If you run a process-driven business, maybe in FMCG, chemicals, or pharma, you already know the challenges in 2025. Operations are getting more complex, teams are stretched thin, and there’s constant pressure to improve efficiency without cutting corners.

In the middle of all this, sticking to old systems, manual logs, delayed alerts, and outdated panels just slows you down. That’s why more and more factory owners are moving toward IoT device control, MIS panels, and PLC automation. These tools aren’t just buzzwords; they help you stay in control, avoid downtime, and get a better handle on what’s happening inside your plant.

What Is IoT Device Control & How It Works Inside a Factory Setup

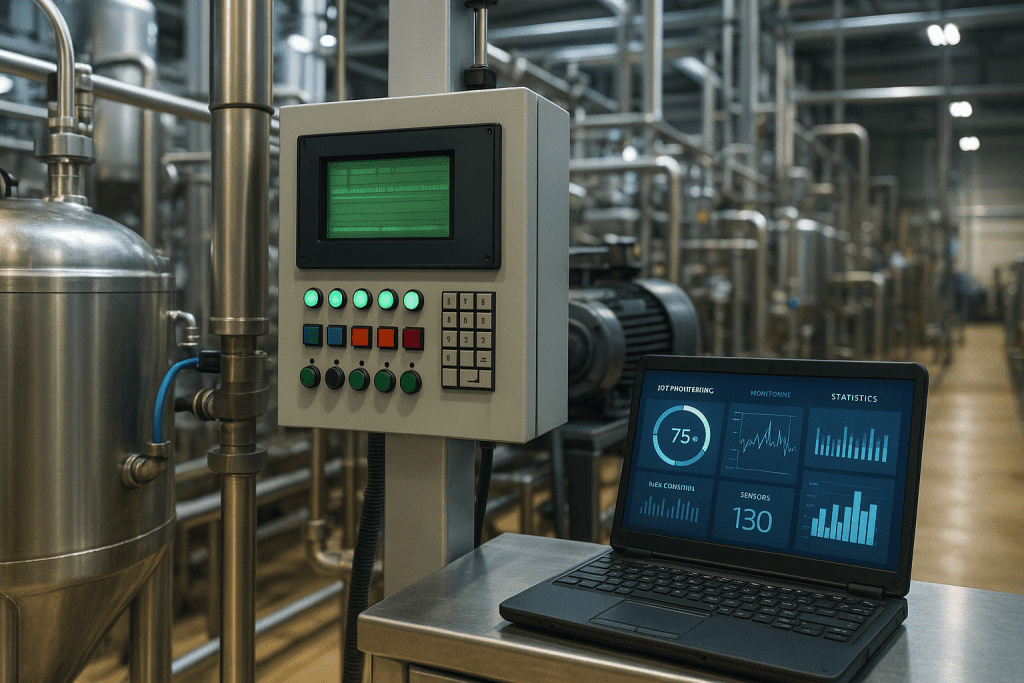

IoT device control means you’re able to control and monitor your machines, valves, sensors, and motors, without being right next to them. You get live data, remote access, and instant alerts if something’s off.

