Modern water and wastewater plants handle enormous pressure-rising urban demand, strict environmental regulations, and the constant need for uninterrupted, safe water distribution. As these systems grow more complex, relying on manual monitoring or outdated relay logic is no longer practical. Industries, municipal corporations, and treatment facilities now depend on PLC-based automation to maintain accuracy, efficiency, and reliability across the entire water management cycle, powered by advanced Industrial PLC architecture.This shift has made PLC in wastewater treatment a critical part of modern infrastructure planning, especially as cities struggle to manage growing effluent loads.

Programmable Logic Controllers (PLCs) have become the backbone of smart water infrastructure. Whether it’s controlling pumps, monitoring tank levels, operating chemical dosing systems, or ensuring precise filtration sequences, PLCs allow operators to manage critical processes with real-time intelligence. These automated functions are typically organized inside a robust PLC electrical panel built for industrial environments.

What Is PLC Control in Water and Waste Systems?

A PLC is an industrial computer that receives data from sensors, processes logic, and controls mechanical/electrical devices.These systems are often designed by trusted Programmable Logic Controller manufacturers who build hardware capable of withstanding harsh conditions, which is especially important for PLC in Wastewater Treatment where moisture, gases, and variable loads are common.

In water treatment systems, PLCs manage everything from pumps to valves to chemical dosing while communicating through optimized PLC control panel components for safe and reliable automation.

- Monitoring critical parameters

PLCs continuously collect data such as tank levels, pH, turbidity, pressure, and flow rate.

This real-time monitoring is usually visualized using modern SCADA software, giving operators complete insights into plant performance and helping them fine-tune PLC in Wastewater Treatment based on actual process conditions rather than guesswork. - Controlling pumps, motors, and valves

Instead of manually starting or stopping equipment, the PLC automatically runs pumps and valves based on the logic conditions. functioning like a dedicated Motor control center for the entire treatment plant.

This prevents mistakes and ensures the plant follows the correct operating sequence. - Managing filtration and treatment cycles

PLCs activate filtration, backwash cycles, aeration stages, and sludge treatment with logic written using standard PLC programming languages for precise steps.

This keeps the treatment process stable and avoids deviations in water quality. - Ensuring safe and regulated discharge

Wastewater must meet quality standards before release.

The PLC checks water parameters continuously and prevents the system from discharging untreated or unsafe water.

PLC systems integrate seamlessly with remote dashboards using HMI SCADA PLC configurations for superior monitoring and decision-making.

Key Processes Automated by PLCs in Water & Wastewater Plants

Using PLCs, several critical stages of water/wastewater treatment can be fully automated:

- Raw Water Intake & Screening – Controlling pumps, inlet valves, and screens to manage variable inflow, prevent debris ingress.

- Pumping & Distribution Networks – Automated pump sequencing, lead/lag control, pressure/flow regulation for consistent water supply.

- Chemical Dosing & pH / Chlorine / Coagulant Control – Real-time monitoring (pH, turbidity, chlorine residual) via sensors; automatic dosing to ensure safe disinfection and compliance.

- Coagulation, Flocculation, Sedimentation & Filtration – Automating mixing, settling and filtration sequences; enabling backwash cycles, filter cleaning – all timed and controlled for optimal efficiency.

- Disinfection (Chlorination / UV / Ozone / Chemical) – Ensuring correct dosing and contact time, based on flow and water quality sensors.

- Sludge Handling & Wastewater Treatment – Automated control of sludge pumps, clarifiers, aeration basins, sludge thickening, dewatering – improving reliability and safety while reducing manual intervention.

- Monitoring & Reporting – Continuous logging of key parameters (flow, turbidity, pH, chemical usage, pump runtime), alarms for anomalies, data for regulatory compliance & audit trails.

In sludge and biological systems, PLC in Wastewater Treatment plays a major role in controlling pumps, aeration blowers, clarifiers, and sludge recycling.

Why PLC Control Is Essential in Water & Waste Management

1. Accurate Process Sequencing

Every treatment process—coagulation, aeration, sedimentation, filtration—must follow strict timing. PLCs handle this perfectly using advanced logic, ensuring stable operation through modern PLC technology.

- Coagulation and Flocculation: The PLC maintains correct mixing speed and chemical dosage to form flocs properly.

- Sedimentation: It controls scraper motors and sludge removal timing to prevent overflow.

- Filtration: It runs filters for the right duration and triggers backwash when turbidity rises.

- Disinfection: Chemical dosing pumps operate only when required, preventing excess chlorine or under-dosing.

A PLC executes these sequences automatically, ensuring consistency and minimizing human error.

2. Real-Time Monitoring and Control

With sensors feeding continuous data into the PLC, operators can track:

- pH and Turbidity Monitoring

If pH becomes too acidic/alkaline or if turbidity increases, the PLC adjusts dosing or initiates filtration to correct it before quality drops. - Flow and Pressure Monitoring

Sudden pressure spikes can damage pipes, while low pressure affects supply.

