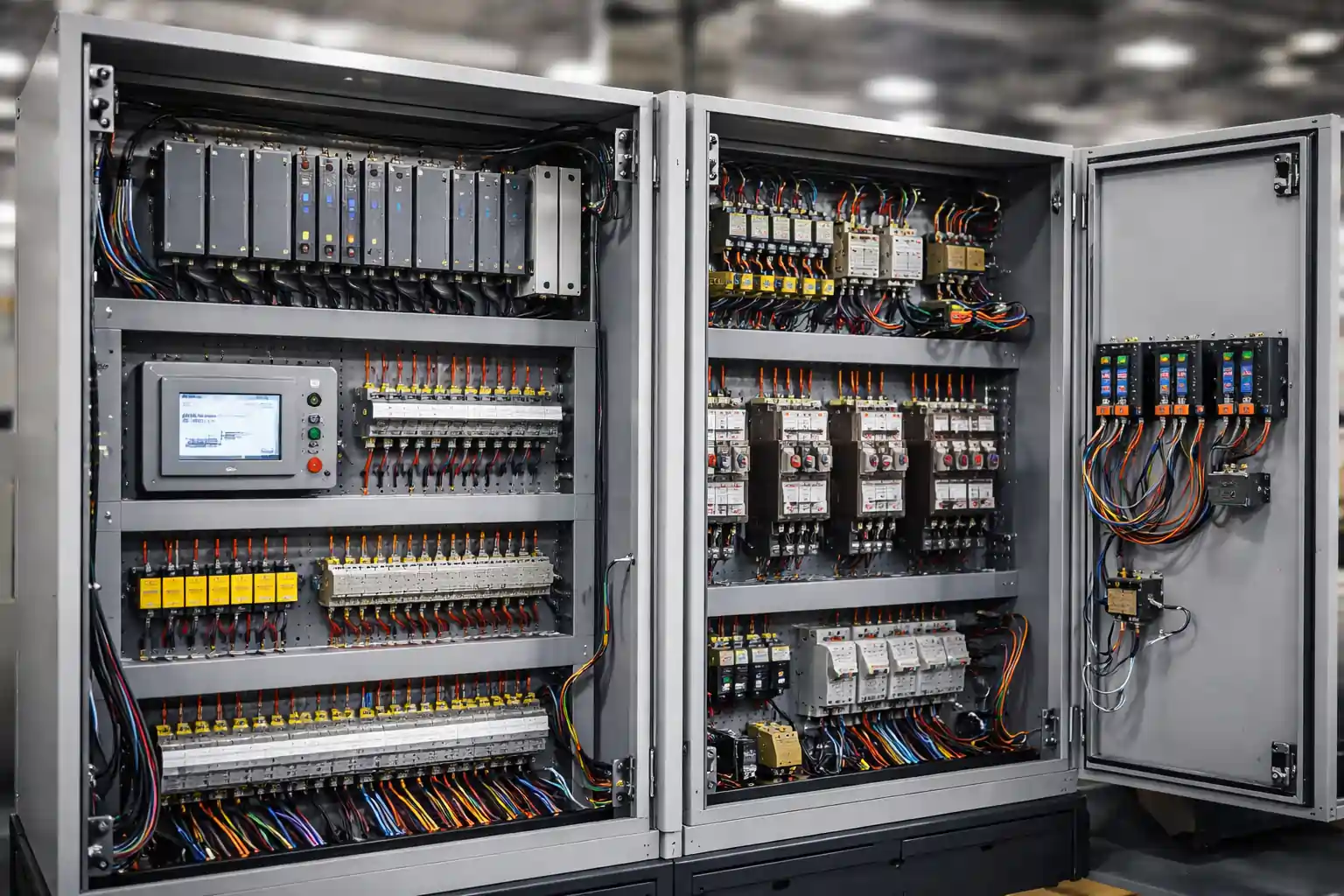

An EMS goes beyond simple monitoring by using advanced iot connectivity to gather real-time data from machines.It helps factories understand how energy flows through machines, including each plc control panel, where wastage happens, and what can be improved.When combined with IoT, SCADA, PLC systems, and VFD panels, EMS uses scada iot integration to deliver end-to-end control over energy efficiency and equipment performance.

What Is an Energy Management System ?

