In today’s rapidly evolving industrial world, Smart PLC Electrical Panel play a vital role in modern automation, making processes more efficient, safe, and reliable. At the heart of this transformation lies the PLC electrical panel, a vital component that brings intelligence, efficiency, and precision to industrial processes.

But what exactly goes inside a smart PLC electrical panel? In this article, we’ll take you behind the scenes and explore the essential components, how they work together, and why they’re critical for modern factories and industries.

What is a PLC Electrical Panel?

A PLC (Programmable Logic Controller) electrical panel is the control center for industrial automation. It houses the brain of your operations, combining electrical and control components that manage machines, motors, sensors, and entire production lines.

Unlike traditional relay-based panels, a smart PLC panel is:

- Programmable: Easily reconfigured for different tasks or processes.

- Scalable: Designed to grow as your plant expands.

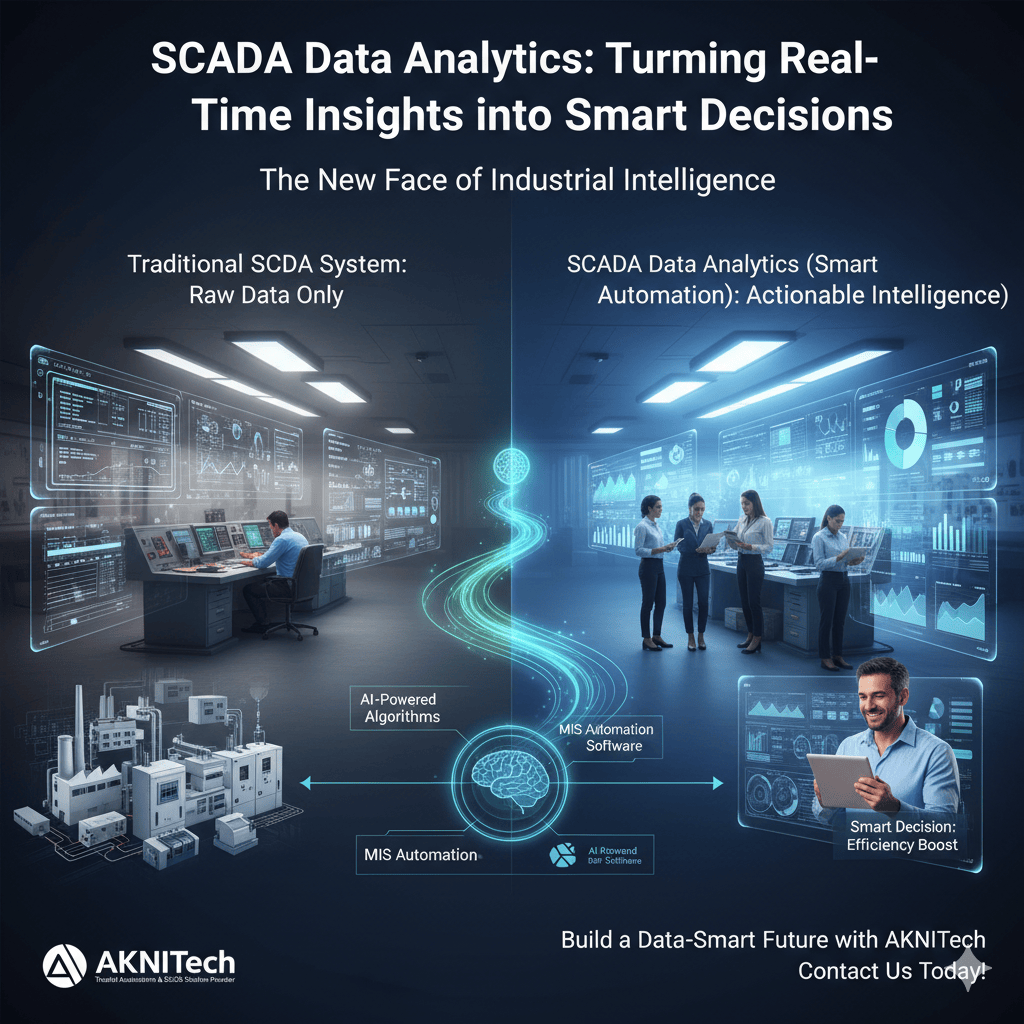

- Connected: Integrates seamlessly with SCADA systems and IoT devices for real-time monitoring and remote control.

