In today’s industrial world, automation is no longer optional – it’s essential. At the heart of this transformation is the Programmable Logic Controller (PLC), a robust device that controls machines, optimizes processes, and ensures efficiency across industries. From production lines to smart energy grids, the applications of PLC in industry are endless.

This guide explores the top 10 PLC applications spanning manufacturing to energy management, while showing why PLC panels, SCADA in IoT, and process automation are shaping the factories of tomorrow.

What is a PLC and Why It Matters in Industry?

A PLC (Programmable Logic Controller) is an industrial digital computer used to control machinery and processes. Unlike traditional relays or timers, PLCs are flexible, programmable, and scalable, making them the backbone of modern automation.

- PLC automation ensures accuracy and reliability.

- A PLC control panel or PLC electrical panel integrates hardware and software for real-time operations.

- Industries use PLC programming languages like Ladder Logic or Structured Text to customize functions.

Top 10 Applications of PLC in Industry

1. Manufacturing Automation

PLCs are widely used in assembly lines, packaging, and robotic arms. They control everything from conveyor belts to robotic welding, reducing downtime and ensuring consistency.

Example: Automobile manufacturers rely on industrial PLCs for welding robots and painting booths.

2. Process Automation (Food, Pharma, Chemicals)

Industries like food processing, pharmaceuticals, and chemical plants use PLCs to control pumps, mixers, and conveyors.

In process automation in Bhopal, PLC systems are helping local manufacturers reduce waste and improve quality.

3. Energy Management Systems

One of the fastest-growing applications of PLC is in energy management. PLC panels control smart grids, renewable energy integration, and turbine operations in power plants.

Importance of energy management: Lower costs and reduce carbon footprint while increasing efficiency.

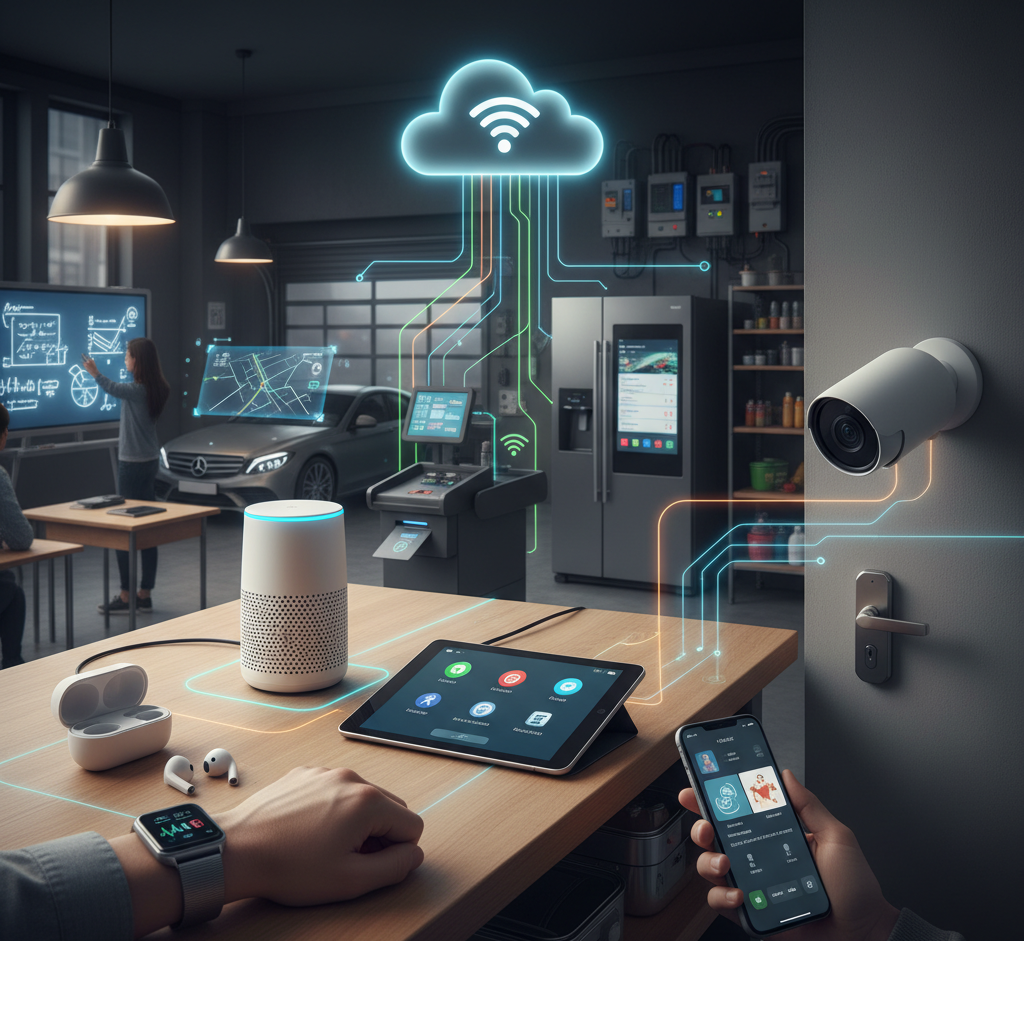

4. SCADA and IoT Integration

PLCs integrate seamlessly with SCADA in IoT systems to enable remote monitoring, predictive maintenance, and real-time data analytics.

Example: IoT monitoring devices combined with PLCs allow factory managers to track performance from anywhere.

5. Automobile Industry Applications

From painting robots to conveyor-driven assembly lines, PLCs make the auto industry highly efficient. Vehicle safety tests, automated welding, and precision painting all depend on PLC automation.

6. Water Treatment & Smart Irrigation

PLCs ensure precise control in municipal water treatment plants and irrigation systems.

Example: Smart irrigation systems in India use PLC + IoT for water conservation in agriculture.

7. HVAC and Building Automation

In commercial buildings, PLCs manage heating, ventilation, and air conditioning (HVAC). They ensure comfort, energy efficiency, and reduce manual interventions.

8. Mining and Heavy Machinery

Mining operations involve massive machinery that requires safe and precise control. PLCs monitor conveyor belts, crushers, and ventilation systems, ensuring safety in high-risk environments.

9. Power Plants and Energy Sector

From thermal to hydro and renewable energy, PLCs control turbines, boilers, and safety systems.

Example: In India, power plants deploy PLC electrical panels to manage heavy electrical loads efficiently.

10. MIS and Data-Driven Automation

Modern industries rely on MIS panels and data-driven systems. PLCs provide real-time data to Management Information Systems, enabling smarter decisions and reduced downtime.

Benefits of Using PLC Across Industries

- Flexibility: Easily reprogrammed for new tasks.

- Reliability: Withstand harsh industrial conditions.

- Efficiency: Reduce manual work and improve accuracy.

- Scalability: Can be expanded with PLC panel components and IoT integration.

This is why working with a trusted PLC manufacturing company is critical for long-term industrial growth.

Future of PLC in Industry (2025 and Beyond)

As industries adopt IoT device management and smart sensors, PLCs will become even more advanced:

- Integration with AI for predictive maintenance.

- Energy optimization through smart grids.

- Seamless connectivity with plc manufacturers in India leading global exports.

Driving Smarter Industries with PLC Solutions

The applications of PLC in industry show how this technology powers everything – from manufacturing automation to energy efficiency. For businesses in India and beyond, PLC systems are no longer a choice, they’re a necessity.

Looking for reliable PLC panels, electrical panels, or process automation in Bhopal?

AKNItech provides industrial PLC solutions, SCADA design, and energy management systems that keep your operations efficient and future-ready.