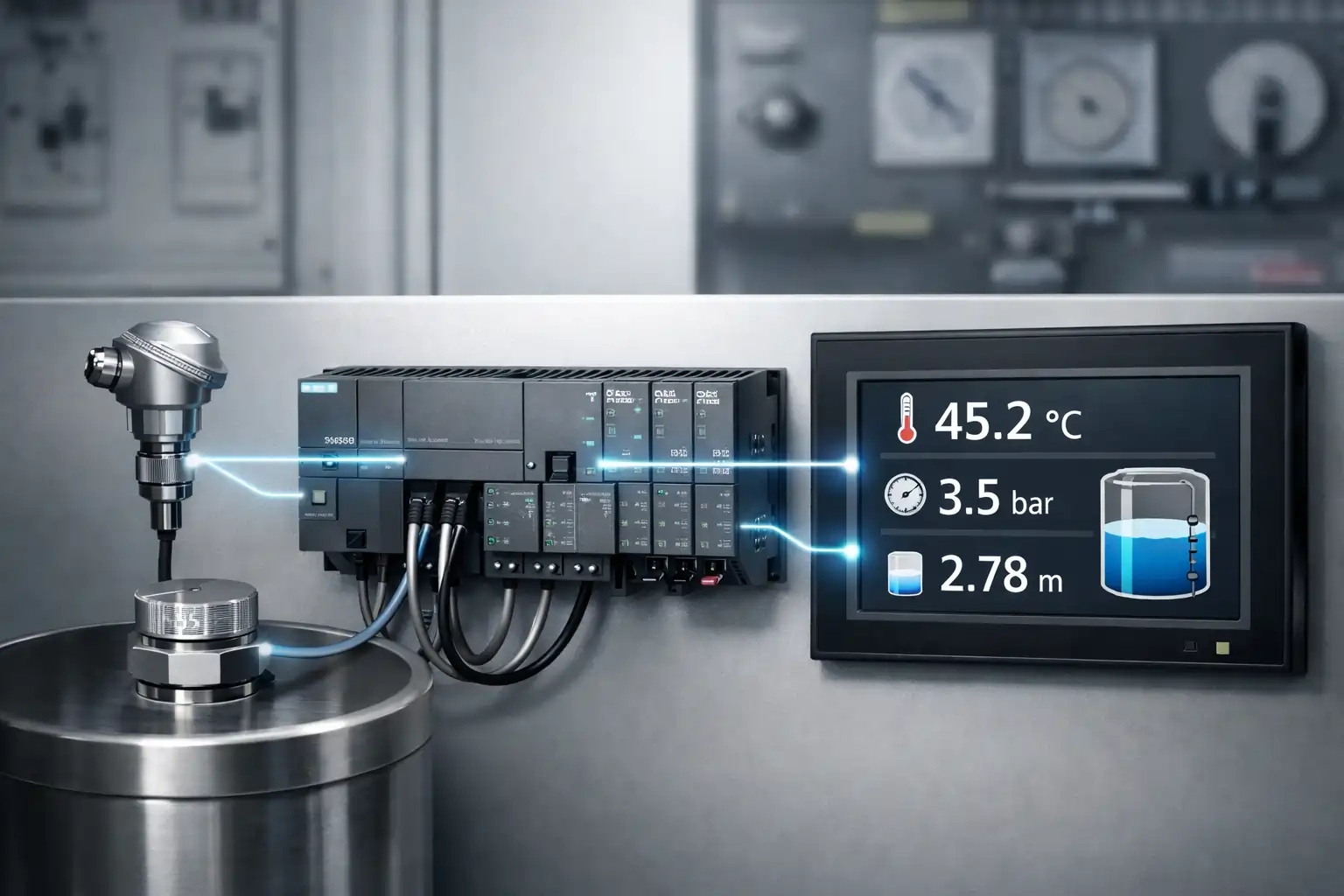

An Energy Management System is a digital platform that measures, analyses, controls, and optimises industrial energy usage through advanced iot device management.It connects with meters, PLCs, VFDs, sensors, subpanels, and SCADA networks using standard scada protocols in iot to capture live power data. The EMS then processes this information and presents it on dashboards, reports, alerts, and automated notifications.