At Aknitech, we design and manufacture custom PLC control panels in Bhopal, delivering advanced automation solutions for industries across India.

Key Components Inside a Smart PLC Electrical Panel

A smart PLC panel is made up of two primary sections – Power Components and Control & Logic Components. Each plays a unique role in keeping industrial processes running smoothly.

A. Power Components: Managing Electricity Flow

The power section ensures safe, stable, and reliable energy delivery to the control devices and machines.

1. Main Circuit Breaker

The first line of defense, protecting the entire system from overloads and short circuits.

2. Transformer

Steps down incoming high voltage to a lower, safer voltage suitable for control devices.

3. Power Supply Unit

Converts AC (alternating current) into DC (direct current), providing stable power to sensitive electronics like PLC CPUs and sensors.

4. VFD (Variable Frequency Drive)

- Controls motor speed and torque.

- Improves energy efficiency.

- Protects motors from sudden starts and stops.

5. Soft Starter

- Provides smooth motor startup.

- Reduces mechanical stress and electrical surges.

- Ideal for heavy-duty machines.

Pro Tip: Choosing between a VFD vs soft starter depends on your specific motor control needs. Aknitech experts can help you select the right solution.

Control & Logic Components: The “Brain” of Automation

These components are responsible for processing information, running programs, and controlling the outputs.

1. PLC CPU (Central Processing Unit)

The heart of the system, where all automation logic is executed.

- Processes data from sensors (inputs).

- Executes programmed instructions.

- Sends commands to actuators (outputs).

2. I/O (Input/Output) Modules

- Input modules receive signals from sensors like temperature probes or limit switches.

- Output modules send signals to devices like motors, pumps, and alarms.

3. HMI (Human Machine Interface)

The user interface that allows operators to:

- Monitor real-time data.

- Control processes directly.

- Troubleshoot issues quickly.

4. Communication Modules (SCADA Integration)

These allow the PLC to connect with SCADA systems or IoT networks, enabling remote monitoring and predictive maintenance.

5. Relays and Contactors

Act as switches that control high-power devices safely.

How It All Works: The Flow of Automation

A smart PLC panel operates like a well-orchestrated team. Here’s a simple breakdown of how it works:

Step 1: Input Signals

Sensors detect data such as temperature, pressure, or flow rate and send signals to the PLC.

Step 2: Processing Logic

The PLC CPU processes the data using pre-programmed logic.

Step 3: Output Control

The PLC sends commands to output devices like motors, valves, or alarms.

Think of it as a digital brain, continuously monitoring and making split-second decisions to keep your production line running efficiently.

The Manufacturing Process of a Smart PLC Panel

At Aknitech, our PLC panel manufacturing process follows strict quality and safety standards to ensure top performance and longevity.

Step-by-Step Process:

- Requirements Gathering: Understanding client needs, input/output counts, and process goals.

- Electrical Design: Creating wiring diagrams and layout plans.

- Component Selection: Choosing high-quality parts like PLCs, VFDs, HMIs, and safety devices.

- Panel Assembly: Mounting components on DIN rails inside the enclosure.

- Wiring and Labeling: Organizing cables for easy maintenance and troubleshooting.

- Testing and Commissioning: Thorough quality checks before delivery and installation.

