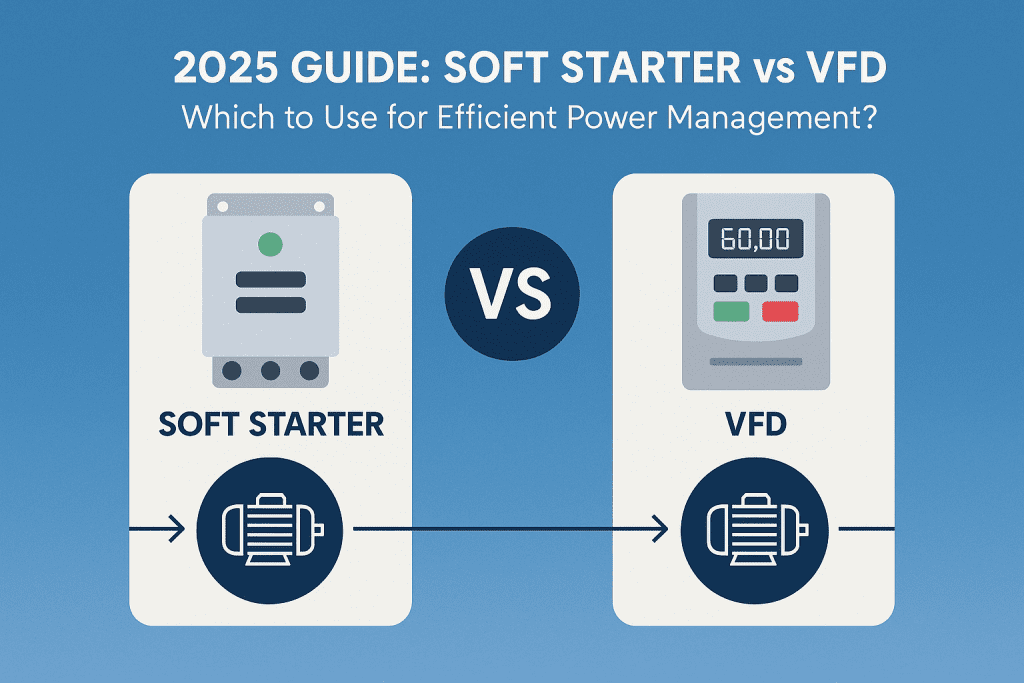

As we approach 2025, power management continues to be top of mind for industrial and commercial industries. In most applications, you utilize a Variable Frequency Drive (VFD) or Soft Starter as a method of controlling motor speed and improving energy efficiency. Which is best for your application and why? For this post, we’ll summarize the key differences between a VFD and a Soft Starter and how AKNItech can assist when installing and optimizing your energy management systems.

What is a VFD, and why for plant applications?

A VFD is a Variable Frequency Drive, which is a mechanism for varying the speed and torque of an electric motor by adjusting the frequency of the electrical power source to the motor. This working principle allows a motor to be run with efficiency, saving energy and prolonging the life of the equipment.