PLCs stabilize the system by automatically reducing pump speed or opening/closing valves. - Dissolved Oxygen (DO) Control

In biological treatment, low DO harms microorganisms.

PLCs increase blower output to maintain aeration efficiency. - Tank Level Control

Overflows waste water and damage equipment; dry-running destroys pumps.

PLCs intelligently maintain safe tank levels at all times.

Any abnormal reading triggers automated corrective actions or alarms.

3. Energy Efficiency

Pump operation is one of the biggest power consumers in water facilities. PLCs optimize:

- Optimized Pump Operation

Instead of running constantly, pumps operate only when necessary, based on real-time level and pressure data. - VFD Integration

PLCs adjust pump speed with VFDs so motors don’t run at full power all the time.

This cuts energy usage by 20–40%. - Alternate Pump Running

PLCs rotate pumps automatically to distribute load, extending equipment life and reducing energy spikes. - Peak Load Management

In facilities that operate multiple heavy motors, PLCs shift certain operations to off-peak hours, lowering electricity bills.

This reduces electricity usage significantly.

4. Safety and Compliance

PLCs help facilities meet safety and environmental guidelines by ensuring:

- Correct disinfection levels

- Safe chemical handling

- Proper wastewater discharge standards

- Continuous process logging

This makes PLC in Wastewater Treatment crucial for meeting environmental regulations.

How PLC Control Works in Water and Waste Systems

1. Input Collection

Sensors placed throughout the system measure:

- Level (ultrasonic, float, radar)

- Pressure

- Flow

- Chemical concentration

- Oxygen levels

This sensor data also supports future integration with iot system management with netconf yang for smarter networks.

2. Logic Execution

Based on programmed instructions:

- Pumps start/stop

- Valves open/close

- Blowers adjust airflow

- Dosing pumps deliver chemicals

- Filtration cycles activate automatically

3. Output Control

The PLC sends signals to actuators, relays, and VFDs to control field devices with precise timing.

Based on logic, the PLC sends output signals to:

- Pumps

- Valves

- Motors

- VFDs

- Dosing systems

- Blowers

- Solenoid-operated actuators

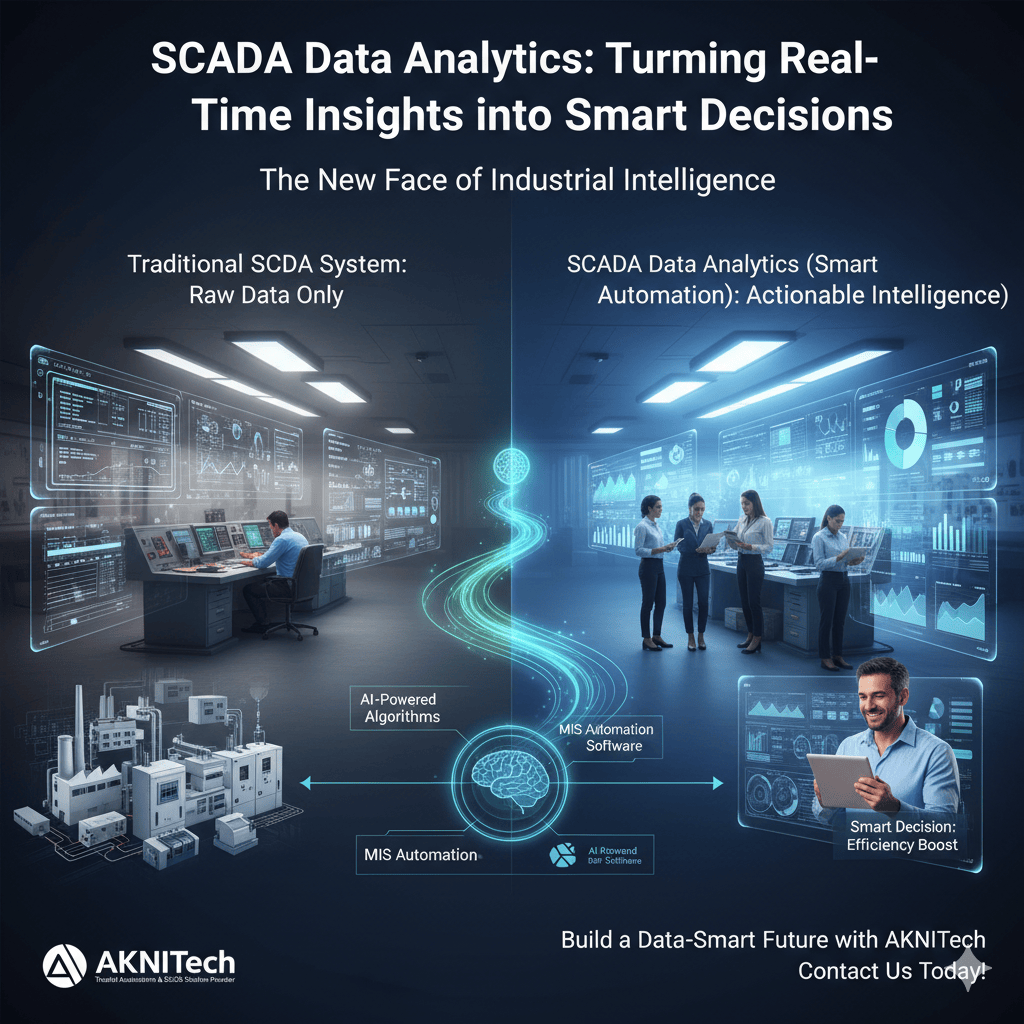

4. SCADA Integration

Most modern plants use PLC + SCADA together for:

- Real-time dashboards

- Alarm history

- Trend analysis

- Remote operation

- Reporting and audit trails

Applications of PLCs in Water & Waste Management

1. Water Treatment Plants (WTP)

- Raw water intake control

- Clarifier automation

- Filter run and backwash cycles

- Chlorination and dosing

This ensures stable and safe drinking water production.

2. Sewage Treatment Plants (STP)

- Aeration control

- Sludge handling

- Blower management

- Effluent quality monitoring

This ensures regulatory compliance.

3. Industrial Effluent Treatment Plants (ETP)

- pH neutralization

- Chemical dosing systems

- Multi-stage treatment automation

This ensures safe disposal and environmental compliance.

4. Pumping Stations / Distribution

- Booster pump control

- Pressure monitoring

- Reservoir level management

This keeps urban water supply stable and uninterrupted.

5. RO and Desalination Systems

- Pressure control via VFD

- Membrane flush sequences

- Conductivity monitoring

This guarantees consistent purified water output.

Benefits of PLC-Based Automation in Water Systems

- Consistent Water Quality & Process Stability

With real-time feedback from sensors and automatic control logic, water parameters (flow, pH, chlorine residual, turbidity) remain within safe thresholds – ensuring consistent water quality. Human errors – dosing mistakes or timing lapses – are eliminated. - Reduced Labour & Manual Intervention

Manual control of valves, pumps, dosing is labour-intensive and prone to error. With PLC automation, operations run automatically – reducing manpower needs, human fatigue, and risk of mistakes. - Energy & Resource Optimization

Pumps, aeration motors, chemical dosing – all can be controlled smartly based on demand, flow, water quality. This leads to significant savings in power, chemicals, maintenance, and extends equipment lifespan. - Remote Monitoring, Data Logging, Compliance & Safety

With integration of SCADA / HMI, plant operators can monitor plant status, respond to alarms, and access logs – often remotely. This helps in regulatory compliance, audit trails, and quick response to emergencies. - Scalability & Flexibility

PLCs are modular – they can be scaled to small pumping stations or large municipal/industrial treatment plants. As demand grows, the control logic or I/O can be expanded. This flexibility makes PLC-based systems future-proof. - Reliability, Accuracy & Repeatability

Industrial-grade PLC hardware ensures uninterrupted operations in harsh environments (moisture, dust, temperature). Together with programmatic logic, this ensures high reliability and precise control cycles.

How AKNITech Supports Water & Waste Management Automation

AKNITech has extensive experience delivering automation and control solutions for:

- STP/ETP plants

- Industrial wastewater treatment

- Water filtration systems

- Pumping stations

- RO plants

- Smart utility monitoring

Our expertise includes:

- PLC Programming

We work with Siemens, Delta, Mitsubishi, Schneider and others, making us a trusted industry-ready plc company for water automation. - SCADA Visualization

Custom dashboards give operators full clarity and control over their plant. - VFD & Motor Control Integration

Energy-efficient pump and blower operation with advanced protection. - Smart Panel Design

We build durable, industry-grade PLC panels with safety, reliability, and long-term performance in mind. - Retrofitting Old Systems

We replace outdated relay logic and old PLCs with modern automation for better efficiency. - Remote Monitoring Solutions

Supervisors can track plant performance from anywhere using SCADA and cloud tools.

Our expertise makes AKNITech a trusted partner for PLC in Wastewater Treatment and water automation projects across India.

Conclusion

PLC-based automation has transformed how modern water and wastewater systems operate. By enabling precise control, faster decision-making, and reliable treatment processes, PLCs ensure plants meet safety, quality, and energy goals without interruption. As water demand increases and environmental norms tighten across India, adopting PLC automation is no longer a choice-it’s a necessity.Designed with high-grade wiring and components using optimized plc panel components for long-term reliability.