Industries across India are transforming rapidly as factories move from manual operations to automated, interconnected, and data-driven systems. Modern production lines rely on machines that can think, react, and communicate with precision. In this environment, PLC and SCADA for engineers has become one of the most essential skill areas, because industrial PLC systems and SCADA software have become the backbone of automation. For engineers-whether electrical, mechanical, electronics, or instrumentation-learning PLC programming and SCADA is now essential for building a strong and future-proof career.

What Are PLC and SCADA?

PLC – The Brain of Industrial Machines

A PLC is an industrial computer designed to control machines like motors, pumps, conveyors, heaters, and automated robots. Engineers use PLC programming languages such as Ladder Logic and Function Block Diagram to write logic that enables machines to operate automatically. Because of their reliability, PLCs are preferred by small factories as well as large programmable logic controller manufacturers around the world.

SCADA – The Eyes and Dashboard of the Plant

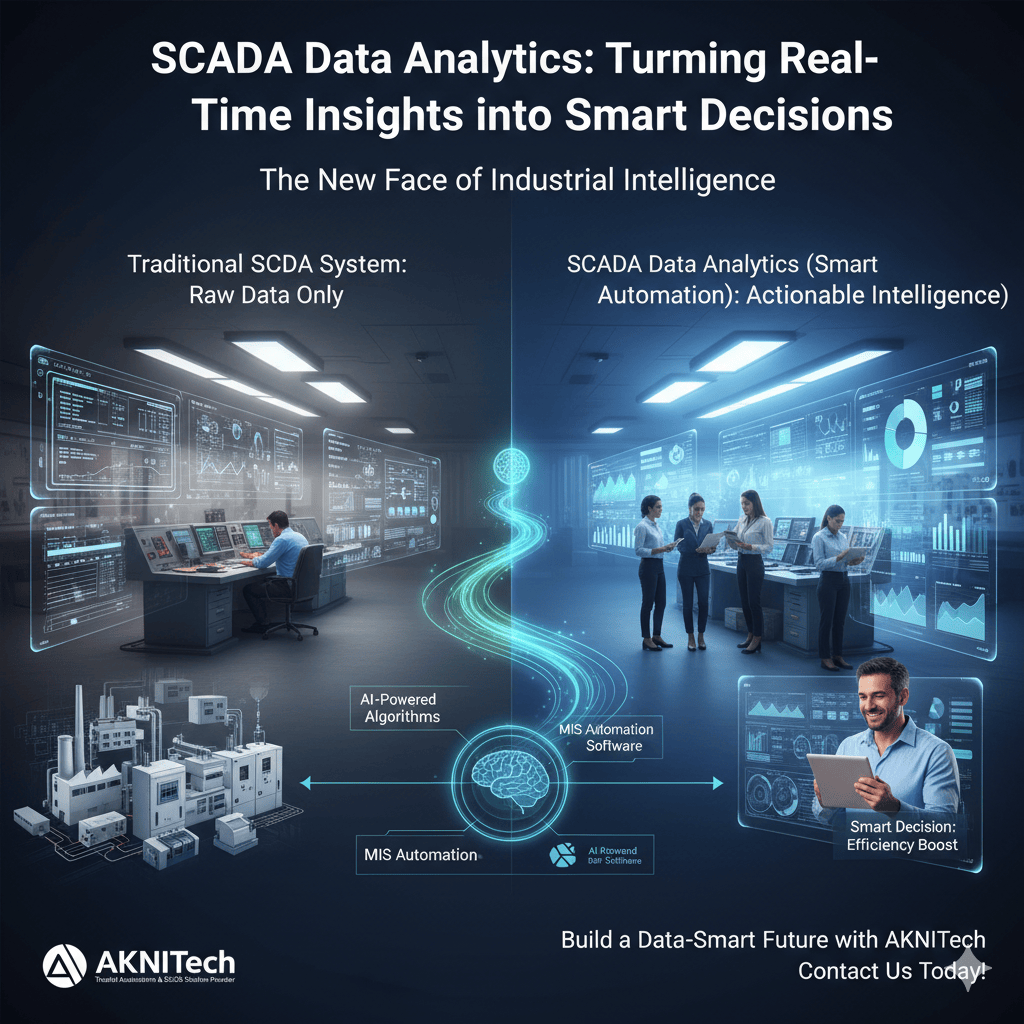

SCADA is a powerful supervision and monitoring system used to track real-time industrial data. It logs production performance, displays alarms, and allows engineers to remotely control plant operations. Modern SCADA software also integrates seamlessly with cloud dashboards and smart devices, giving engineers complete visibility of the plant from anywhere.