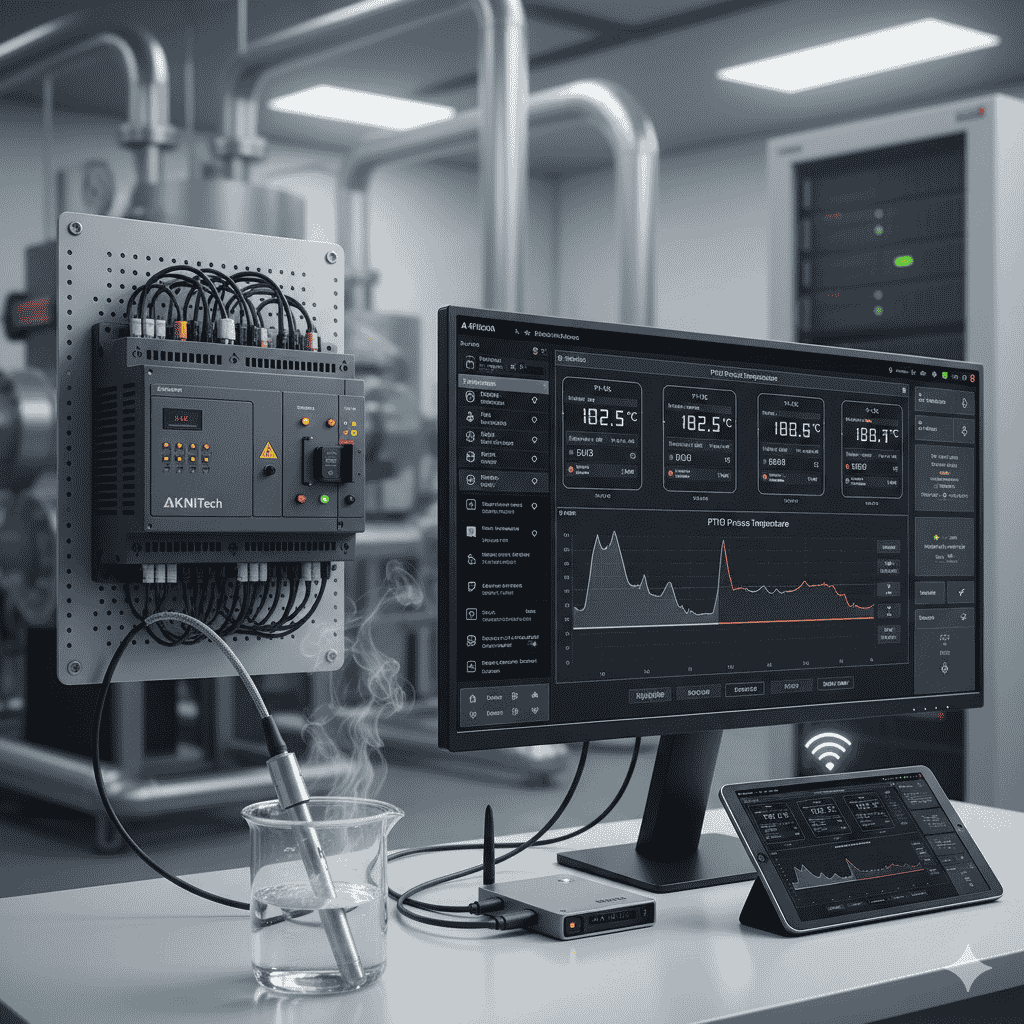

AKNItech has years of experience integrating systems and can provide a complete solution for any system integration requirements. The ability to control motor speed through VFD technology will achieve energy savings and better control of performance in machines.

Types of VFDs

There are many types of VFDs you can integrate into your motors. Examples include single-phase, three-phase , and undergo various power rating comparisons, and you can even use a solar VFD if you are someone who takes advantage of renewable energy applications. Each VFD circuit diagram provides the application to operate within varying motor configurations. AKNItech works with customers to realize their configured needs.

The benefits of VFD systems:

- Energy Efficiency: it take the guesswork out of adjusting motor speed to minimize energy use.

- Improved Motor Performance: it prevents motor overheating and adds a significant efficiency component to OEM-level efficiencies.

- Extended Life of Equipment: In contrast, a soft starter only covers the initial ramp-up startup element of a system, whereas allows for total control of speed throughout the entire operational range.

What is a Soft Starter?

Soft starters perform the function of an electrical device, limiting the inrush current (starting an electric motor). A soft starter reduces electrical and mechanical stress on the motor and shaft, making it an ideal choice for motors that need smooth starts but do not need variation in speed throughout their operation.

AKNItech offers organizations solutions for soft starters and can help industries with the smooth, controlled startup of their motors.

How Soft Starters Work

A soft starter operates on the simple premise of limiting the start-up voltage to the motor. By ramping up the speed of the motor and limiting the amount of stress both mechanically and electrically. Soft starters do a great job of lowering the stress, specifically at the start-up of an operation where the motor comes up to speed. Soft starters do not provide variable speed control capabilities as VFDs do.

Soft Starter vs VFD – Important Differences

Soft Starters and VFDs are both used for motor control; however, their functionality and applications are very different. Soft starters apply voltage to a motor in a gradual fashion to start it and thus reduce mechanical stress, whereas VFDs provide you with soft start capability while also allowing for continued speed control through a motor’s operation.

Benefits of VFD in Comparison to Soft Starters

VFD offers more than a soft start. By continually adjusting motor speed relative to demand, the net result becomes energy efficiency and ultimately savings. it also provide better control via a SCADA system than soft starters by allowing the operator to manually/amenable resize throughput in real-time.

When to Choose Soft Starter vs VFD for Your Facility

If you determine that your motor control application needs motor speed controls after startup, then a VFD is the best answer. If the motor control application is a relatively simple start-up operation without the need for full speed control, then a soft starter will work.

AKNItech assists heavy industry in deciding on a soft starter vs VFD based on operational requirements, energy goals, and overall long-term cost. We provide consultative services to choose the right motor control solution for any facility.

Why AKNItech for VFD and Soft Starter Solutions?

AKNItech supplies VFDs, soft starters, and custom solutions to optimize energy usage and operational efficiency. Here are the signals for the correct partner for your motor control needs:

- Customization: We understand that every application is unique. AKNItech customizes solutions at a low Price for your operational context.

- Comprehensive Support: From initial consultation through system design, installation, and maintenance, AKNItech offers fully integrated support.

Conclusion: Achieving Efficient Power Management with AKNItech

VFDs and soft starters are both fundamental tools for power management purposes, but the appropriate solution for your application will depend on what you are trying to accomplish.

Get in touch with AKNItech today and let us know how we can help you optimize your power management systems with either VFD technology, PLC products, or soft starters.

Or Call Us: 7389942094