An EMS typically includes:

- Smart Energy Meters

These meters measure electrical parameters such as voltage, current, and power factor with high accuracy. These meters give a real-time view of how energy consumption changes across machines or departments, especially when linked with a plc panel for load monitoring. - IoT Sensors

Sensors monitor temperature, vibration, airflow, and motor load, forming the core of IoT device management inside factories. These lightweight sensors require minimal wiring and rely on IoT connectivity for accurate, continuous data transfer. - VFD Panels

Variable Frequency Drives reduce energy use by controlling motor speed. When connected to an EMS, they provide insights into motor efficiency and load variations. - Data Loggers

These devices record energy data over time. Engineers can compare historical usage and spot patterns or anomalies. - PLC / SCADA Integration

EMS connects with PLCs and SCADA systems to collect machine behaviour and energy consumption trends. Integration of scada in iot and PLC logic allows engineers to correlate operational events, detect overloads, and improve process control. - Energy Dashboards

Dashboards provide graphical charts and visual indicators. This helps even non-technical users understand which areas need attention. - Alerts & Reports

EMS sends automated alerts when abnormal energy usage is detected. Reports help in audits, compliance, and decision-making. - Load Analysis Tools

These tools identify peak load times, connected loads, and critical machines that affect energy bills.

This combination helps factories transform raw electrical data into meaningful insights that uncover leakages, inefficiencies, and preventable machine failures.

Why an Energy Management System Matters in 2025

Factories must deal with challenges that make energy optimization unavoidable:

- Higher electricity tariffs

Power bills are increasing every year, pushing factories to find smarter ways to cut costs. EMS ensures energy is used only where needed. - Dynamic power loads in automated machines

Modern machines have fluctuating power demands. EMS helps track these variations and maintain stability. - Complex production lines

With interconnected processes, even a small energy spike can disrupt operations. EMS maintains consistency. - Increase in IoT-based devices

More data means better insights – EMS uses this data effectively. - Pressure for sustainability and net-zero

Industries must now meet strict environmental standards. EMS helps track emissions and reduce wastage. - Competition requiring cost reduction

Lower energy usage directly improves profitability, giving factories a competitive advantage.

How an Energy Management System Works Inside a Modern Factory

In a typical 2025 factory, EMS becomes a digital layer sitting above machinery. Its workflow looks like this:

1. Data Collection

Sensors and meters collect real-time machine data such as:

- Voltage – to check supply stability.

- Current – to measure load.

- Power Factor – to identify inefficiencies.

- Load – to avoid overload conditions.

- Harmonics – which can damage equipment.

- Motor efficiency – to prevent failures.

- VFD frequency and consumption – to optimize motor speed.

- Machine runtime – to detect idle operations.

This raw data helps engineers understand exactly how each part of the factory consumes power.

2. Data Processing

Collected data is processed using algorithms that detect load variations, imbalances, and abnormalities. The platform also identifies hidden losses in mcc panel components, motors, and drives.

The EMS software analyses this data to create:

- Live dashboards

- Machine-wise usage

- Department-wise consumption

- Trend charts

- Predictive analytics

3. Visualization

Dashboards convert data into charts and visuals. Engineers can see:

- Real-time consumption

- Department-wise usage

- Day-wise and shift-wise patterns

- Machine-wise energy breakdown

This makes decision-making faster and more accurate.

4. Alerts & Recommendations

EMS generates alerts when:

- Power factor drops below safe limits

- A motor consumes more energy than expected

- A VFD panel bypasses the drive

- Voltage fluctuates

- Machines run idle

EMS also evaluates how scada protocols in iot are performing across critical loads.

5. Optimization

Based on insights, factories can:

- Adjust machine schedules

- Improve vfd programming

- Reduce idle consumption

- Maintain power factor

- Balance loads

- Improve production health

Key Benefits of Energy Management Systems in 2025 Factories

1. Reduction in Electricity Costs

EMS reveals hidden inefficiencies. Factories commonly save 10% to 35% after installation. Savings come from:

- Reducing idle loads

- Preventing unnecessary consumption

- Optimizing peak-hour usage

- Improving power factor

- Using VFDs effectively

2. Improved Machine Performance

Improper load balancing or poor calibration in motors leads to excess energy use. EMS helps fine-tune systems integrated with the plc electrical panel and MCC units, improving machine health.

