In the era of Industry 4.0, industries are increasingly evolving toward smart systems that rely on data, connectivity, and automation. At the center of this shift is the Internet of Things (IoT), which is revolutionizing industrial automation across multiple industries.

From increased process automation to reduced downtime and better use of resources, IoT in the industrial automation sector is more than a trend—it’s become a competitive requirement. Below, we get into how IoT facilitates efficiency and productivity on the industrial job site.

What is IoT Industrial Automation?

The Internet of Things (IoT) is the network of physical things that are connected to the internet and can store or share data. When we consider industrial automation, IoT interconnects machines, sensors, controllers, and systems to form a real-time data ecosystem.

This type of intelligent device supports closed-loop process control, real-time access to information, and automation of complex tasks, transforming outdated manufacturing lines into intelligent production systems.

How IoT Enhances Efficiency in Industrial Automation

- Monitoring and Control in Real-Time

Sensors on the Internet of Things are continually pulling in data on machines, assembly lines, and factory floors. This allows the monitoring of performance, temperature, pressure, speed, and other essential readings while the operation is in progress.

Based on this data, companies can:

- Identify irregularities immediately

- Adjust quickly against stalling out

- Reducing emergency response time for emergencies

With visibility at this level, more efficient process automation and control can be achieved, reducing the risk of human error.

