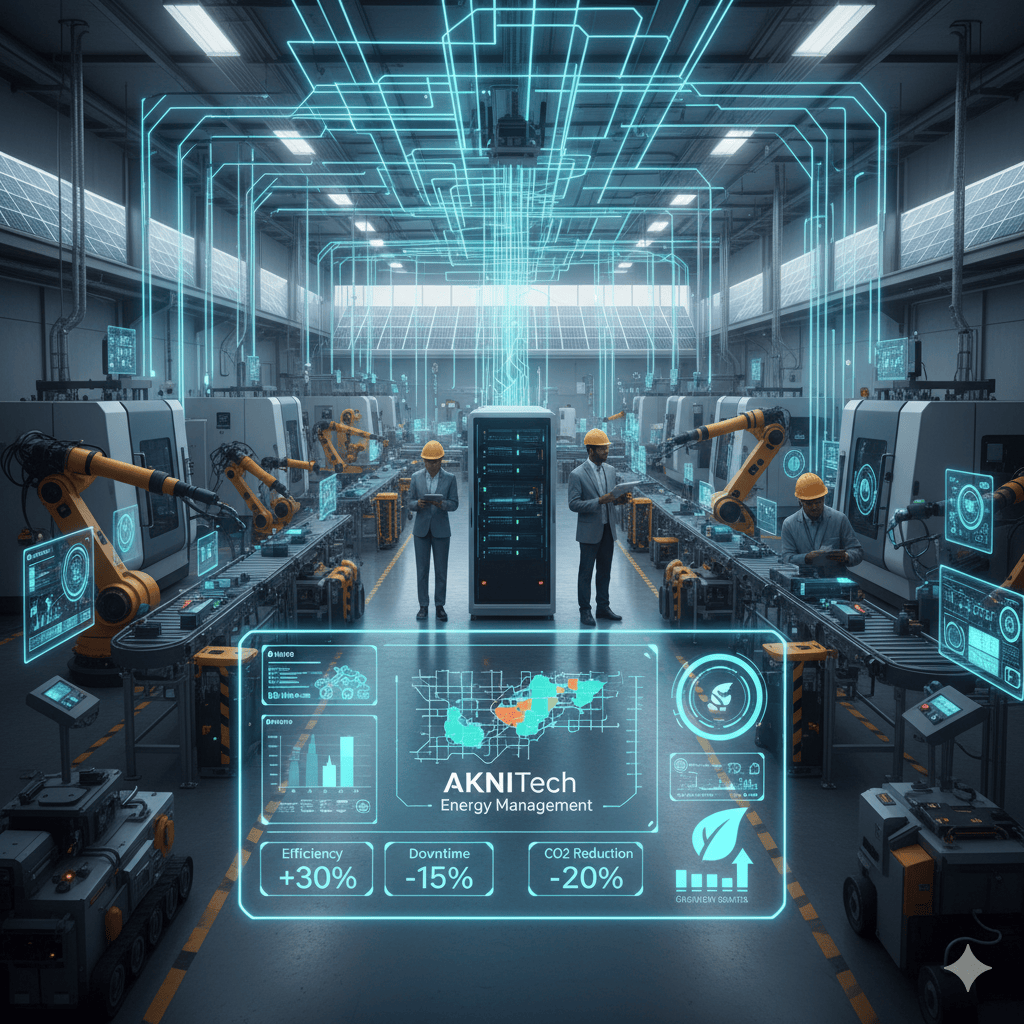

Energy efficiency is an increasingly important consideration for utility plants and industrial facilities. The use of IoT System Management combined with PLC and SCADA systems provides facilities with real-time data monitoring and automation, removing barriers to enable the facility to optimize energy consumption, make cost savings, and improve overall operational performance. At AKNItech, we are well-versed in implementing these systems and tool sets as solutions to support businesses in improving energy management.

What is IoT System Management, and how do we use it to improve energy efficiency?