When PLC controls the process and SCADA visualizes it, the integration forms a complete HMI SCADA PLC ecosystem.

Key Features of PLC & SCADA Systems

High Reliability in Harsh Industrial Environments

Industrial PLC systems are built to withstand heat, vibration, electrical noise, and dusty conditions. Their durable PLC control panel components ensure that machines operate smoothly even during continuous production.

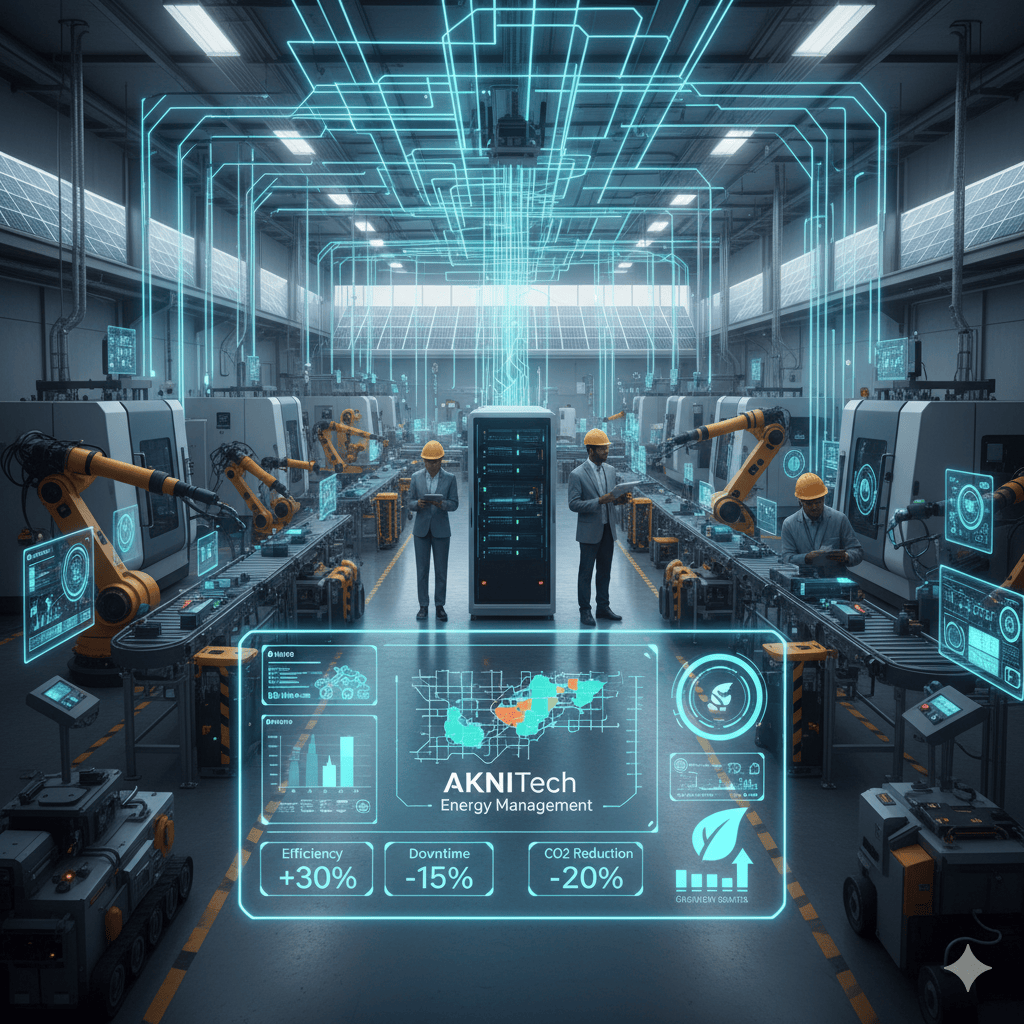

Real-Time Control and Monitoring

PLCs respond immediately to sensor inputs, while SCADA updates dashboards instantly. This real-time interaction helps engineers detect process deviations quickly and maintain high efficiency across the plant.

Modular & Expandable Architecture

PLCs support modular cards, making it easy to expand systems when new machines are added. SCADA software can also scale from small panels to a large facility. This flexibility is why most PLC manufacturers in India design PLCs with customizable modules.

Compatibility with Multiple Protocols

Modern automation systems support SCADA protocols in IoT like MQTT, Modbus TCP, and OPC UA. These protocols allow PLCs, sensors, HMIs, and SCADA servers to communicate efficiently.

Remote Access & Cloud Monitoring

SCADA systems today offer cloud connectivity and mobile access. Engineers can troubleshoot machines remotely, making operations smoother and minimizing downtime.

These features make PLC–SCADA essential across every industrial sector.