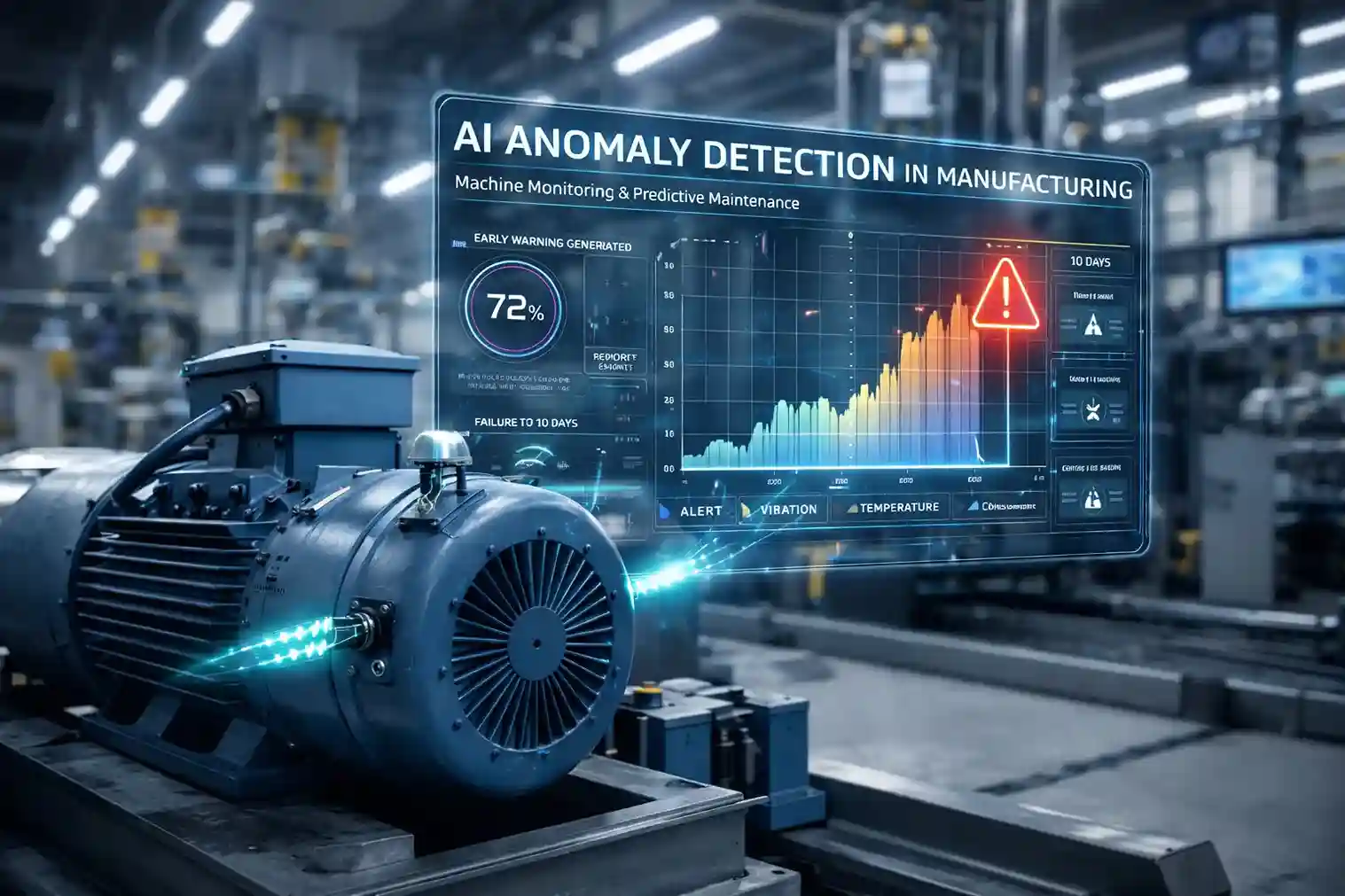

- How Predictive Maintenance Saves Downtime

Unplanned downtime is costly. Predictive maintenance for IoT does this: instead of repairing the equipment when it breaks, it repairs it before it breaks.

Benefits include:

- Extended machinery lifespan

- Lower maintenance costs

- Less production downtime

Rather than fixing an issue after the fact, predictive maintenance allows you to avoid the issue altogether – a significant leap in operational efficiency.

- Optimized Energy Consumption

Energy-intensive industries are particularly well placed to reap the benefits of IoT. They can do so using smart meters and energy sensors that:

- Track watts per computer

- Identify energy waste

- Inform operational changes

Through the implementation of Industrial IoT into industrial automation, such companies can save power, cut costs, and minimize their environmental footprint while maintaining output at its peak capacity.

- Data-Driven Decision-Making

Each of these IoT-connected things produces data. Type of data: This data can be visualized and analysed through dashboards, which permit:

- Better resource planning

- Process optimization

- Informed strategic decisions

These types of insights are not only increasing productivity but also the agility that businesses need to remain ahead when faced with stiff competition.

Applications of IoT in Process Automation

Some relatable real-world examples where IoT meets process automation:

- Smart Manufacturing: Automatically reconfiguring assembly lines depending on sensor inputs.

- Remote Equipment Monitoring: Monitoring of a machine’s health and performance can be done regardless of its location.

- Inventory control: sensors in check supplies and re-order them automatically.

- Quality Control: Defects are monitored in real-time, which means less waste and rework.

Case studies: Energy efficiency in the IoT. These examples show how IoT provides control, accuracy, and speed in industrial applications.

Limitations in IoT Usage

However, despite the merits, the application of IoT for industrial automation is not without challenges:

- Security Risks: The more connected things you have, the more opportunities hackers have to access your house.

- Legacy System Integration: Various sectors rely on obsolete machinery that is not yet ready for IoT.

- 1.2 Skilled staff: Success in the adoption of IoT, data analysis, and automation tools requires staff who are proficient in them.

But these obstacles can be managed with smart planning and skilled support.

How Aknitech Empowers Smart Industrial Automation

About Us Kicking its way out of the cobwebs of an antiquated system, the core of Aknitech was born to address your unique IoT needs specifically. Whether you want to retrofit your old systems or create a smart factory from a clean slate, we provide you:

- Wellsite surveillance systems, such as real-time data monitoring systems

- Process control as an energy-saving measure

- Predictive maintenance integration

- Complete industrial automation services in Bhopal and India

It is our mission to assist you in optimizing your efficiency and productivity utilizing the latest in automation technology.

Future Trends: What’s Next for the IoT and Industrial Automation?

In the future, we anticipate the development of much more sophisticated technologies:

- AI-based Automation for Self-Learning Systems

- Edge computing for low-latency and better real-time decisions

- A factory of the future where machines are capable of autonomous end-to-end operations themselves

The IoT is going to be one of the effective and plasma posts of smart industries of the upcoming era.

The inclusion of IOT in industrial automation is at an inflection point functioning of industries. With real-time tracking and predictive maintenance, smart energy and manufacturing are disrupted by IoT towards agile and efficient systems.

When you’re ready to take your operations to the next level and take advantage of next-gen process automation, choose Aknitech — your trusted automation company.

Let’s create smarter industries together. Click Here