IoT system Management encompasses deploying and managing IoT devices within/in conjunction with other systems. This process entails collecting and analyzing data for process automation and ensuring that efficient processes occur. For energy-intensive actions, whereas IoT system management will enable real-time monitoring and optimization, with the appropriate automation, a facility can quickly identify when they are consuming energy inefficiently, or detect waste immediately at the device itself. AKNItech focuses on custom IoT system Management solutions that are integrated with SCADA and PLC systems to maximize your energy use and reduce waste.

Why are SCADA and PLC important on the IoT System Management path?

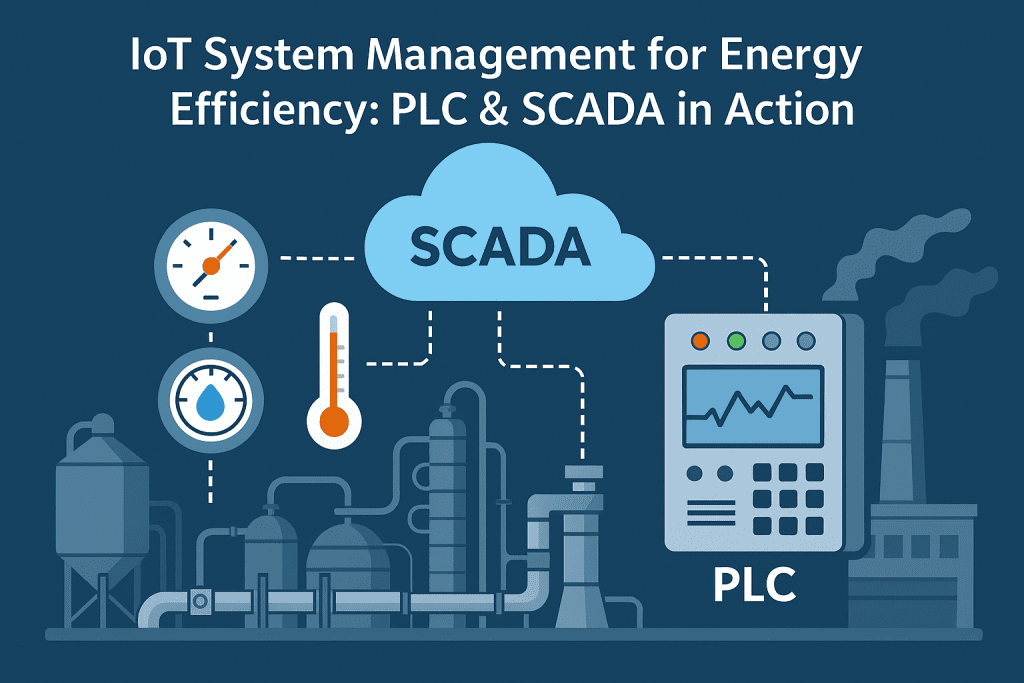

SCADA [Supervisory Control and Data Acquisition] is critical to modern industrial automation, combining different control systems by connecting the best IoT devices and solutions. SCADA systems analyze, present, and derive control actions based on data collected from IoT devices, providing operators with the tools they need for monitoring and controlling their energy use.

AKNItech helps connect IoT devices with SCADA systems to help you provide real-time feedback and/or control for energy consumption, all to keep your facility operating at optimum efficiency while consuming the least energy possible.

How SCADA and PLCs Work Together to Capitalize on Energy Management

SCADA Full Form in Electrical and Its Role in IoT

The full meaning of SCADA in electrical is: “Supervisory Control and Data Acquisition,” and it is the leading system used to monitor and control a plant’s operations. In an IoT system, SCADA online tools enable the plant to obtain data from IoT devices (sensors, meters, actuators, etc). These are utilized for things like the process monitoring of a water treatment plant operation and to control the energy distribution.