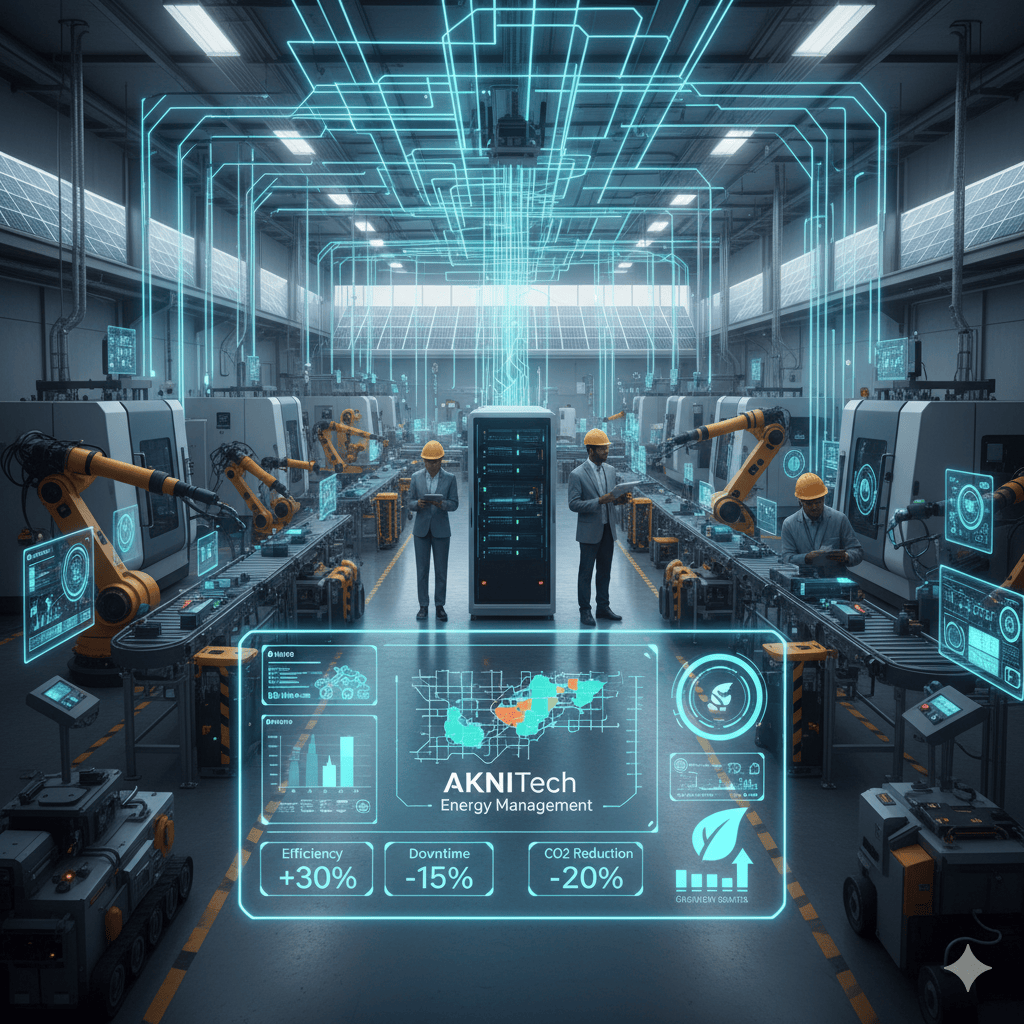

Applications of Smart PLC Panels

Smart PLC panels are used across a wide range of industries, including:

- Manufacturing Plants – Process automation and production line control.

- Water Treatment Facilities – Pump control and water flow management.

- Food & Beverage Industry – Quality control and packaging automation.

- Energy Sector – Power distribution and load management.

- Smart Factories – IoT-enabled remote monitoring and predictive maintenance.

Aknitech designs industry-specific solutions tailored to your exact operational needs.

Why Smart PLC Electrical Panels Are Essential for Modern Industries

Industries today are embracing Industry 4.0, where machines, sensors, and systems are interconnected through IoT and advanced automation.

A smart PLC panel:

- Provides real-time monitoring and control.

- Reduces downtime through predictive maintenance.

- Optimizes energy usage and machine efficiency.

- Enables remote access and cloud integration for decision-makers.

Partner with Aknitech for Your PLC Needs

When it comes to PLC control panel manufacturing, Aknitech delivers unmatched quality and expertise:

- Custom Design Solutions: Built for your exact industry requirements.

- Complete Lifecycle Support: From concept to installation and after-sales service.

- Expert Team: Skilled engineers specializing in PLC programming and SCADA integration.

- High-Quality Standards: Panels designed to meet IEC and UL guidelines.

Transform your industrial operations with precision and reliability.

Reach out to Aknitech today and take the first step toward smarter, more efficient automation.

Smart Automation Starts with a Smarter PLC Panel

A smart PLC electrical panel isn’t just a collection of components – it’s the heart of industrial automation. From managing power flow to enabling real-time decision-making, each element plays a crucial role in keeping operations seamless, safe, and future – ready.

Whether you need to upgrade outdated systems or build a new smart factory, Aknitech’s custom PLC panels ensure you’re ready to meet the challenges of Industry 4.0.