PLC Control Panels are the foundation of modern industrial automation. These systems simplify complex operations, increase safety, and boost productivity across various sectors. From manufacturing to water treatment, PLCs ensure that every machine and process runs smoothly and efficiently.

As industries evolve toward smart automation, companies like AKNITech continue to design and deliver intelligent PLC-based solutions that improve performance and reliability.

What Are PLC Control Panels?

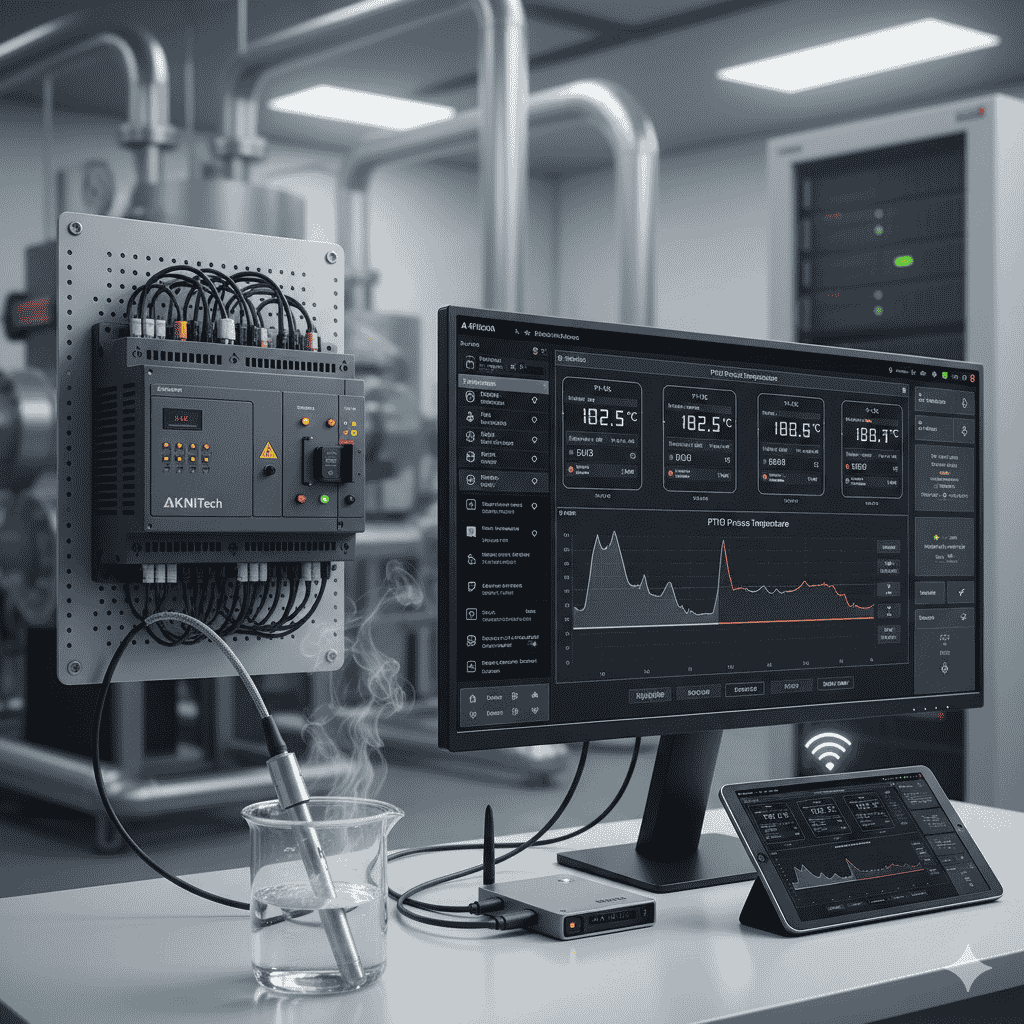

A PLC Control Panel is an electrical unit that houses the programmable logic controller, along with relays, contactors, and circuit breakers. It connects sensors, actuators, and motors to the main controller, allowing for precise and automated operation.