3. Real-Time Monitoring

Factories can see:

- Which machine consumes the most

- Which shift is inefficient

- Which process creates the biggest load

This data helps managers improve planning.

4. Preventing Downtime

EMS identifies abnormalities in motors, compressors, chillers, and pumps. Early detection prevents breakdowns and saves repair costs.

5. Better Power Quality

EMS improves overall electrical health by keeping power factor high and harmonics low. This reduces transformer stress and improves equipment life.

6. Data-Driven Decision Making

Managers can use actual consumption and load patterns to make better decisions. Data from iot device management and PLC-SCADA systems makes reporting smooth.

7. Compliance & Sustainability

Factories aiming for green manufacturing and ESG reporting need reliable energy data. EMS generates this automatically.

Industries following:

- ISO 50001

- ISO 14001

- Smart factory initiatives

- ESG reporting

benefit immensely from structured EMS data.

Common Problems EMS Helps Fix (Real Examples)

1. Motors Running Idle

EMS identifies machines running without load-common in conveyors, mixers, and HVAC systems.

2. Hidden Compressor Leakages

Compressed air is expensive. EMS patterns show abnormal compressor load cycles.

3. Voltage Imbalance in Panels

Continuous monitoring ensures MCC and mcc panel components remain stable.

4. Oversized Pumps & Motors

EMS helps detect when motors are operating below their optimal efficiency point.

5. Excessive Harmonics from VFD Machines

High harmonics reduce power quality and affect nearby equipment. EMS identifies THD issues quickly.

Applications of EMS in Modern Factories

1. Manufacturing Plants

EMS monitors CNC machines, conveyors, furnaces, and assembly lines. Managers can quickly identify energy-heavy sections and optimize them.

2. Process Industries

Chemical, pharmaceutical, and food industries use EMS for:

- Temperature regulation

- Motor load monitoring

- Reducing wastage

- Maintaining consistent production speed

3. Heavy Industries

Industries like steel and cement rely heavily on motors. EMS ensures balanced loading and reduced stress on motor systems.

4. Utility Monitoring

Utilities such as HVAC systems, compressors, chillers, and pumps consume massive energy. EMS keeps them efficient and prevents unnecessary runtime.

5. Multi-Plant Enterprises

Large companies with multiple factories can compare performance and adopt the best practices across all units.

The Role of IoT in EMS (2025 Update)

IoT has transformed EMS by introducing:

- Wireless data collection – easier installation, better accuracy

- Edge computing – faster processing and instant alerts

- Remote access – engineers can monitor factories from anywhere

- Predictive insights – identifying failures before they occur

- Plant-wide coverage – no need for manual meter readings

Using iot connectivity and iot enabling technologies, factories gain instant visibility. The integration of scada in iot ensures seamless communication between sensors and control systems. Predictive maintenance is now possible as IoT sensors detect vibration, heat rise, load imbalance, and harmonic distortion.

EMS + VFD = The Perfect Combination

VFDs reduce energy consumption by adjusting motor speed. When paired with an EMS:

- Motors run at optimal efficiency

- Harmonics are monitored

- Energy spikes are detected

- Load balancing becomes easier

- Drive bypass issues are prevented

This combination saves 20–40% energy, especially in large plants.

Challenges Without EMS in 2025

Factories without an EMS typically face:

- High energy bills

- Unexpected breakdowns

- Poor electrical health

- Load imbalances

- Harmonics issues

- No shift-wise visibility

- Increased downtime

Without real-time data, factories cannot optimize their operations.

Future of EMS: What 2025 and Beyond Looks Like

EMS in the future will use:

- AI-based optimization

- Automated control

- Digital twins

- Predictive maintenance

- Self-correcting systems

Factories that adopt EMS early will gain a clear advantage in cost, efficiency, and sustainability.

Conclusion

Energy Management Systems are now a necessity for modern factories. With increasing automation, IoT integration, and rising energy costs, industries need systems that offer real-time monitoring, predictive analytics, and deeper electrical insights. EMS-combined with PLCs, MCC panels, SCADA, VFDs, and IoT-helps factories create efficient, safe, and sustainable operations. As India moves towards smarter manufacturing, a powerful smart energy management system will be the backbone of future-ready industrial growth.