In today’s manufacturing environment, efficiency and automation are essential for maintaining a competitive edge. PLC automation, along with IoT device control systems, effectively manages complex operations, benefiting manufacturers with operational efficiency gains, cost reductions, and enhanced safety. At AKNItech, we specialize in tailored PLC automation and IoT systems that allow plants to run more effectively and successfully respond to the demands of contemporary industry.

What is PLC Automation?

Understanding how PLC Automation can be used to support manufacturing – PLC automation uses Programmable Logic Controllers (PLCs) to control machinery and industrial processes and equipment. When plants implement PLC industrial automation, they can automate repetitive tasks, increase the reliability of the system, and minimize human judgment and error. The manufacturers use PLC programming to confirm and verify that processes are performed correctly and that the PLC system is operating as intended.

AKNItech offers PLC programming services as a means to provide custom and efficient automation of the manufacturing process and operational reliability.

What is IoT Device Control and how does it Improve Manufacturing?

IoT device control in manufacturing uses IoT devices along with PLC systems for real-time data collection, monitoring, and control. PLC systems can enhance process management and decision making through receiving signals and generating control output from two new layers of intelligence: physical existence and real-time access to sensor and control network data, and enabling remote control of systems in an IoT framework.

AKNItech integrates IoT device management combined with our PLC to develop a complete control structure for smarter and more efficient manufacturing.

The Integration of PLC and IoT: A Winning Combination for Manufacturers

The combination of an IoT control system with a PLC automated system creates a strong solution for creating a complex manufacturing system. The PLC system automates tasks such as assembly of components, dosing of chemicals, or managing inventory, along with IoT devices that provide real-time data on your performance metrics, such as energy utilization, machine vendor health, or system efficiency.

At AKNItech, we integrate IoT devices with PLC automation technology to show our customers real-time data to make changes for smarter decision-making, reduce operational costs, and better utilization of resources.