Through programmed logic, these panels continuously monitor inputs, make decisions, and trigger outputs – call within milliseconds. They are used to control everything from conveyor belts to power distribution systems.

Industrial Applications of PLC Control Panels

PLC Control Panels are vital in industries where accuracy, timing, and safety are crucial. Below are some major industrial applications where these panels play a central role.

Manufacturing and Assembly Automation

Manufacturing plants rely heavily on PLC Control Panels to coordinate robotic arms, conveyors, and machine tools. They ensure perfect synchronization between machines, enabling continuous production with minimal human intervention.

For example, automobile factories use PLCs to manage robotic welding, painting, and assembly lines, maintaining consistency and reducing production errors.

Water and Wastewater Management

In water treatment plants, PLC systems control pumps, valves, and chemical dosing mechanisms. These panels help monitor pressure, flow rate, and pH levels, ensuring clean water supply and efficient wastewater treatment.

They also send alerts if any system operates outside safe limits, allowing engineers to prevent failures quickly.

Power Generation and Distribution

Power stations and substations use PLC Control Panels to manage turbines, circuit breakers, and load distribution. They automatically adjust power output based on demand, preventing overloads and energy loss.

In renewable energy plants, PLCs help synchronize solar and wind power systems with the main grid for efficient energy conversion.

Food and Beverage Industry

Automation has transformed the food industry. PLCs manage temperature, mixing speed, filling, and packaging lines to maintain hygiene and consistency.

For instance, PLC panels regulate the temperature in ovens and the flow of liquid in bottling machines, ensuring that every batch meets the same high-quality standards.

Oil, Gas, and Petrochemical Plants

In these high-risk environments, PLCs play a critical role in safety and process control. They monitor pressure, temperature, and flow in real time, automatically triggering safety protocols when abnormal conditions occur.

By integrating PLCs with SCADA systems, operators can monitor large-scale processes remotely and respond instantly to faults.

HVAC and Building Automation

Smart buildings use PLC Control Panels to manage HVAC systems, lighting, and power distribution. These systems automatically regulate temperature and lighting based on occupancy, saving energy and improving comfort.

Many large facilities and smart campuses now rely on PLC-based building automation for cost-effective, centralized control.