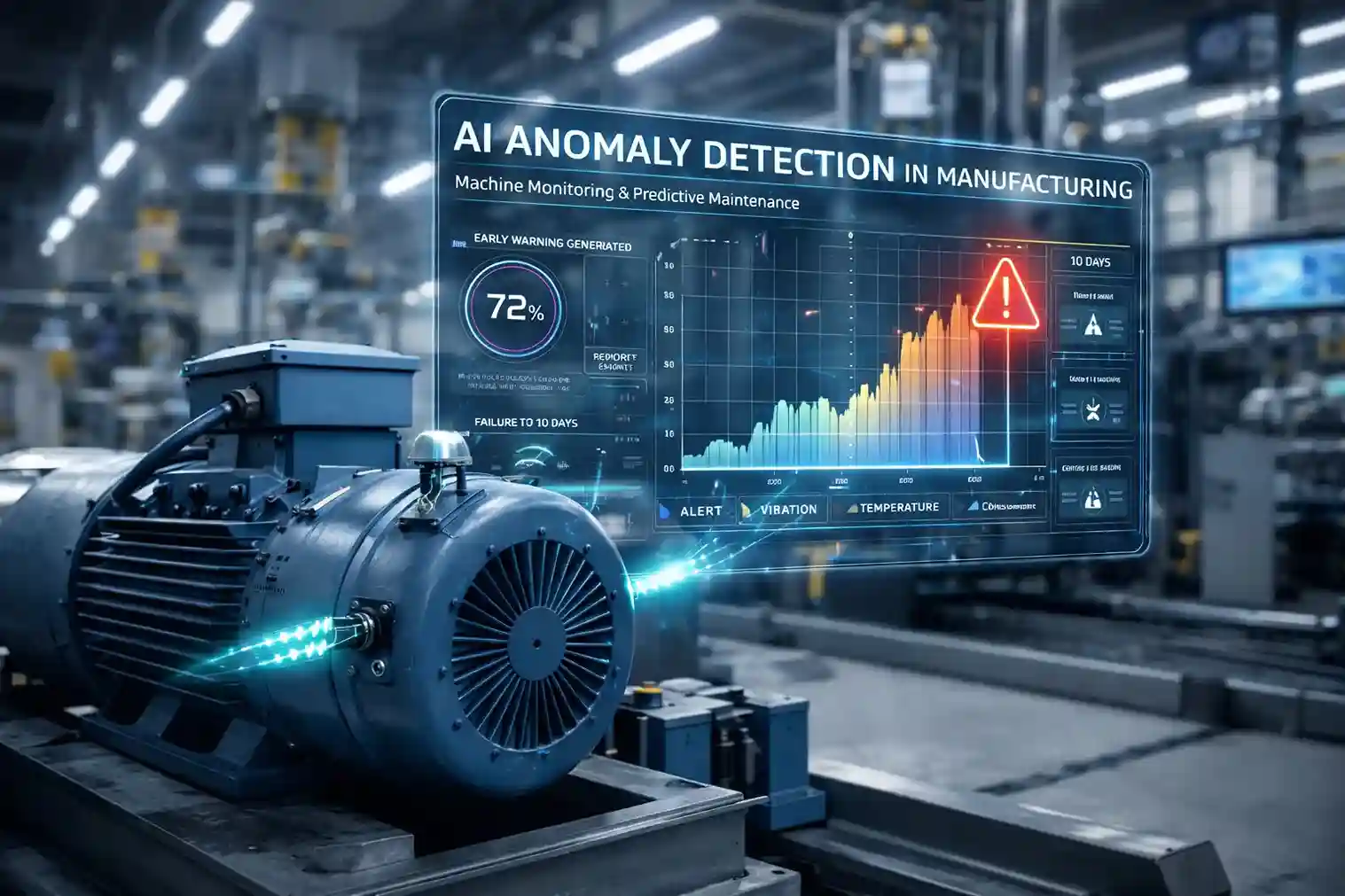

For example, if your mixing tank starts overheating or a motor runs longer than expected, you’ll know instantly. With IoT device management and a good setup of IoT monitoring devices, you can either fix the issue remotely or shut things down before damage is done.

The point is simple: You stay ahead of problems instead of reacting to them.

The Role of MIS Panels: Turning Raw Data into Useful Decisions

Here’s where a MIS panel makes life easier. It’s like a dashboard that collects everything going on in your plant, production speed, equipment uptime, energy usage, even batch details, and puts it into clean reports.

Instead of your team running around filling in spreadsheets or figuring out what happened yesterday, MIS automation gives you live updates and shift-wise reports. And when your quality team asks for documentation? You already have it.

Whether you’re reviewing your MIS production output or just trying to find the source of an issue, these panels give you clarity you can use.

How PLC Automation Keeps Your Core Operations Running Smoothly

PLC automation has been the backbone of industrial control for decades, but it’s getting smarter now.

A PLC (Programmable Logic Controller) takes care of repetitive tasks and machine operations, turning motors on/off, managing heaters, and controlling sequences. Your PLC panel or PLC electrical panel handles all of this based on a program written in one of many PLC programming languages (also called PLC language).

When done right, it works quietly in the background, keeping everything running without human involvement. And when you add PLC integration with IoT, your systems become even more responsive, automatically adjusting based on real-time data from sensors or devices.

Bringing It All Together: Why You Need All Three – PLC + IoT + MIS

These three systems work better together:

- PLC automation runs the machines

- IoT device control keeps you updated and lets you react in real time

- MIS panels help you understand the data and make better calls

It’s like giving your factory a brain, eyes, and a nervous system, all working together. You can catch issues early, reduce downtime, and improve quality without constantly firefighting.

Real-World Example: What Changes When You Upgrade

Here’s a simple example. One of our clients in the FMCG sector was facing daily production delays. Machines were overheating, and they were using manual logs to track output, often catching problems too late.

We stepped in with PLC integration, IoT monitoring, and MIS automation.

- Now, they get alerts before equipment fails

- Operators adjust machines through remote IoT device control

- The plant manager starts each day with a full MIS production report

- Uptime went up. Stress went down. And everything is traceable

It wasn’t magic—it was just the right systems working together.

2025 Trends: What We’re Seeing Across the Industry

If you’re wondering whether you’re the only one considering this kind of setup, you’re not. More factories are upgrading now than ever.

Here’s what’s driving it:

- Managers want less dependency on manual intervention

- Compliance is getting stricter—real-time logs help

- IoT systems management is becoming a standard, not a luxury

- Cloud-based IoT device management platforms are easier to set up

- Smart PLC electrical panels now offer built-in energy tracking

- Everyone wants fewer surprises and better reports

If you’re not automating now, your competitors probably are.

Why AKNItech Is the Right Partner to Help You Make the Shift

Look, we get it. Upgrading systems can feel overwhelming. But that’s where our team comes in.

At AKNItech, we don’t just sell equipment, we set up complete systems that work together. From custom PLC panels to IoT-based control to clean, clear MIS automation dashboards, we design everything around your plant, your workflow, and your team.

We work with process industries across India to make operations smarter, leaner, and easier to manage—without breaking the bank or overcomplicating the tech.

Let’s Build Your Smart Factory, One Intelligent System at a Time

If you’re still running on manual logs, scattered systems, or constant breakdowns, it’s time for a change.

With AKNItech, you get full-stack support: PLC automation, IoT monitoring, and MIS production solutions that are built to make your work easier, not harder.

Let’s talk. Book your free consultation today and take the first step toward building a smarter, more reliable factory.