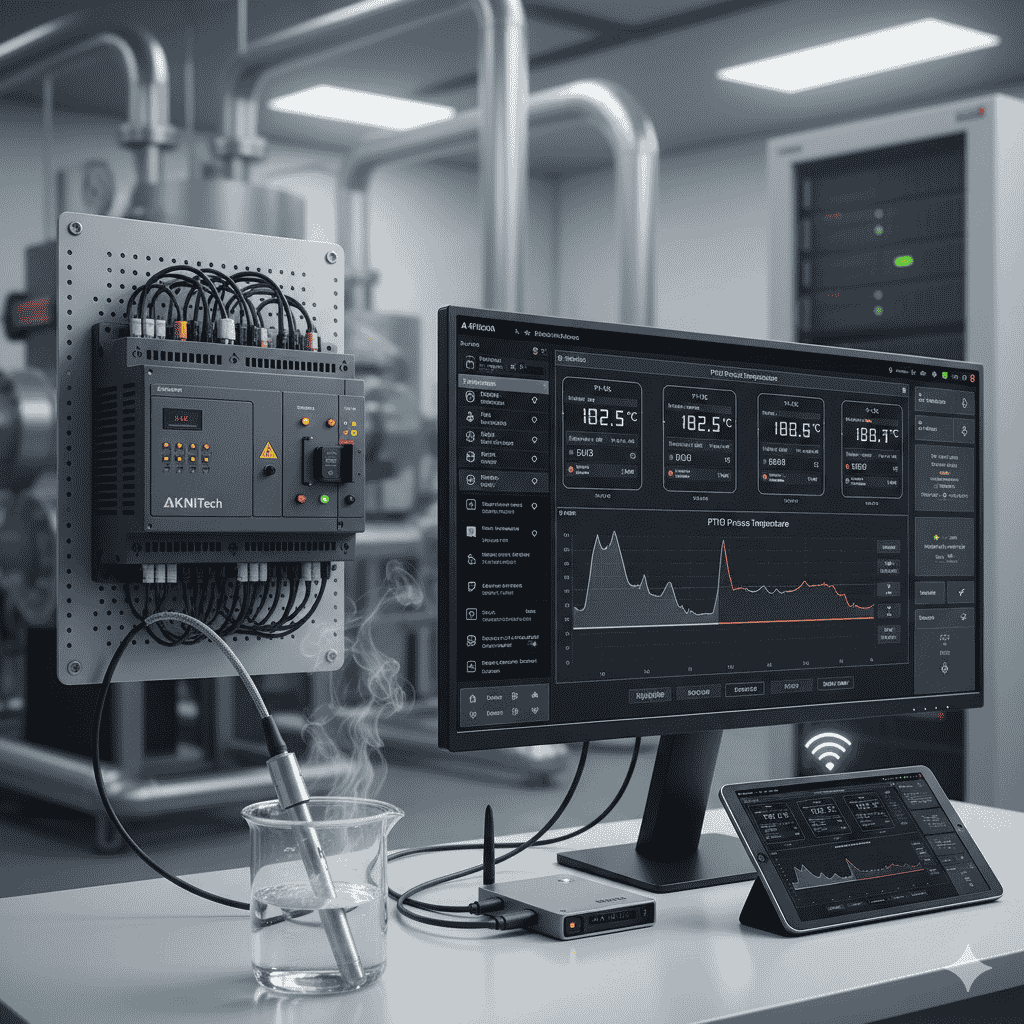

AKNItech’s philosophy is to provide the plant with SCADA in IoT, so the operation is fully integrated and allows operators to change their processes without lagging real-time adjustments based on feedback received from IoT sensors.

PLCs and SCADA Systems Working Together For Efficiency

PLC (Programmable Logic Controllers) are typically the main controller used to control machines and equipment in industrial facilities. Working with a SCADA system, SCADA and PLC work interoperability, which puts an intelligent edge for process automation and controls energy consumption.