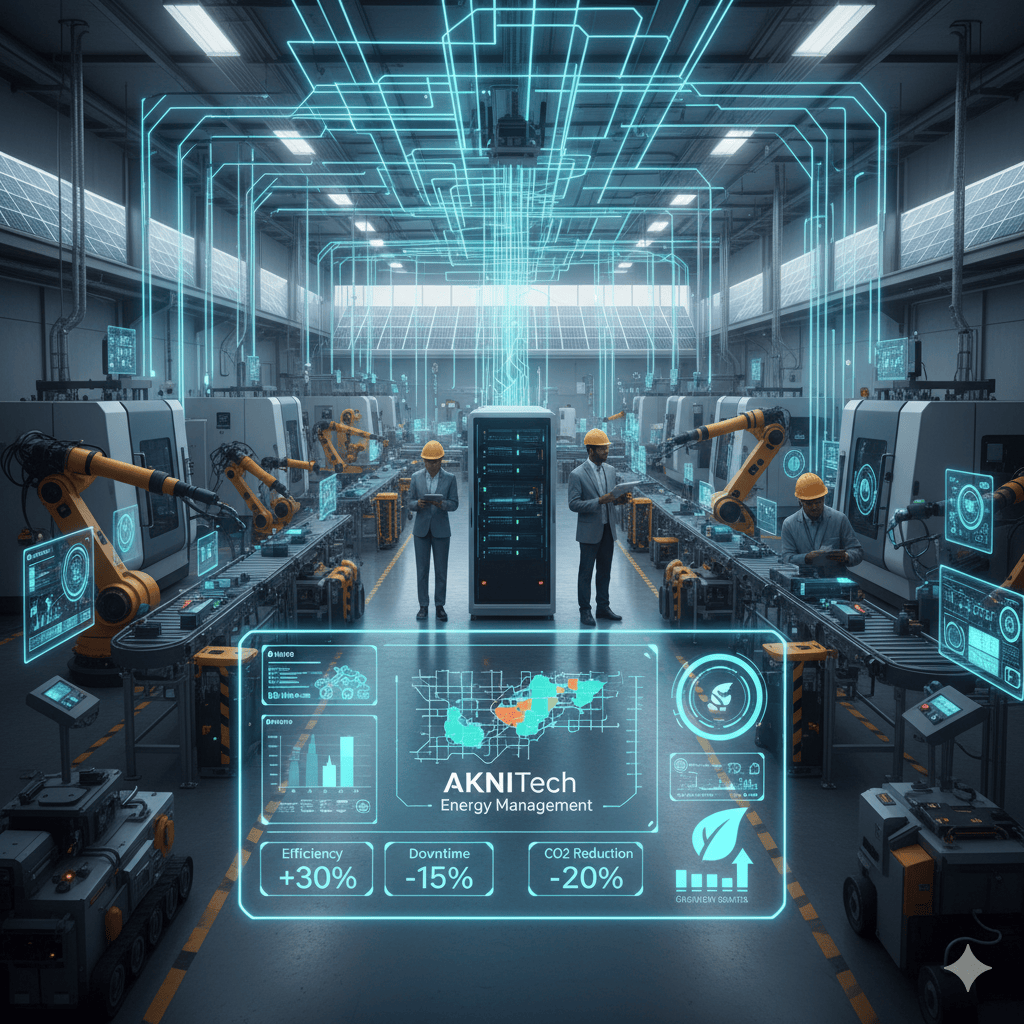

The Role of AKNITech in PLC Automation

AKNITech, based in Bhopal, is a trusted name in industrial automation and PLC Control Panel design.

The company offers customized solutions that integrate PLC, SCADA, and IoT technologies for a complete automation ecosystem.

With a focus on efficiency, safety, and innovation, AKNITech’s PLC systems help industries achieve real-time control, data accuracy, and long-term reliability.

Benefits of Using PLC Control Panels

High Efficiency: PLCs automate repetitive tasks, saving time and labor.

Enhanced Safety: Immediate fault detection and automatic shutdown prevent equipment damage.

Scalability: Easy to upgrade as industrial processes expand.

Integration: Connects with IoT and SCADA systems for complete digital control.

Cost Reduction: Lower downtime and energy waste increase profitability.

Future Trends in PLC Automation

The future of PLC Control Panels lies in digital connectivity and intelligent analytics. With the rise of Industrial IoT (IIoT), modern PLCs are becoming smarter, faster, and more data-driven.

Artificial intelligence and machine learning will soon enhance PLC logic, allowing predictive maintenance and real-time optimization across entire facilities.

As automation grows, PLCs will remain the backbone of connected, energy-efficient industries.

Frequently Asked Questions (FAQs)

1. What is the main function of a PLC Control Panel?

A PLC Control Panel automates machinery and processes by receiving inputs, executing logic, and sending outputs to control devices.

2. How are PLC Control Panels used in industries?

They manage production lines, monitor power systems, and control processes in sectors like manufacturing, energy, and water treatment.

3. Can PLCs be connected to IoT systems?

Yes. IoT integration allows remote monitoring, data collection, and predictive maintenance for industrial systems.

4. How does AKNITech customize PLC panels?

AKNITech designs panels based on client requirements – integrating PLC, SCADA, and IoT for smarter automation.

5. Why are PLCs better than manual control systems?

They reduce human error, ensure consistent output, and enable 24/7 operation with minimal supervision.

PLC Control Panels are at the heart of industrial automation, powering everything from small machines to large-scale systems.

As industries shift toward digital transformation, PLCs continue to provide unmatched precision, control, and safety.

AKNITech’s automation solutions help industries harness the full potential of PLC technology to build smarter, safer, and more productive operations.

Looking to modernize your factory or process systems?

Contact AKNITech today to explore custom PLC Control Panels built for your industry’s unique needs.