How IoT Monitoring Adds to PLC Systems to Improve the Manufacturing Process

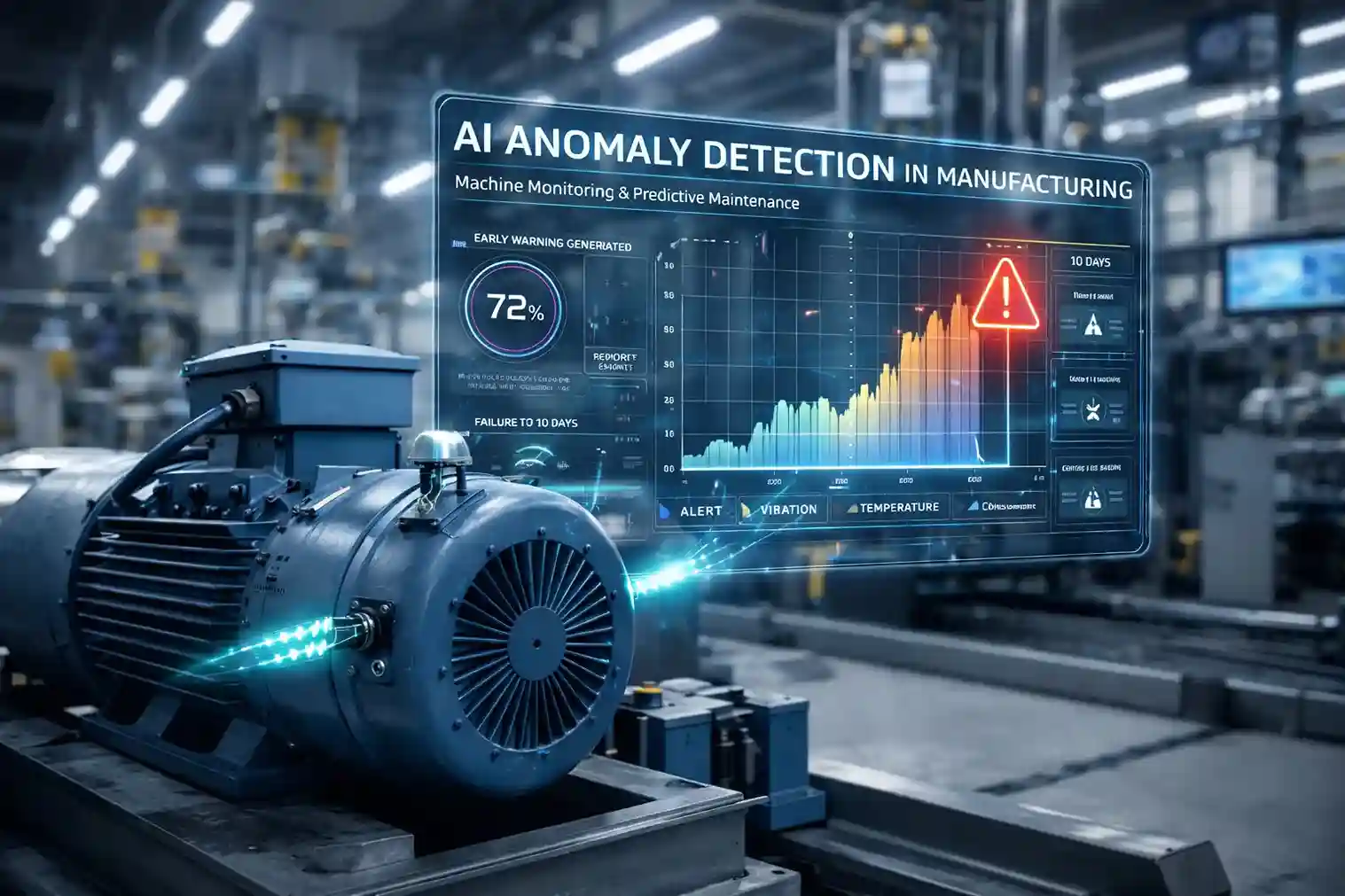

IoT monitoring adds a more intelligent focus to PLC systems. When sensors and devices are connected to the PLC system, they offer a monitoring and control function on a real-time basis, while the PLC also tracks, collects, and organizes the necessary data; this enhances the control over equipment and operations. The IoT controls can also automatically monitor and control processes such as inventory, quality control, or energy etc.

At AKNItech, we manage the integration of IoT Systems with PLC Devices. This maximizes the usefulness of the IoT device management protocol and completes a smarter and more efficient automation solution for the manufacturer. This integration can also improve your asset management and reduce equipment downtime.

Benefits of Integrated PLC and IoT for Greater Manufacturing Efficiency

Many ways to integrate PLC systems with IoT devices can streamline manufacturing:

- Better Automation: Certain tasks, like temperature regulation or chemical dose, can be automated, thus improving optimal performance.

- Real-time monitoring: IoT devices send data to the PLC, allowing manufacturers to act on the most up-to-date information.

- Predictive Maintenance: Using smart IoT sensors, plants can anticipate equipment failure and conduct maintenance before equipment fails.

- Cost Reduction: Automation and real-time adjustments reduce operational costs by reducing energy use and improving resource utilization.

AKNItech provides IoT and PLC-integrated systems that optimize these processes to make a plant run as efficiently as possible with minimal downtime.

The Future of PLC Automation and IoT in Manufacturing

As manufacturing plants become more complex, the need for smart automation and real-time data monitoring increases. The future of PLC automation lies in its continued integration with IoT systems. AKNItech is already leading the charge and helping plants move toward smart technology that will help improve safety, reduce energy consumption, and increase productivity.

What makes AKNItech’s PLC Programming Solutions Different?

PLC Programming is a component of industrial automation that ensures a PLC system runs flawlessly and provides superior automation. AKNItech provides PLC programming solutions and advanced solutions in PLC programming solutions, including SCADA PLC programming, which is a more advanced form of PLC programming. AKNItech offers delta PLC programming and HMI programming that can be developed and supplied based on your manufacturing needs.

Our experts provide a seamless integration of your PLC System and IoT monitoring devices and can provide intelligent automation at a lower cost. We also provide office tools for PLC Programming software that is customizable to the unique needs of your plant.

Why Use AKNItech for PLC Automation and IoT Integration?

AKNItech is the preferred choice for PLC programming and IoT system management. Our solutions are built for our clients’ unique needs so they will integrate seamlessly and function at the optimal performance level.

The Future of Manufacturing with PLC Automation and IoT

PLC automation and IoT device control systems are essential for modernizing manufacturing operations. They enable real-time data monitoring, smarter automation, and more efficient resource management. AKNItech provides tailored PLC and IoT solutions that help manufacturers boost efficiency, reduce downtime, and improve safety standards.

Contact AKNItech today to explore how our PLC programming and IoT integration can transform your manufacturing operations.