AKNItech does not just provide PLC standalone systems or PLC systems that can be integrated and connected to SCADA, but we create PLC systems that offer integration of IoT, provide SCADA-optimized operations, and energy optimization.

Let solutions allow your plant to automatically engage processes based on the IoT-sensed data received in real-time, allowing for less human interaction and an energy-efficient plant.

SCADA Architecture and Energy Optimization

The SCADA Architecture diagram illustrates how data flows from the device to the control center devices.

An example in energy systems is that IoT-enabled SCADA systems track energy consumption and identify other inefficiencies. By providing access to IoT device management along with PLC integration, AKNItech controls the data flow from the energy to ensure it seamlessly flows to energy management to stop waste and reduce costs.

Additionally, integration with SCADA systems allows for the communication and transmission of information between devices and improved communication for control at the plant. The SCADA app also supports remote access to view real-time data, provides plant management to allow for visual adjustments from anywhere.

Energy Efficient with PLC Integration in Utility Plants

One of the major aspects of PLC systems is their capability for the automation of the process, without the involvement of human labour. e.g., to provide IoT with PLC integration with utility plants or similar systems where the goal is to achieve as little manual labour, if possible increase system reliability in on-time delivery of energy to the customer, and optimize energy usage.

AKNItech’s PLC systems provide advanced solutions for energy-intensive operations such as water treatment facilities and power systems, offering the most effective energy management through complete automation.

With IoT device management, AKNItech allows utility facilities to measure energy usage over time, ensuring operations are always within their budgets and in compliance with goals for environmental sustainability.

Benefits of SCADA and PLC Integration for Energy Efficiency

Advantages of SCADA

- There are many benefits of energy management with a SCADA System:

- Real-time data from IoT devices allows management to view energy usage.

- Automation of processes such as water treatment and chemical dosing for enhanced efficiencies.

- IoT sensors can provide predictive maintenance to back up SCADA, allowing facilities to work more safely when low energy or downtime adjustments can occur either operationally.

- AKNItech’s SCADA functional automation allows a utility plant to minimize energy cost while maintaining safety and performance for facilities to operate.

Benefits of PLC and IoT Integration

PLC systems with IoT devices have one substantial improvement for energy management, and they include:

- Enhanced automation: Automated flows of water, the energy distribution to operations, and processes now include automated system operations with PLC that can help to locate optimal energy uses.

- Remote Control: When a SCADA system is integrated with PLC, an operator can demonstrate precise measurements from energy usage to responsive locations, allowing better interventions and more operational flexibility.

- Energy reductions: By integrating PLC into energy management, automated process adjustments through SCADA will reduce energy costs and waste.

The Future of IoT System Management and PLC Integration

The integration of SCADA and IoT device management will continue to drive the future of energy management of industrial plants. As technology progresses, it is our priority at AKNItech to provide progressive solutions that result in greater energy efficiency, cost reductions, and sustainability in operation. With experience in PLC integration, we can ensure that utility plants are going to be built for the demands of 2025 and beyond.

Why select AKNItech for your IoT System Management and PLC Integration?

AKNItech is your trusted provider for IoT system management and PLC integration to optimize your energy efficiency. So, why trust AKNItech to deliver a solution?

- Expertise: We are experienced in integrating IoT hardware and technology with PLC systems, offering tailored solutions that are designed to meet your plant’s unique application requirements.

- Bespoke Solutions: We recognize the idiosyncrasies of each utility plant and provide solutions specifically designed to support your utility’s operations.

- End-to-End Support: AKNItech provides design to maintenance services to ensure your plant is running efficiently, effectively, and sustainably.

Make AKNItech part of your puzzle to optimize energy efficiency

As utility plants become more complex, the need for IoT system management and PLC integration to support energy efficiency and cost reduction becomes a necessity. AKNItech can be your partner for smart automation to assist your utility plant towards its energy goals.

For More Details, You Can Contact Us

Or Call Us: +91-7389942094