How PLC and SCADA Work Together

PLC Executes the Logic

Engineers use PLC HMI programming to execute machine operations like motor control, sequential actions, and safety interlocks. PLC ensures the machine works exactly as required for the production process.

SCADA Supervises the Entire Plant

SCADA software collects data from all PLCs, displays trends, manages alarms, and allows operators to control devices from a central dashboard.

Combined Control Creates Full Automation

This combination of automation logic and plant-level visualization forms a complete industrial automation system – reliable, scalable, and efficient for all manufacturing environments.

Benefits of Learning PLC and SCADA for Engineers

Strong Job Opportunities Across Industries

Automation engineers with PLC programming and SCADA knowledge get more interviews and job offers because every industry now uses these technologies for maintenance, installation, and system upgrades.

Higher Salaries & Fast Growth

Companies value engineers who can reduce machine downtime and optimize performance. Engineers trained on industrial PLC and SCADA systems earn faster promotions and better salaries in automation roles.

Practical Understanding of Industrial Machines

Learning PLC–SCADA exposes engineers to real machine behavior, wiring methods, sensors, relays, and advanced PLC control panel components. This hands-on knowledge builds confidence during industrial projects.

Better Troubleshooting Skills

Engineers can detect faults by analyzing ladder logic, inspecting SCADA alarms, and tracing input/output signals. This makes them valuable problem-solvers inside factories.

Future-Proof Skillset for Industry 4.0

As companies adopt IoT, robotics, and smart factory solutions, PLC–SCADA knowledge forms the foundation for advanced technologies. It also helps engineers learn future areas like SCADA protocols in IoT and cloud-based automation.

Why Learning PLC & SCADA Is Important in 2025 – PLC and SCADA for Engineers

Rapid Automation Across India

Manufacturers want faster production, fewer errors, and consistent quality. Automation systems powered by PLC-SCADA make this possible.

Integration with IoT & Smart Factory Technologies

Modern automation platforms use SCADA protocols in IoT to connect sensors, machines, and dashboards through cloud systems. Engineers must understand these technologies to stay relevant.

Demand for Remote Monitoring & Control

SCADA enables supervisors to monitor plant operations from smartphones, control rooms, or remote cities-something every modern industry wants.

Shortage of Trained Automation Engineers

There are far fewer skilled PLC-SCADA engineers than what industries require. This demand gap ensures strong job security.

Mandatory Skill for Electrical, Mechanical, and Instrumentation Roles

Even junior engineering roles now mention PLC-SCADA knowledge as a requirement, not just an advantage.

2025 is the perfect time for engineers to learn these technologies before the industry becomes fully automated.

Applications of PLC and SCADA Across Industries

Manufacturing and Production Lines

PLC controls conveyors, packaging machines, robotic arms, assembly lines, and cutting systems. SCADA oversees the entire production output.

Power Plants and Energy Systems

SCADA monitors substations, switchgear, and turbines while PLC controls operations like breakers, feeders, and loads.

Water Treatment and Infrastructure

PLCs handle pumps, valves, and chemical dosing while SCADA monitors tank levels, water quality, and flow rates.

Food, Beverage & Pharma Sectors

Automation ensures hygiene, accuracy, and temperature control-critical for these industries.

Chemical and Oil Industries

PLC-SCADA maintains pressure, flow, safety interlocks, and emergency shutdown systems.

Automotive Manufacturing

Robotic arms, welding booths, and painting systems function through advanced PLC HMI programming and SCADA supervision.

This wide-ranging use is why engineers trained in automation can work in almost any industrial field.

Future Scope for PLC-SCADA Engineers

Industry 4.0 and Smart Manufacturing

Future factories will be interconnected, intelligent, and data-driven-built on PLC-SCADA foundations.

Robotics & Motion Control

Engineers with PLC-SCADA skills can easily expand into servo drives, CNC machines, and robotic automation.

Industrial IoT (IIoT)

Smart sensors, edge devices, and cloud SCADA systems rely on data collected from industrial PLC networks.

Predictive Maintenance & AI Integration

Future industries use data analytics to predict machine failures before they happen-something only PLC-SCADA enabled systems can provide.

High Global Opportunities

Countries like UAE, Germany, Canada, Malaysia, and Singapore hire automation engineers with great salary packages.

The future of automation is huge, and engineers who learn PLC-SCADA today will lead the industry tomorrow.

Conclusion

Learning PLC and SCADA is one of the most powerful steps an engineer can take in 2025. These technologies control how machines behave, how processes run, and how industries make decisions. Engineers with PLC-SCADA skills earn more, get better job opportunities, solve real industrial problems, and become ready for the future of smart manufacturing and Explore automation solutions here.